Welding machine control program upgrade system and upgrade method

A technology for controlling programs and welding machines, applied in transmission systems, electrical components, etc., can solve problems such as poor timeliness, high maintenance costs for welding machine software upgrades, and low efficiency, and achieve the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

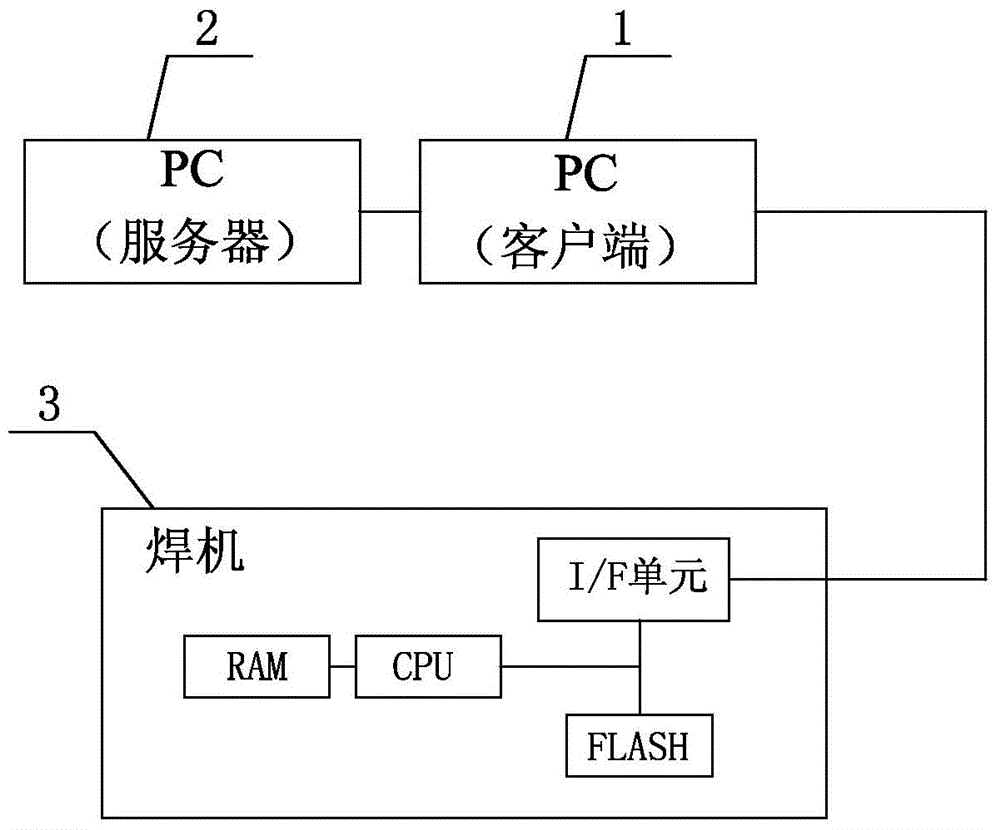

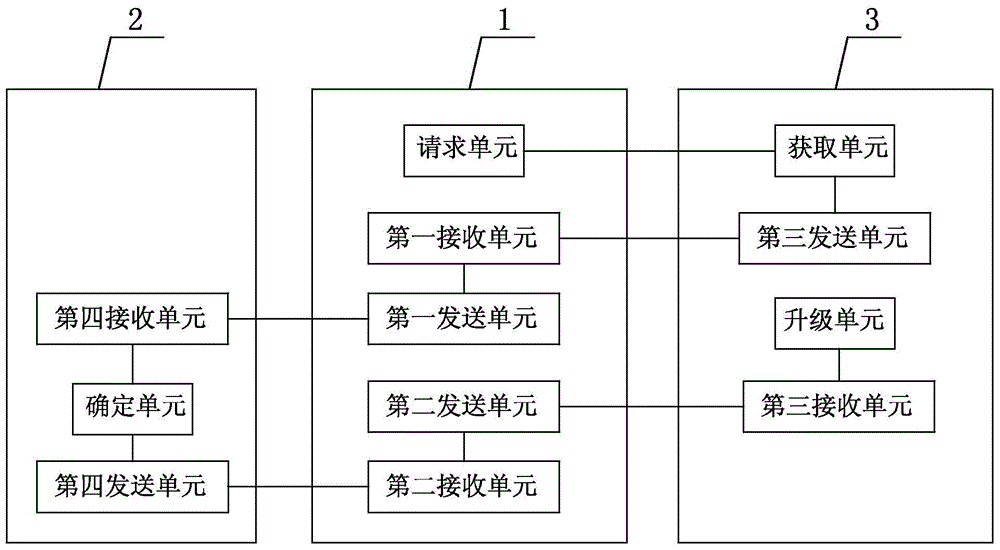

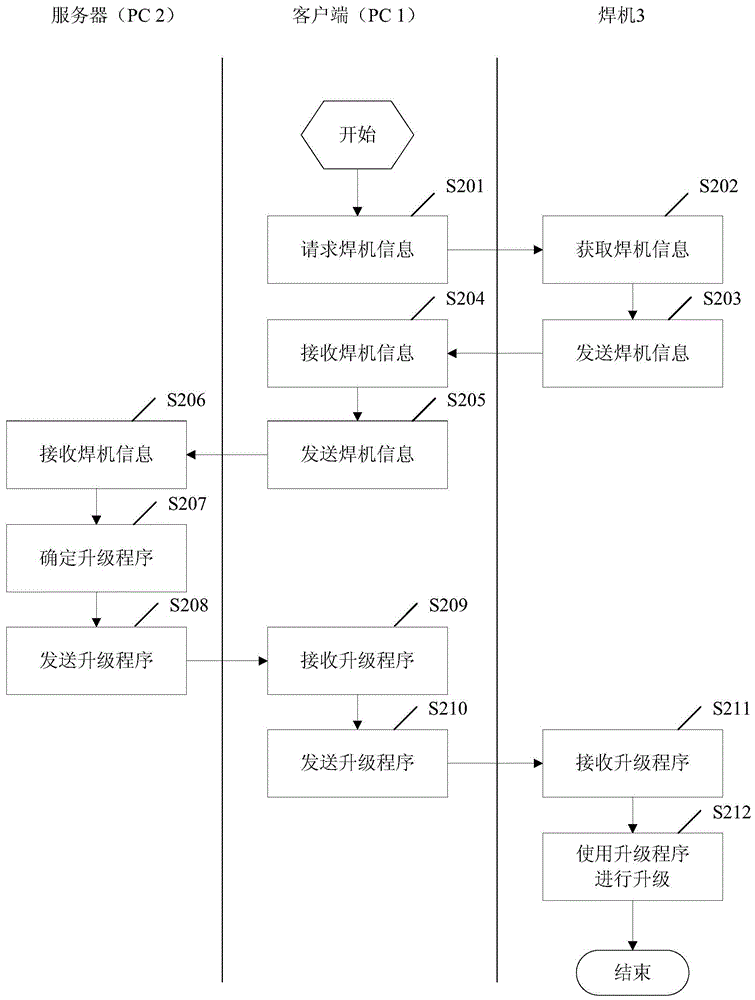

[0024] figure 1 It is a block diagram of the hardware structure of the welding machine control program upgrading system of the first embodiment of the present invention. Such as figure 1 As shown, the welding machine control program upgrading system of the present invention includes a client PC1, a server PC2 and a welding machine 3. PC1 and PC2 are connected through a network so as to be able to communicate with each other. PC1 and welding machine 3 are connected so as to be able to communicate with each other. CPU, RAM, FLASH and interface (I / F) units (such as wired network interface, wireless network interface, USB interface, etc.) are provided in the welding machine 3 . The CPU is used for overall control over the upgrade of the welder. RAM is the working area of the CPU, and FLASH (flash memory) is used to store programs and data executed by the CPU. The I / F unit is used for the connection between the welding machine 3 and the PC1. Although in the first embodiment...

Embodiment 2

[0035] Combine below Figure 4 and Figure 5 A second embodiment of the present invention is described.

[0036] In the second embodiment, the hardware configuration of the present invention is the same as that of the first embodiment, so the description will not be repeated.

[0037] In the second embodiment, the software structure of the present invention ( Figure 4 ) with that of the first embodiment ( figure 2 ) are basically the same, so the description will not be repeated for the same parts. Only the differences between the second embodiment and the first embodiment are described below.

[0038] The difference between the second embodiment and the first embodiment is that a verification unit (such as Figure 4 shown), is used to verify the welding machine information, and the determination unit determines the upgrade program corresponding to the welding machine according to the verified welding machine information.

[0039] Figure 5 It is a flow chart of upgra...

Embodiment 3

[0042] The following combination Figure 6 and Figure 7 A third embodiment of the present invention is described.

[0043] In the third embodiment, the hardware configuration of the present invention is the same as that of the first embodiment, so the description will not be repeated.

[0044] In the third embodiment, the software structure of the present invention ( Figure 6 ) with that of the first embodiment ( figure 2 ) are basically the same, so the description will not be repeated for the same parts. Only the differences between the third embodiment and the first embodiment are described below.

[0045] The difference between the third embodiment and the first embodiment is that an encryption unit (such as Figure 6 shown), is used to encrypt the determined upgrade program by using the welding machine information, and a decryption unit (such as Figure 6 shown), used to decrypt the encrypted upgrade program according to the welder information.

[0046] Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com