Energy-saving-type multi-contact-set direct-current contactor

A DC contactor and multi-contact technology, which is applied in the direction of relays, relays using electrodynamic effects, electrical components, etc., can solve the problem of scarcity of multi-contact DC contactor products, inability to use three-phase permanent magnet motor circuits, and heat generation Fire hazards and other issues, to reduce fire hazards, reduce contact resistance, and save power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with the accompanying drawings and simple embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

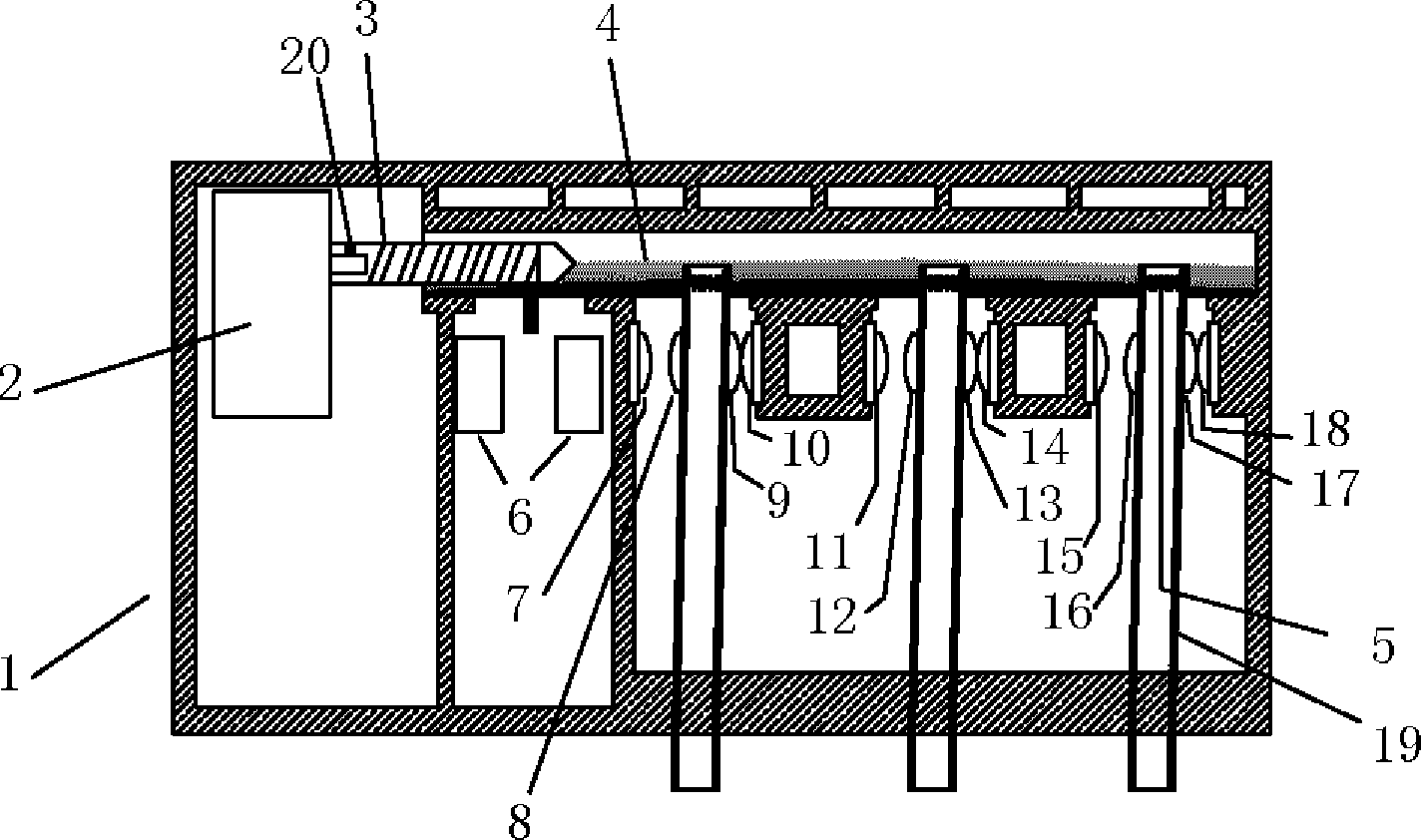

[0012] Such as figure 1 As shown, an energy-saving multi-contact group DC contactor is composed of an injection-molded insulating casing 1, a driving motor 2, and multiple sets of static contacts and moving contacts. The driving motor 2 installed inside the injection-molding insulating casing 1 passes through Forward rotation or reverse rotation drives the screw 3 to rotate, thereby driving the push rod 4 to produce a mechanical movement of pushing or pulling, thereby driving the moving contact group on the moving contact arm 19, that is, the moving contact 8, the moving contact 9, The movable contact 12, the movable contact 13, the movable contact 16, and the movable contact 17 move left and right between the static contact groups at the same time to achieve the purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com