All-stage coal spontaneous combustion experimental system

An experimental system, coal spontaneous combustion technology, applied in the field of coal spontaneous combustion experiments, can solve the problems of poor repeatability, long experimental period, and increased difficulty of simulation and comparative research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

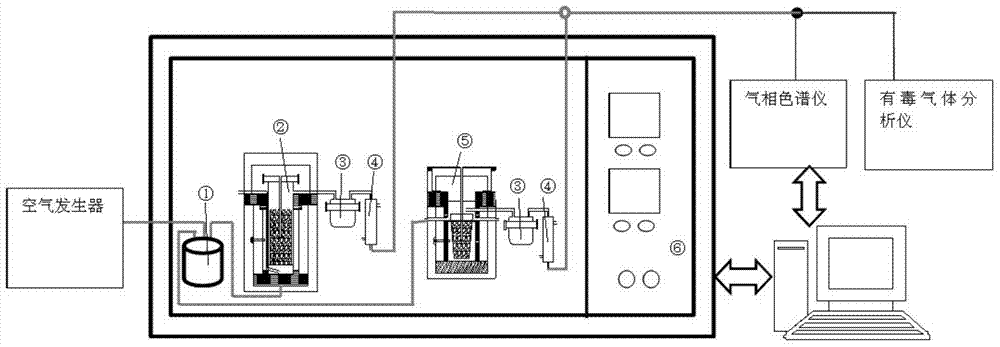

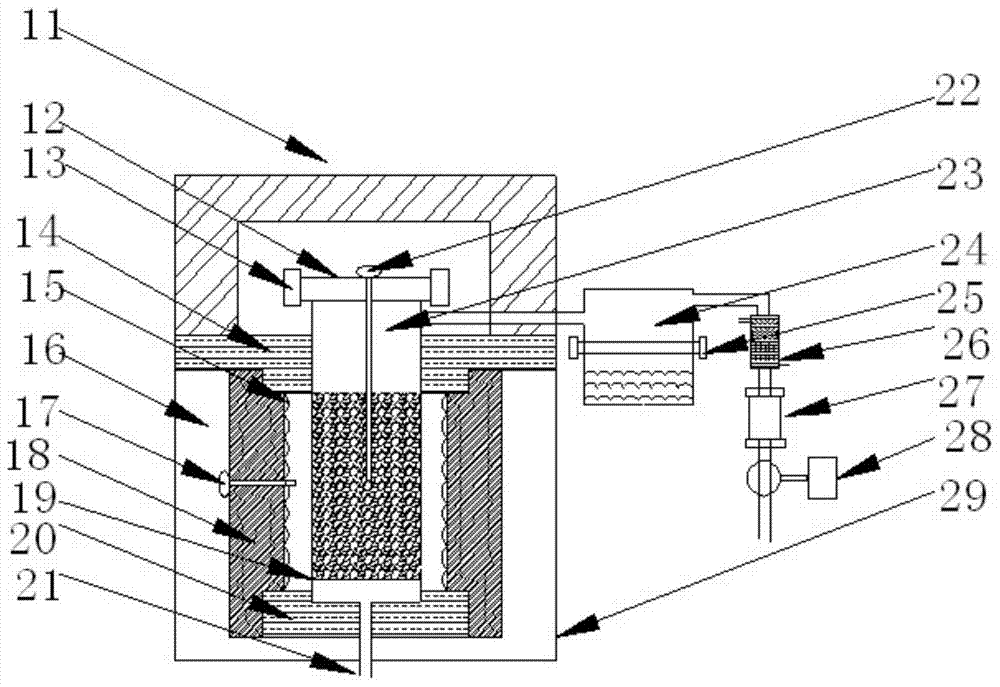

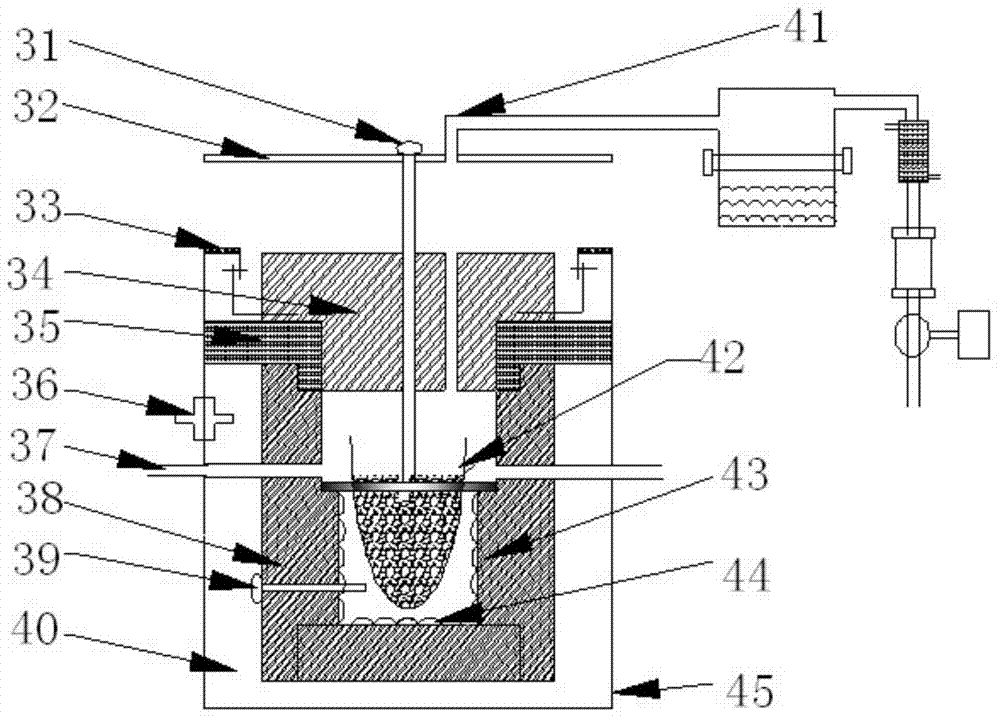

[0046] The overall structure of the whole-stage coal spontaneous combustion experimental system is as follows: figure 1 As shown, the experimental system is designed to use a maximum temperature of 1000°C, and the maximum temperature used in the experiment is 800°C.

[0047] 1. Materials:

[0048] The hearth of the experimental furnace is all made of mullite refractory material. Mullite (3Al 2 o 3 2SiO2 2 ) High-alumina refractory material with main crystal phase, Al 2 o 3 The content is between 72% and 75%. Mineral composition In addition to mullite, it also contains a small amount of corundum. The refractoriness is high, up to 1790 ° C, which is better than clay refractory materials. The starting temperature of load softening is 1600-1700℃, and the thermal shock resistance is good.

[0049] The furnace lining is all made of aluminum silicate refractory fiber felt. Aluminum silicate refractory fiber is a new fire-resistant and spill-retaining material developed in rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com