Electrical axis optical calibration system of spaceborne microwave tracking-pointing radar and calibration method thereof

A calibration method, satellite-borne microwave technology, applied to radio wave measurement systems, instruments, etc., can solve problems such as inconvenient installation of cube mirrors, difficulty in ensuring installation accuracy, and complicated measurement work, so as to facilitate repeated measurements, improve calibration accuracy, The effect of ensuring high precision and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

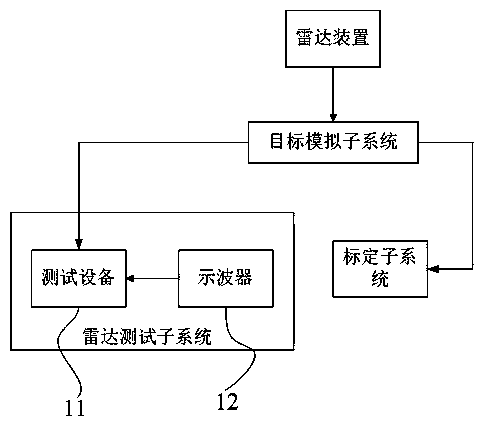

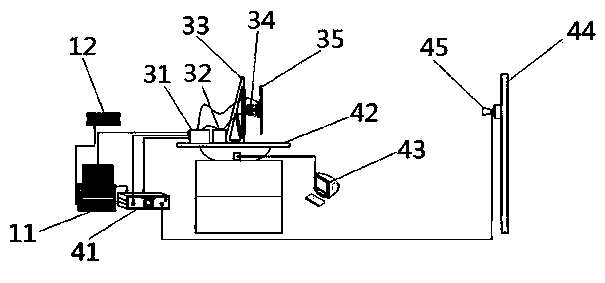

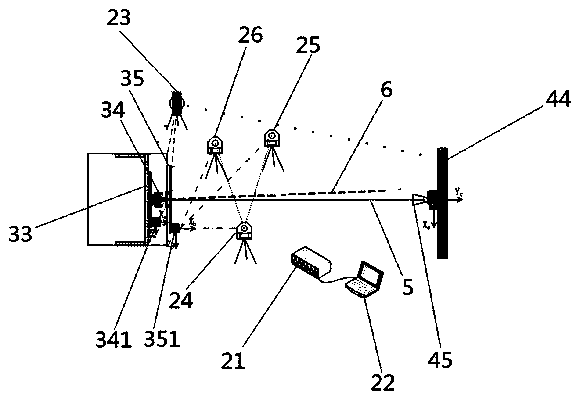

[0075] Such as figure 1 and figure 2 As shown, an electrical axis optical calibration system for a spaceborne microwave tracking and pointing radar includes a radar test subsystem, a calibration subsystem, a radar device, and a target simulation subsystem; the target simulation subsystem includes a target simulation source 41, and a two-dimensional test turntable 42. The two-dimensional test turntable controller 43 connected to the two-dimensional test turntable 42, the two-dimensional scanning frame 44 and the horn antenna 45 arranged on the two-dimensional scanning frame 44; the radar test subsystem includes the test equipment 11 and the oscilloscope 12 The oscilloscope 12 is connected with the test equipment 11; the radar device, the eye model horn antenna 45 and the test equipment 11 are connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com