Method for tuning and optimizing parameters of dynamic absorber based on machining process

A technology of dynamic vibration absorber and optimization method, applied in the field of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

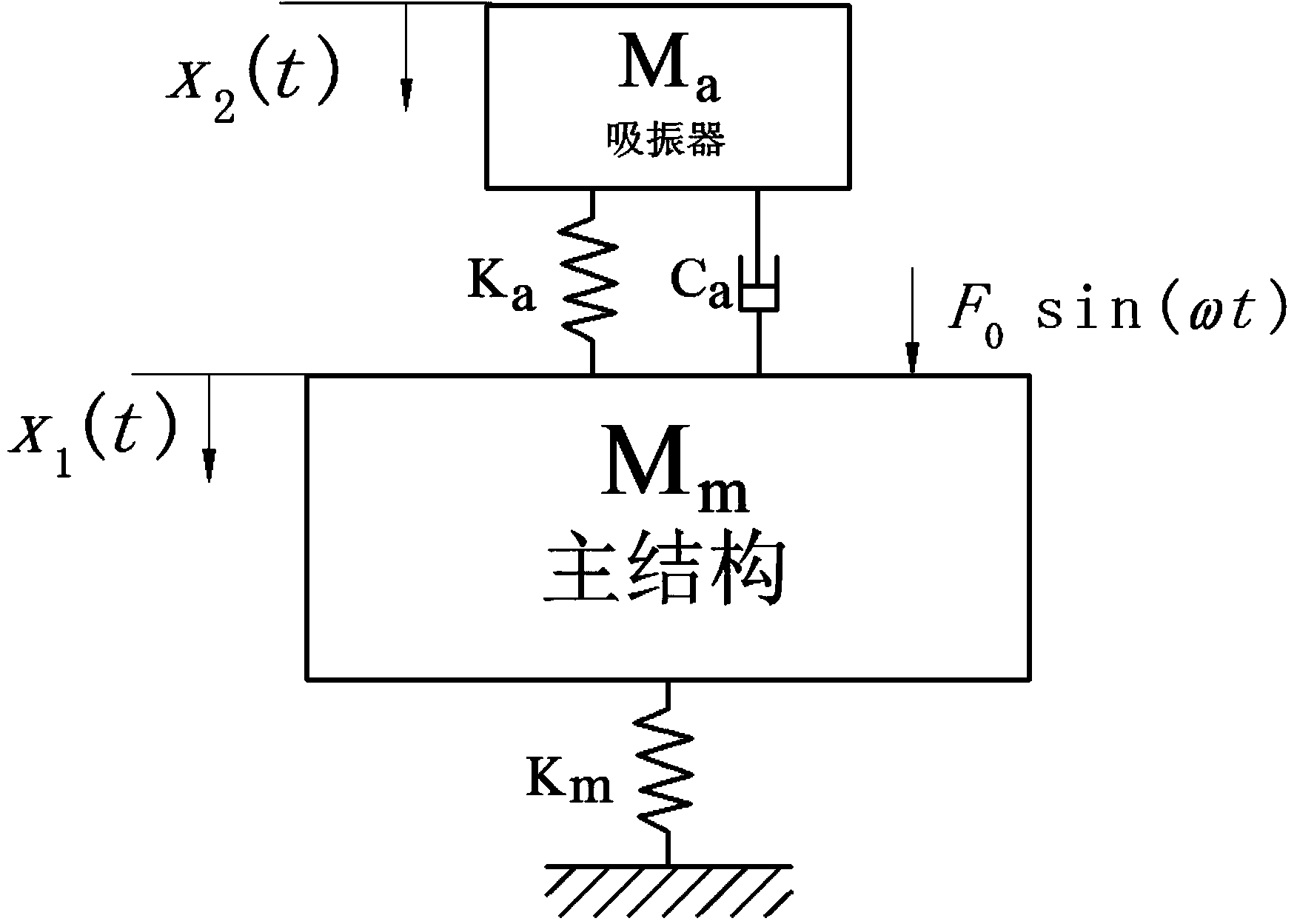

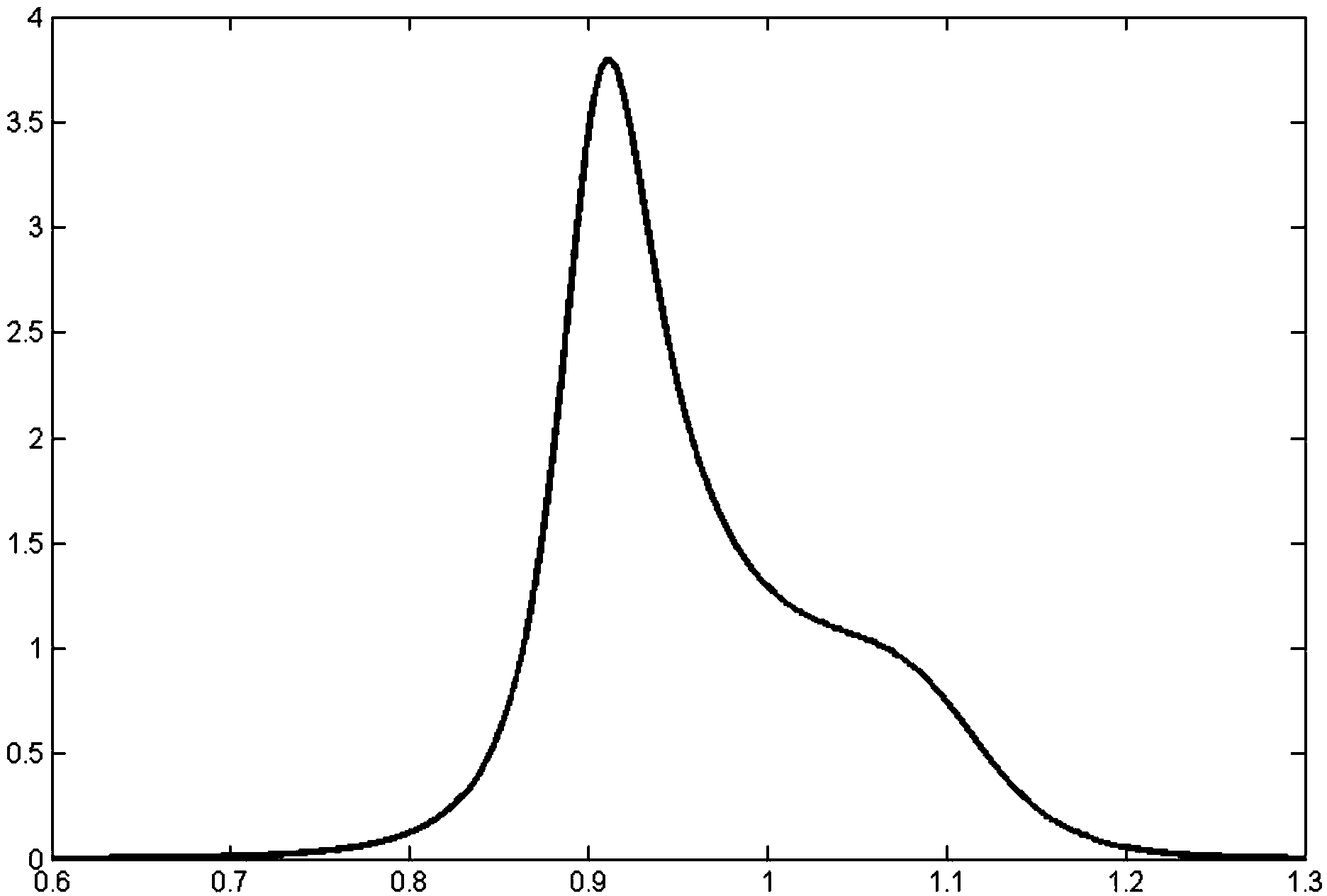

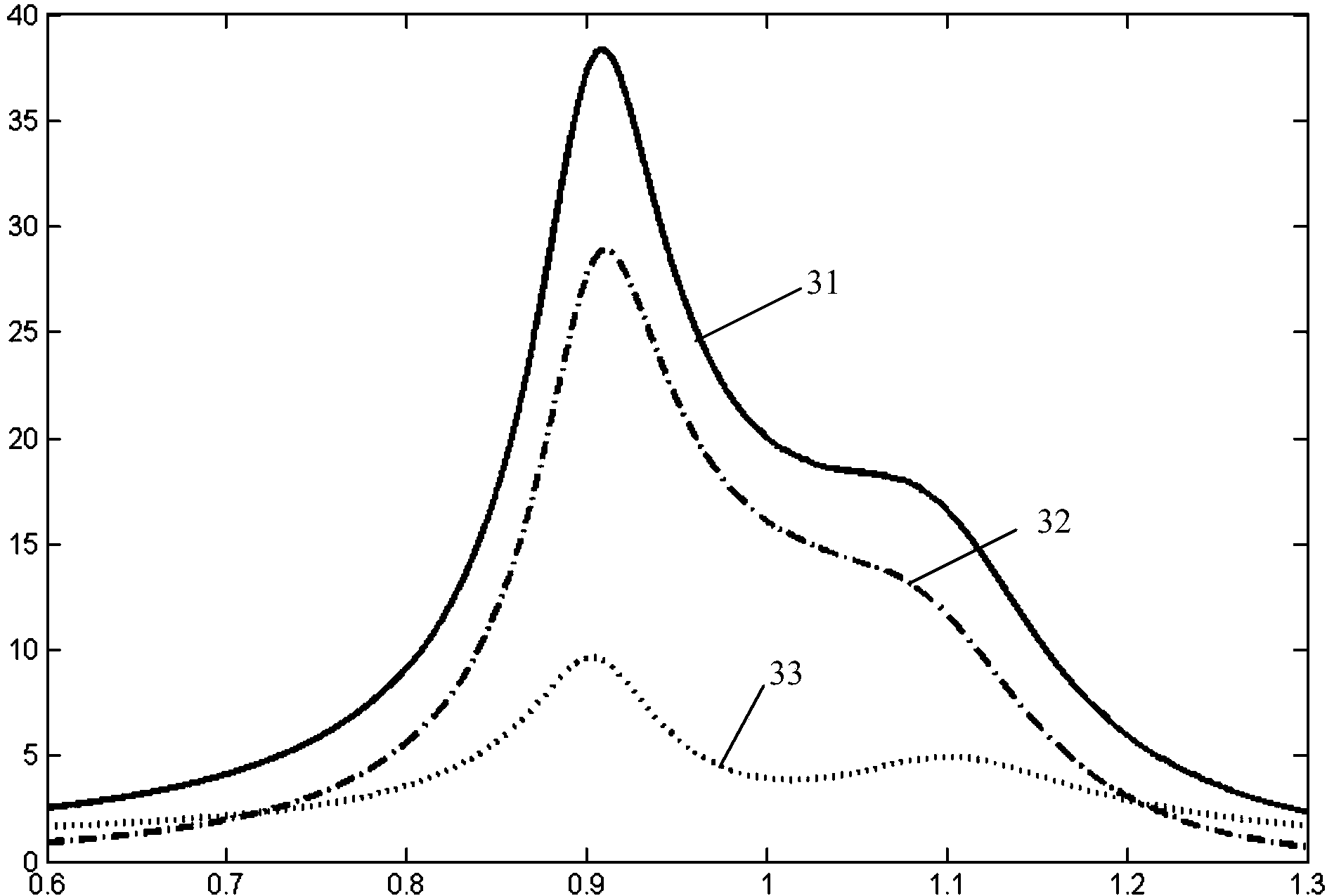

[0086] It can be seen from the formula (7) that the energy consumption ΔW is a function of the excitation frequency ratio g when the structural parameters are determined. When f=1, , when ζ=0.1, ΔW vs. The relationship curve is as figure 2 shown. In order to illustrate the reason for the peak of the curve, draw X 1 , X 2 and ΔX pair curves such as image 3 shown.

[0087] by right figure 2 with image 3 It can be seen from the observation that the energy consumption near the excitation frequency ratio g=0.9 is mainly due to the increase of the main structure, the dynamic vibration absorber and their relative amplitude, which is contradictory to the limited design space of the dynamic vibration absorber. In order to find satisfactory parameters of the shock absorber, their influence on the energy absorbed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com