Method for processing LED (Light-Emitting Diode) variable message sign

A processing method and marking technology, which is applied in the processing field of LED variable information signs, can solve problems such as poor uniformity, uneven LED brightness, uneven lens height, etc., and achieve the effect of solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

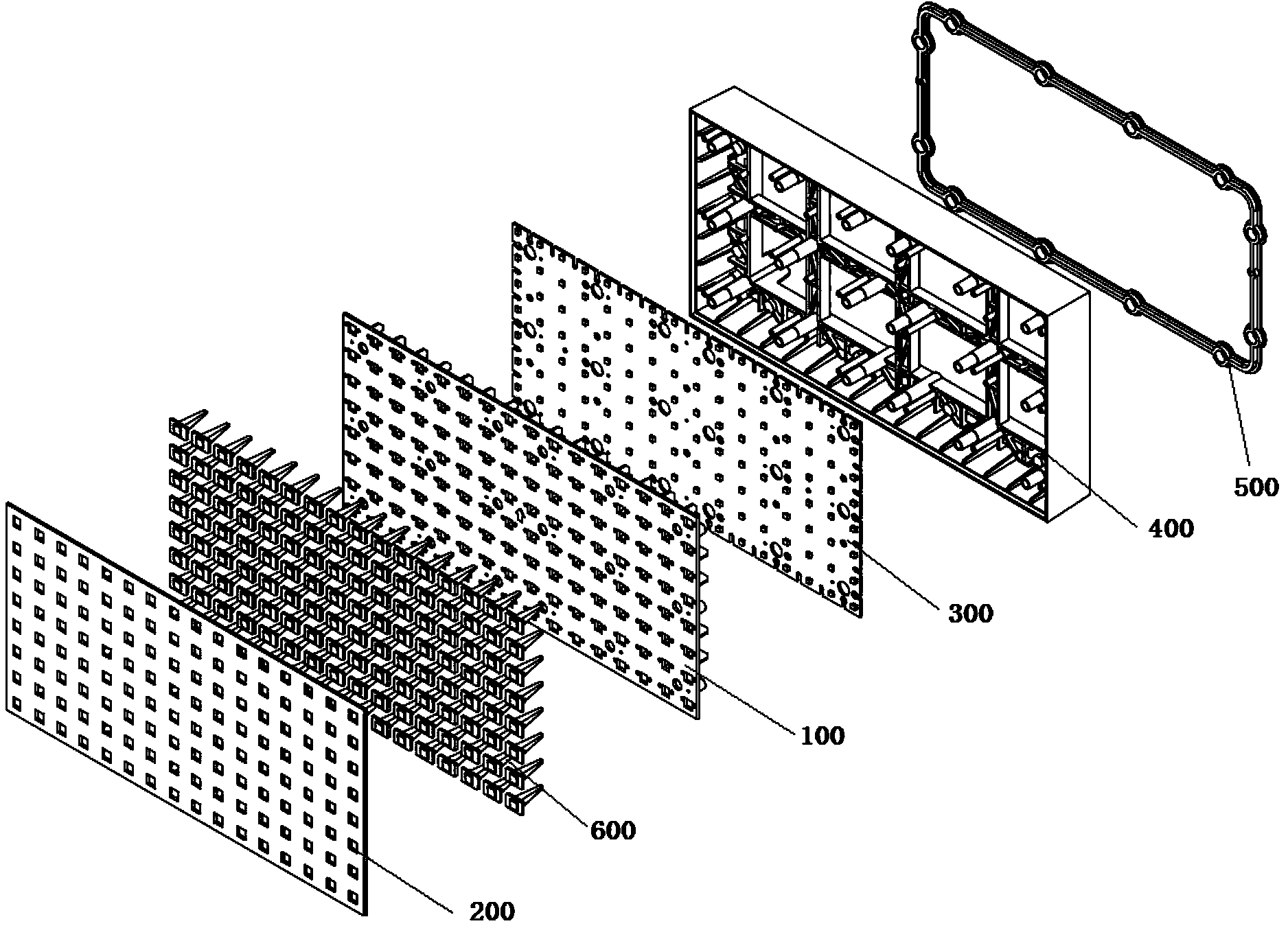

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

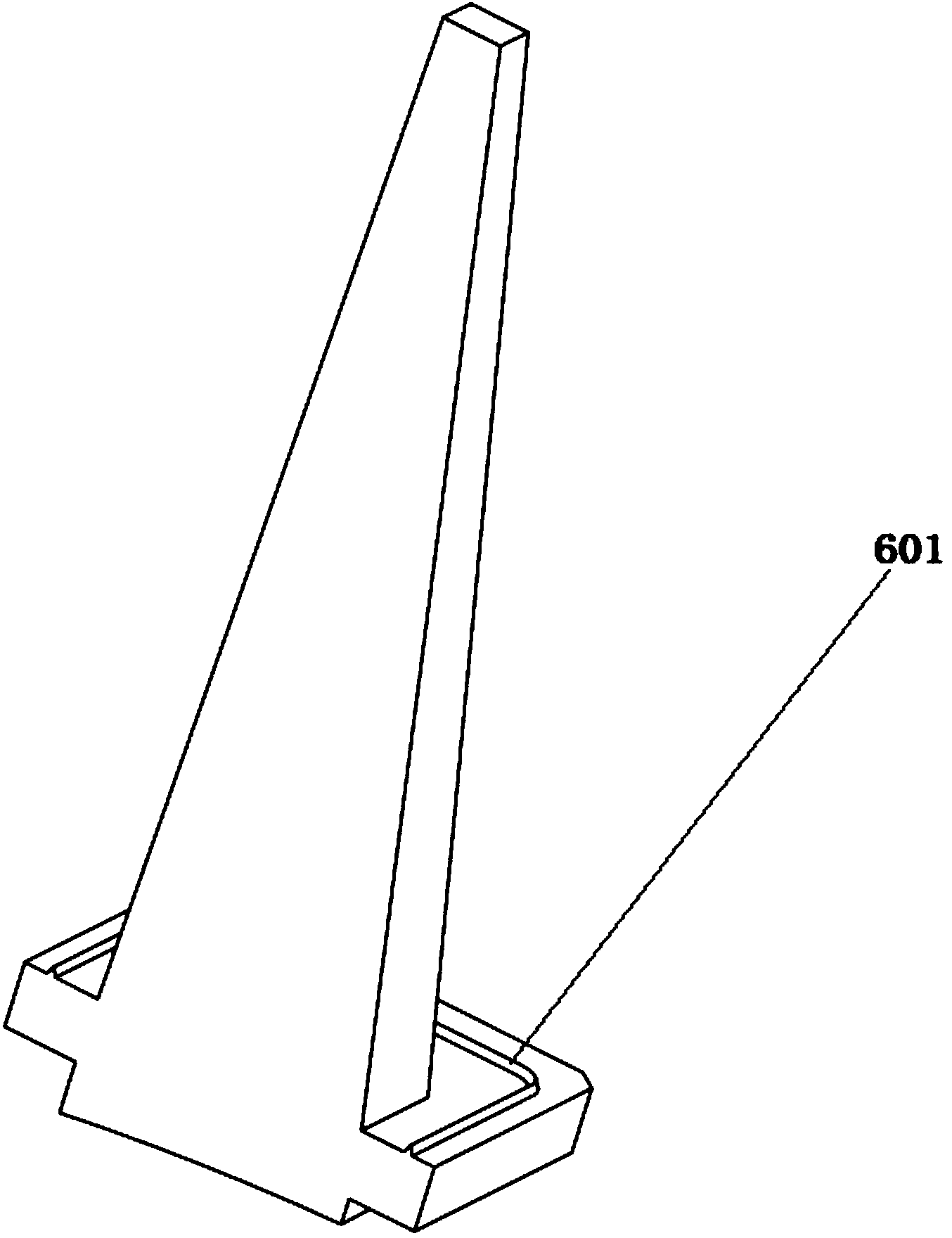

[0030] Step 1: Add ultrasonic lines to the mounting surface of the lens.

