Piece goods blemish detecting method based on morphological analysis

A technology based on morphology and defect detection, applied in image analysis, image data processing, instruments, etc., can solve the problems of large amount of calculation and difficult to guarantee the accuracy of information, so as to improve the calculation speed, clear structure and accurate processing results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

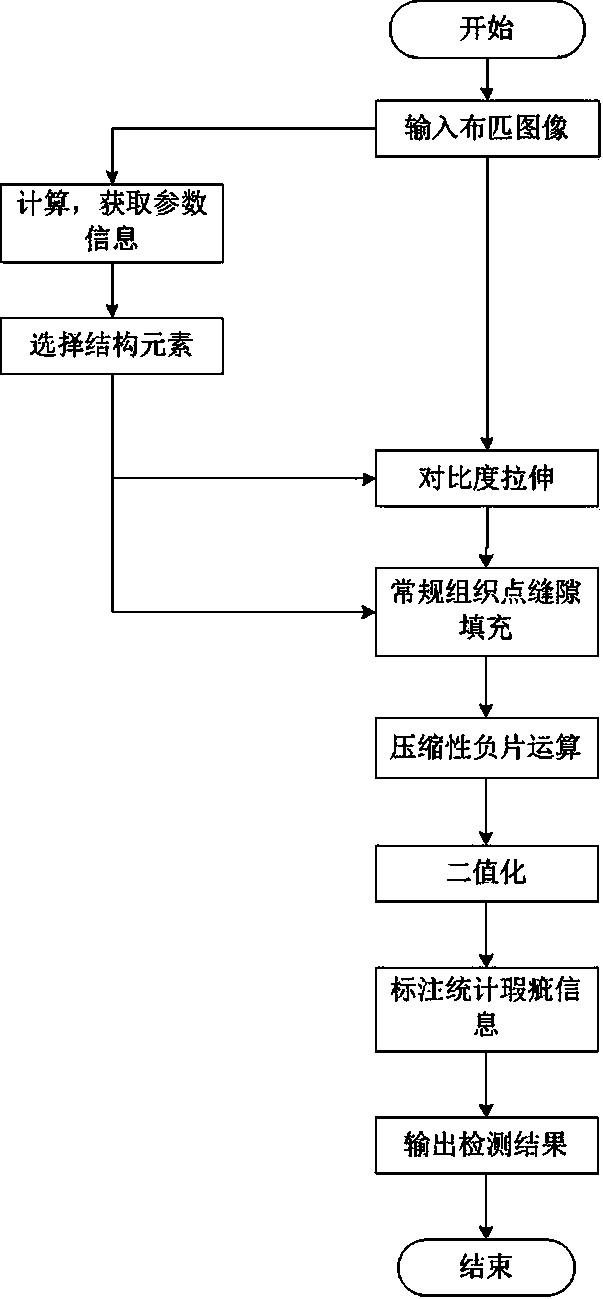

[0026] Embodiment one: see figure 1 Shown is the flow chart of the research on cloth defect detection method based on morphological analysis. Firstly, the structural elements of the collected images are calculated, the contrast is enhanced by morphological methods, the closing operation is used to fill the gaps of tissue points, the compressive negative film operation is performed, binarization is performed, and relevant information is output by statistically marking defects.

[0027] Such as Figure 2 to Figure 6 is a typical defect image collected by the present invention, as follows Figure 4 As an example, the detection algorithm is described in detail:

[0028] 1. Calculate the size of the structural element

[0029] First, calculate the distance between adjacent tissue points of the collected cloth image. When the cloth image is large, sample segmentation and collection can be performed on the cloth image. For example, the intercepted length of a=500 and width of b=20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com