Variable-speed hub motor

A variable speed hub and motor shaft technology, applied in the field of wheels, can solve the problems of easy deformation of the support shaft, threat to driving safety, and lack of heat dissipation, so as to achieve the effects of not easy to break and deform, simple and direct adjustment, and improve power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

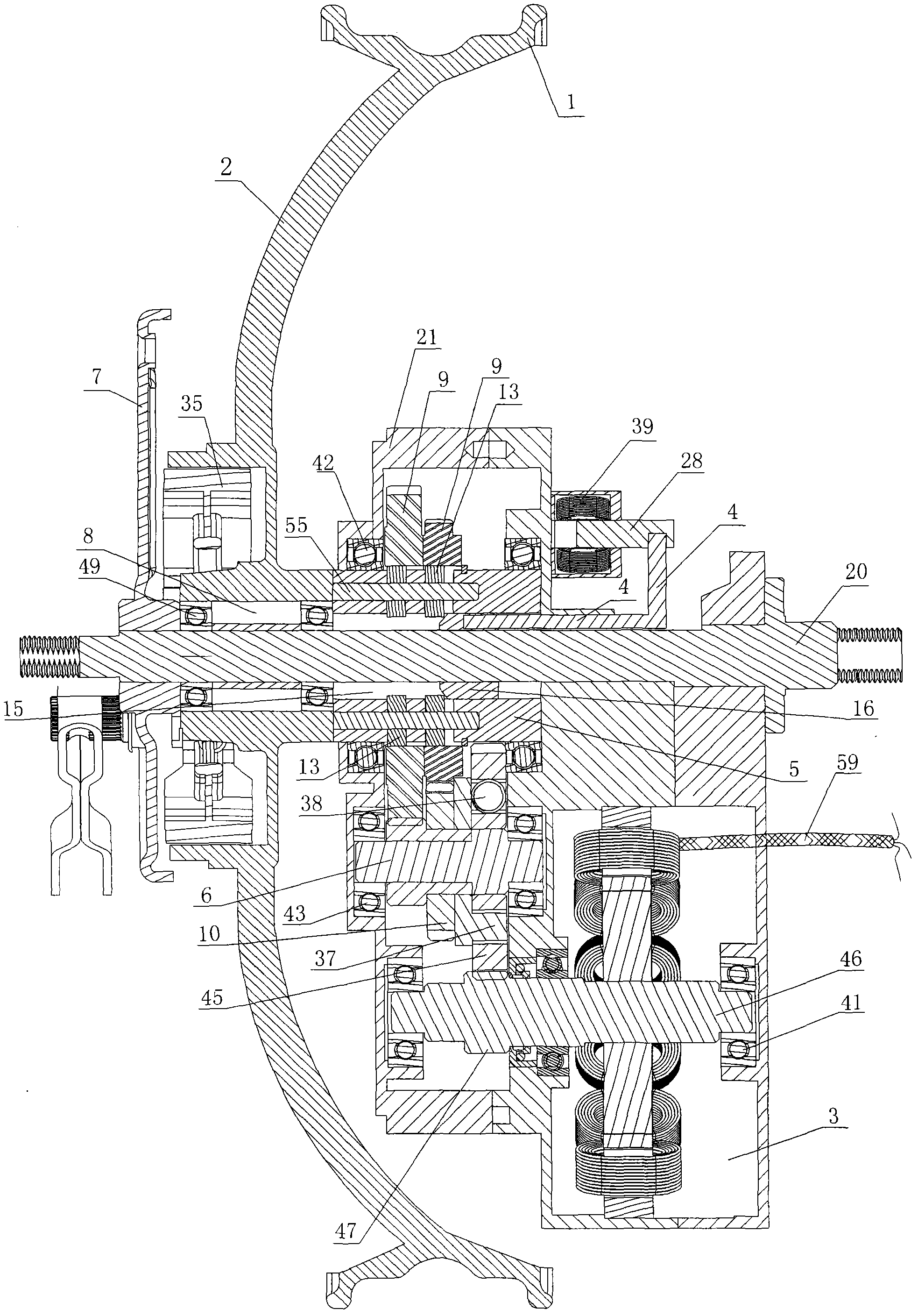

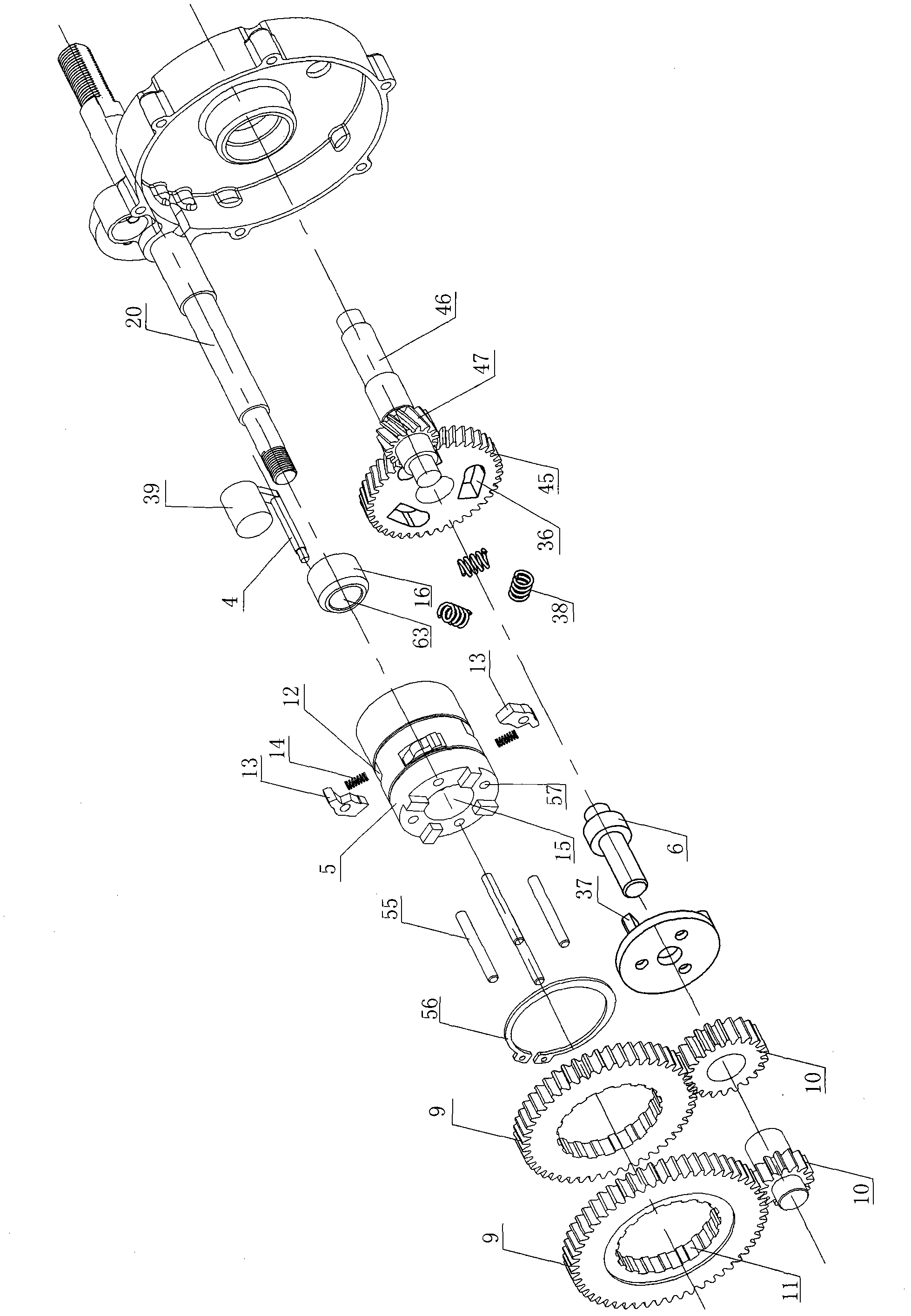

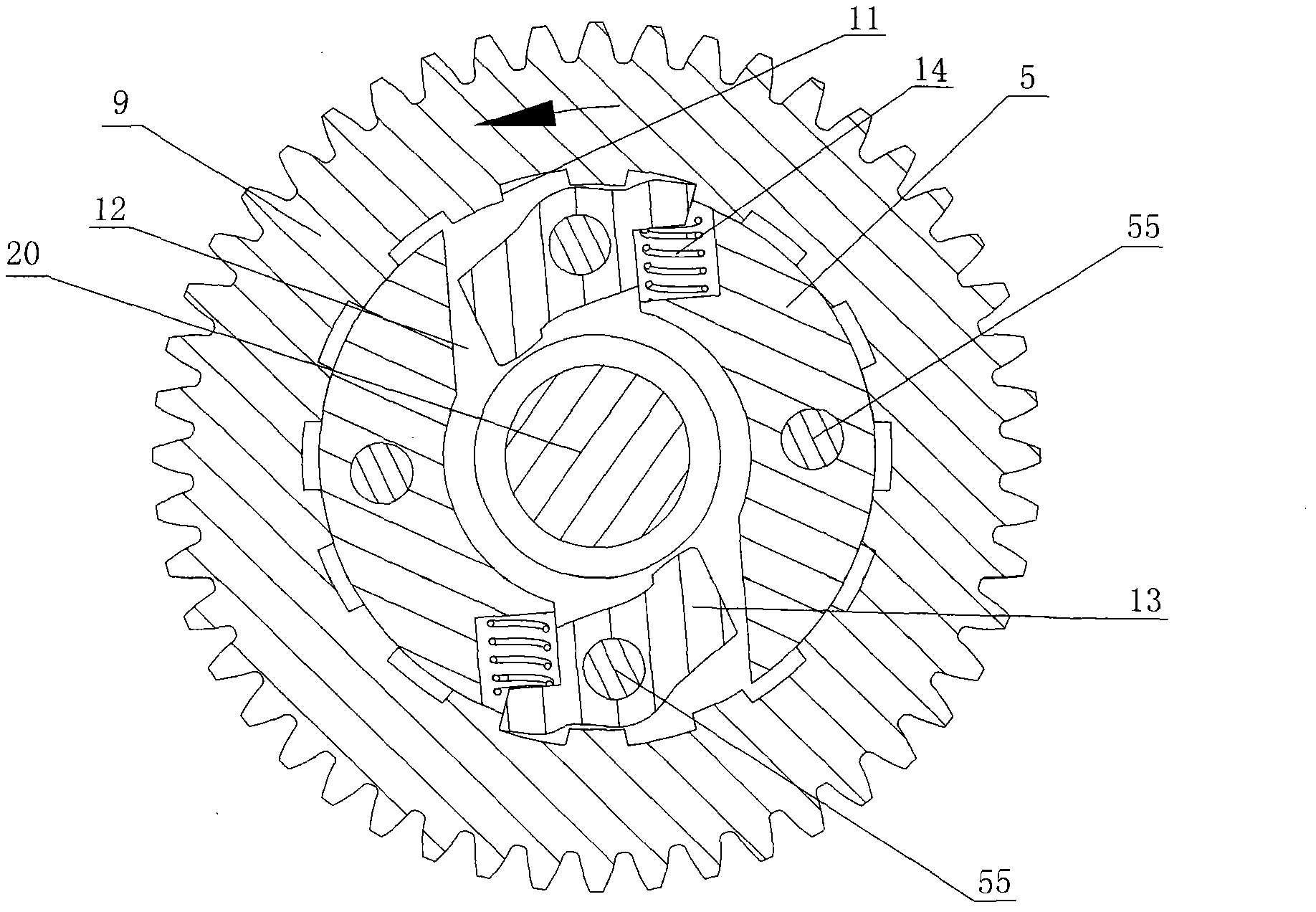

[0022] Such as figure 1 As shown, the variable speed hub motor includes a hub ring 1 connected to an end face 2 connected to a hollow output shaft 5 , and a solid support shaft 20 is provided in the shaft hole 15 of the hollow output shaft 5 .

[0023] The motor 3 is fixed on the support shaft 20, and the power cord 59 of the motor 3 protrudes from the motor casing. The motor 3 is fixed on the side of the support shaft 20, and the adjusting rod 4 and the axis line of the support shaft 20 are staggered and arranged in parallel. The motor 3 is provided with a motor shaft bearing 41 , and the motor shaft 46 is arranged in the motor shaft bearing 41 . The outer end of the motor shaft 46 is provided with a motor shaft gear 47 .

[0024] The motor 3 is fixed with a gearbox housing 21, the housing 21 is provided with a hollow output shaft 5 and an input shaft 6, the support shaft 20 passes through the shaft hole 15, and the hollow output shaft 5 is coaxial It is sleeved on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com