Finite element analysis method of composite material

An analysis method and technology of composite materials, applied in the field of finite element analysis of composite materials, can solve the problems of difficult accurate analysis and calculation of composite materials, non-uniform winding directions of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

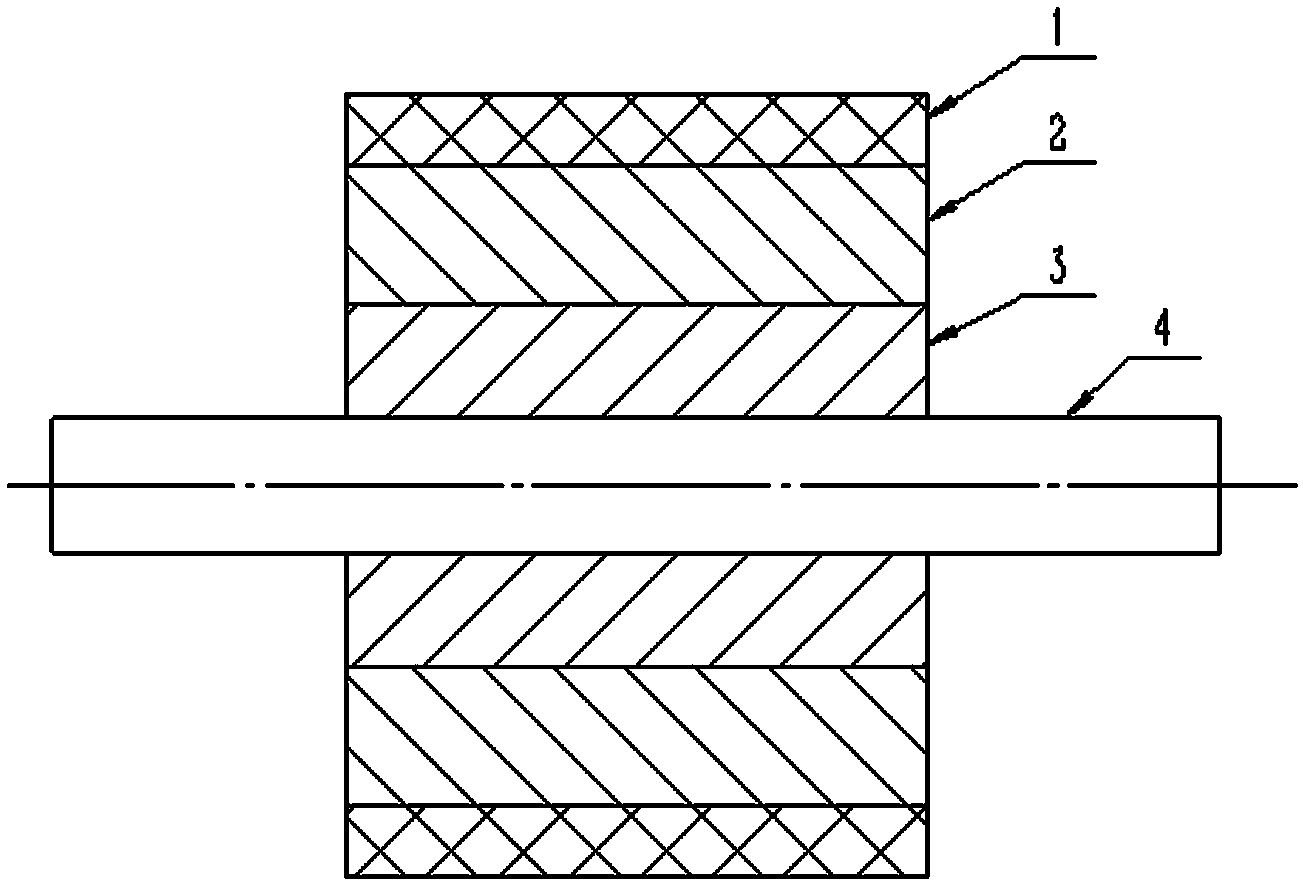

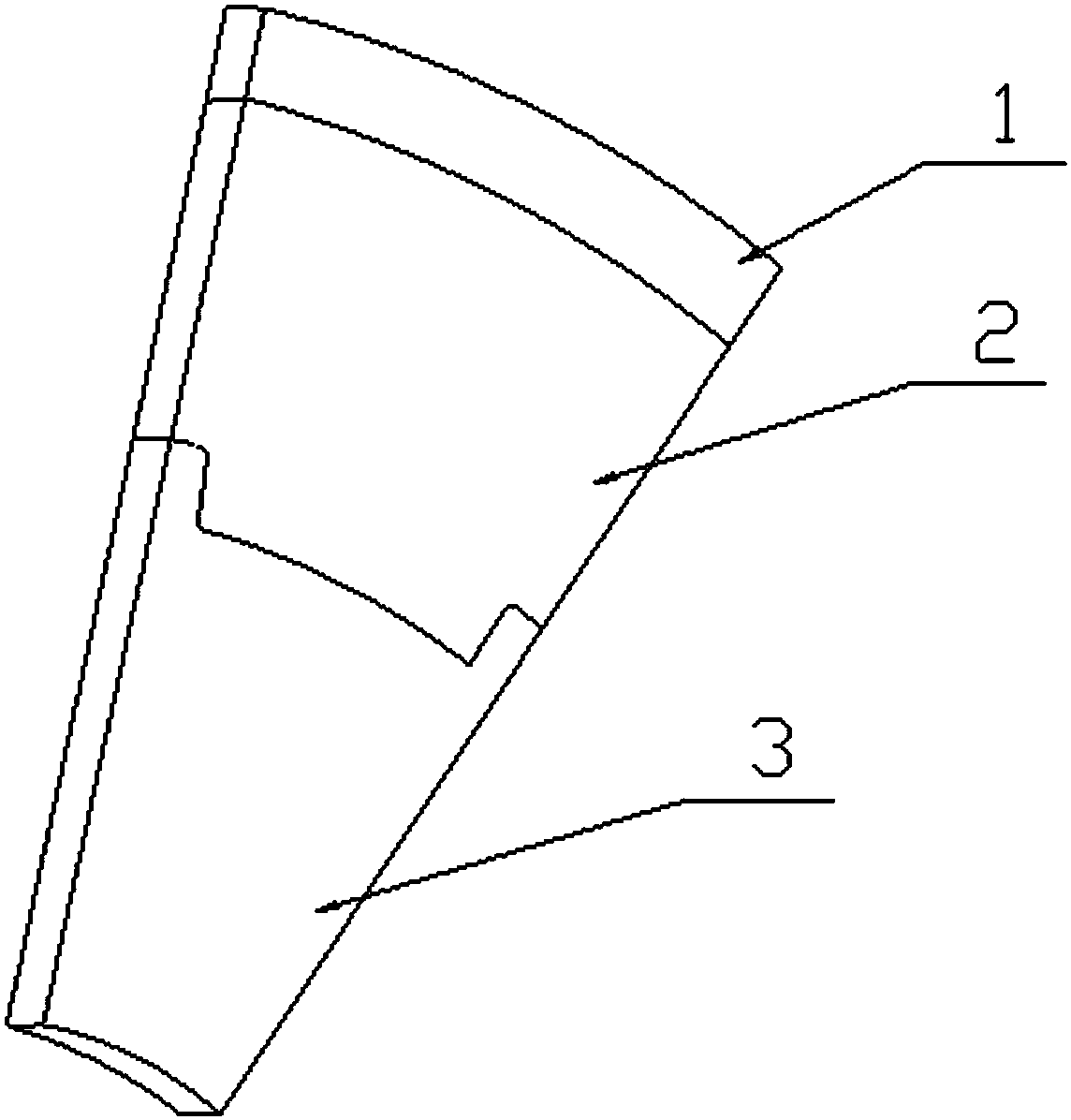

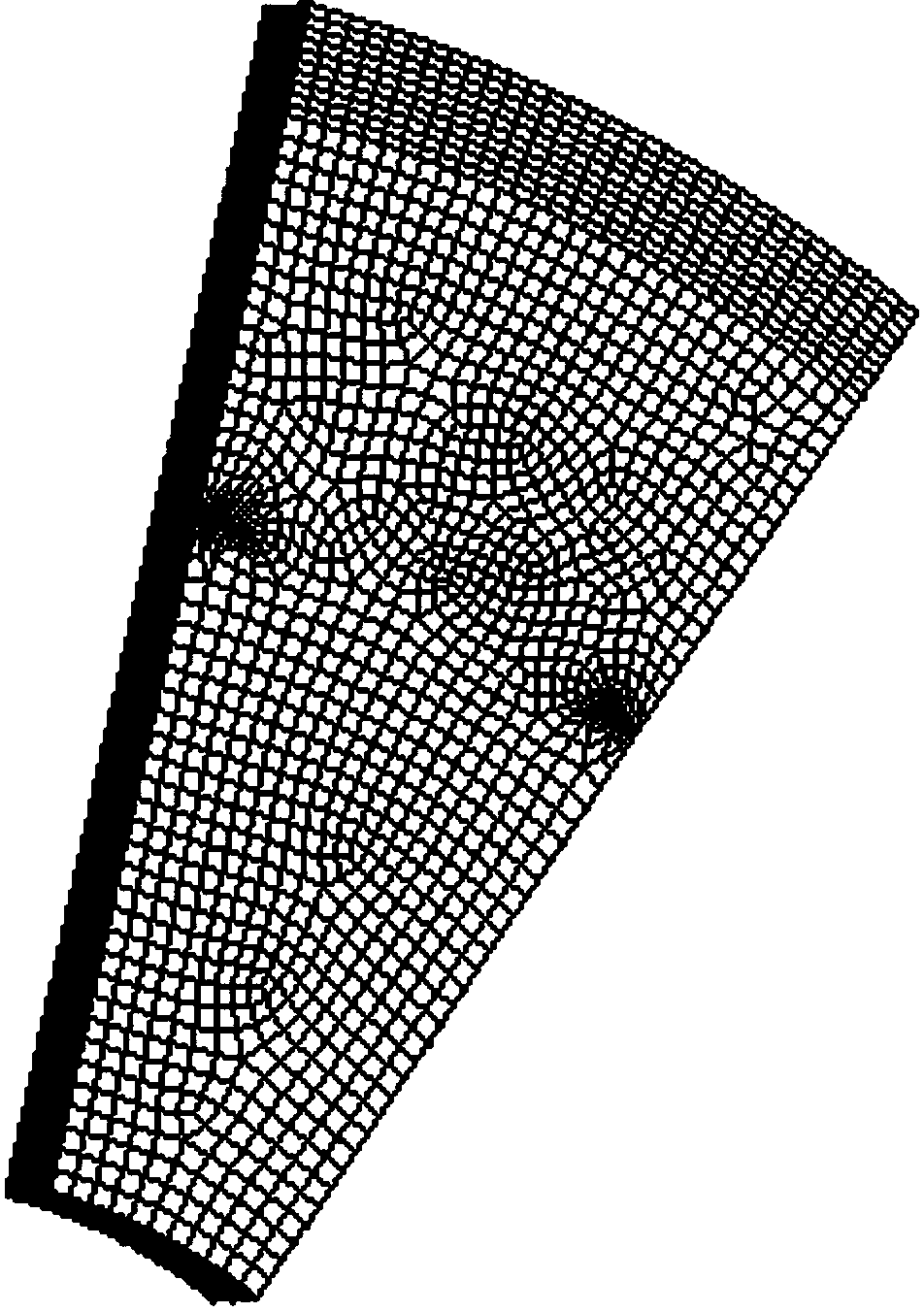

[0014] Refer to attached figure 1 , is a motor rotor structure, which includes a protective cover 1, a magnetic steel 2, a rotor core 3, and a rotating shaft 4. The protective cover 1 is a composite material with a total thickness of 2mm, the first to fourth layers are fiber A, the winding direction is at an angle of 30 degrees to the rotating shaft 4, the thickness of the first to fourth layers is 0.1mm, and the pre-tightening force of each layer is 500N , the fifth to twelfth layers are fiber B, the winding direction is at an angle of 45 degrees to the rotating shaft 4, the thickness is 0.2mm, and the preload force of each layer is 600N. When the motor is running, the protective cover 1 will be subjected to the centrifugal force of the magnetic steel 2 . The entire finite element analysis simulates and analyzes the stress situation of the protective cover 1 during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com