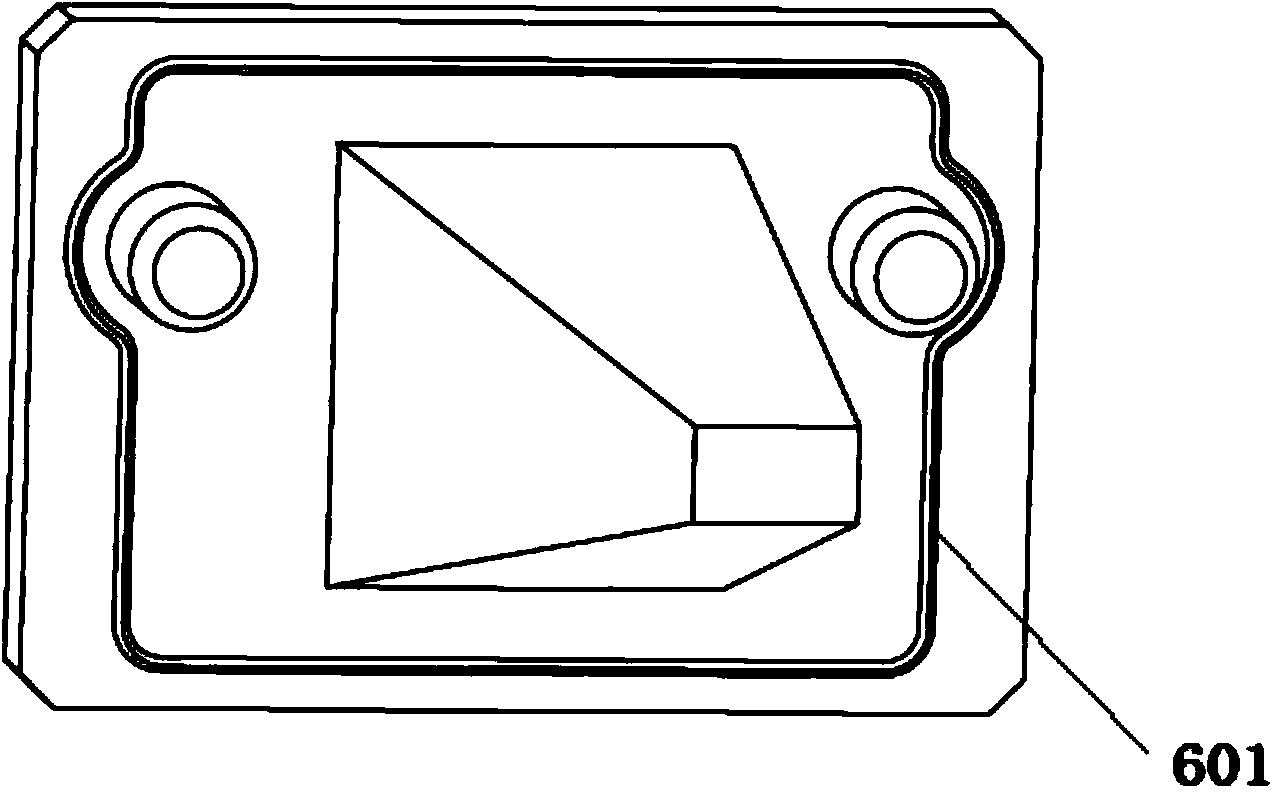

[0031] The section of the ultrasonic wire needs to be designed as an isosceles triangle. See picture. Welding is uniform, starting from the tip of the isosceles triangle, the amount of glue at both ends of the isosceles triangle is equal, the flatness after welding can be guaranteed, and the uniformity and upright consistency of the lens after welding to the lens holder is guaranteed.

[0032] Step 2: Design and produce the metal fixed base mold for ultrasonic welding for the lens holder.

[0033] The shape of the bottom mold adopts a hollow close fit design, so that the lens holder and the lens can be embedded in the bottom mold more closely. The contact distance between the lens holder and the bottom mold should be kept between 0.05mm and 0.08mm. If it exceeds, it will affect the uniformity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com