Thermocouple welding detection device

A welding detection and thermocouple technology, applied in the direction of measuring devices, using electrical devices, measuring electricity, etc., can solve the problems of low test efficiency, inability to meet the test, and manual testing of thermocouples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

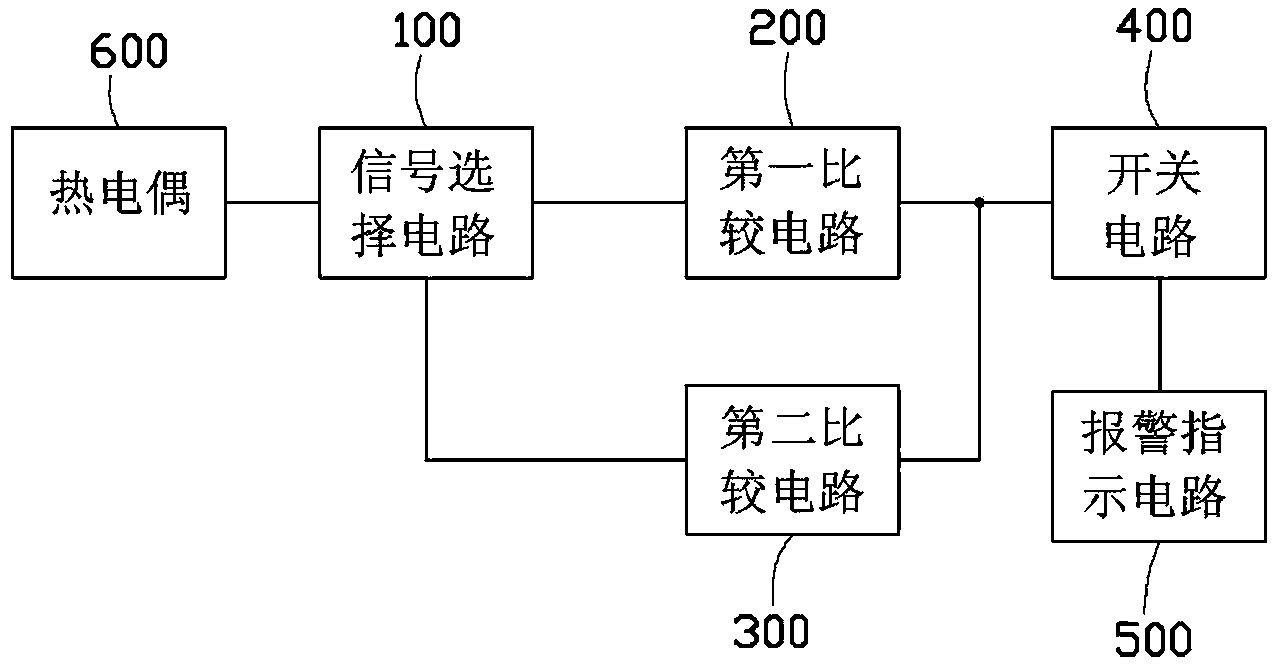

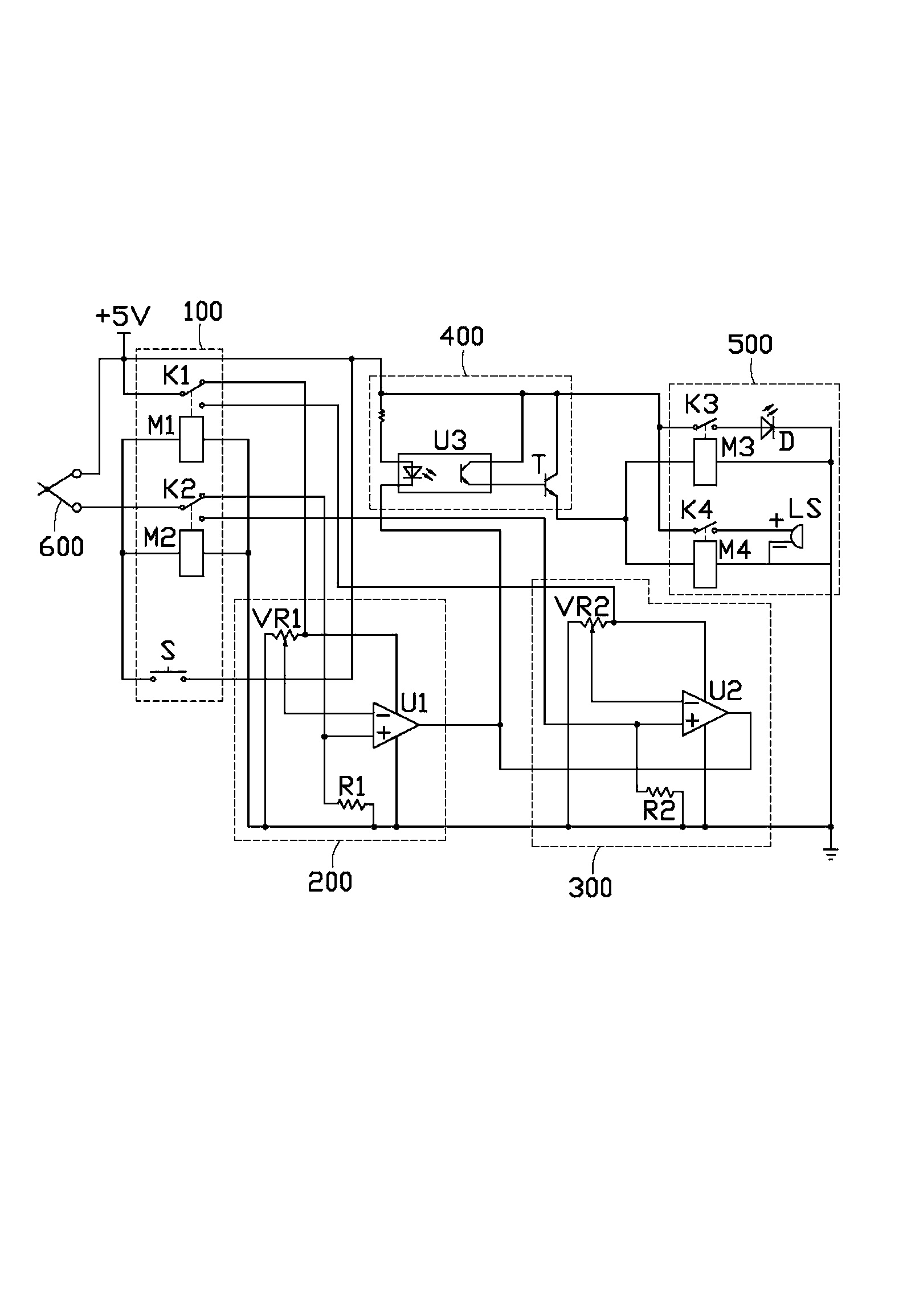

[0012] see figure 1 A preferred embodiment of the thermocouple welding detection device of the present invention is used to detect whether the thermocouple wire of a thermocouple 600 is welded normally. The thermocouple welding detection device includes a signal selection circuit 100, a first comparison circuit 200, A second comparison circuit 300 , a switch circuit 400 and an alarm indication circuit 500 . The signal selection circuit 100 is electrically connected to the thermocouple 600, the signal selection circuit 100 receives a selection signal, and outputs a first DC voltage to the first comparison circuit 200 or outputs a second DC voltage according to the selection signal. voltage to the second comparison circuit 300. The first comparison circuit 200 compares the first DC voltage with a first reference voltage and outputs a first control signal. The second comparison circuit 300 compares the second DC voltage with a second reference voltage and outputs a second contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com