Synergistic H2S/mercaptan scavengers using glyoxal

A kind of technology of dialdehyde and thiol, applied in the field of removing H2S and/or thiol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

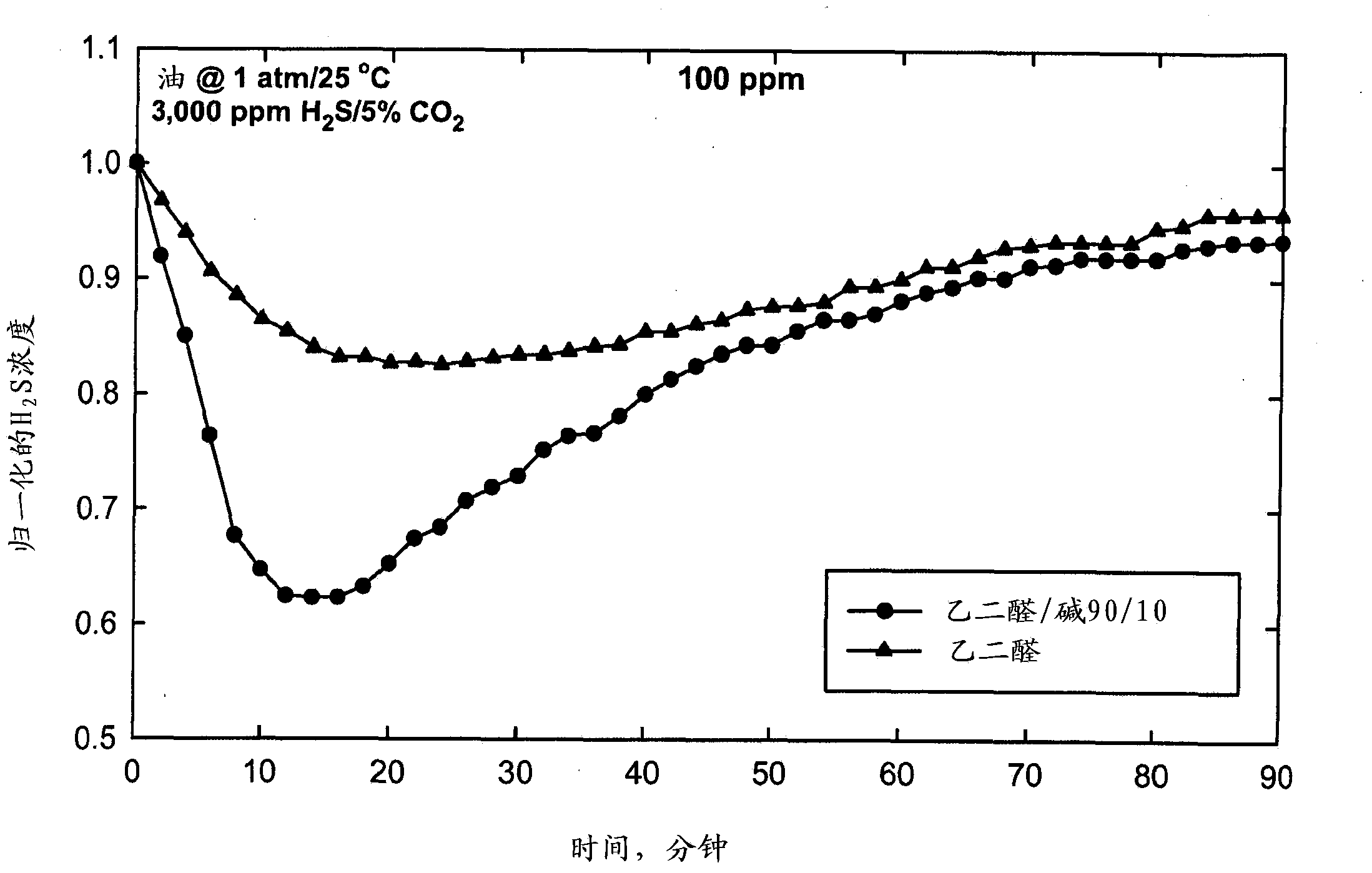

[0038] Such as figure 1 as shown, figure 1 It is used to remove H from oil under the conditions of 1 atmospheric pressure (0.1MPa) and 25°C 2 Normalization H of S as a function of time 2 Graph of S concentration where the oil contains 3000ppm H 2 S and 5% CO 2 . The curve (triangle) for glyoxal (40% in water) alone shows that at about 18 minutes H 2 The amount of S decreased to the lowest level and then gradually increased with the consumption of glyoxal. The curve (dots) of glyoxal and alkali (KOH) in a weight ratio of 90 / 10 (total 100 ppm) (glyoxal in 36% water) shows H 2 S decreased more and faster with a minimum slightly above 0.6, which shows that the presence of H 2 S is reduced even more. In addition, even after treatment with a composition as described herein, the presence of H 2 S gradually increased, but did not reach the levels obtained with glyoxal alone over a period of 90 minutes.

Embodiment 2

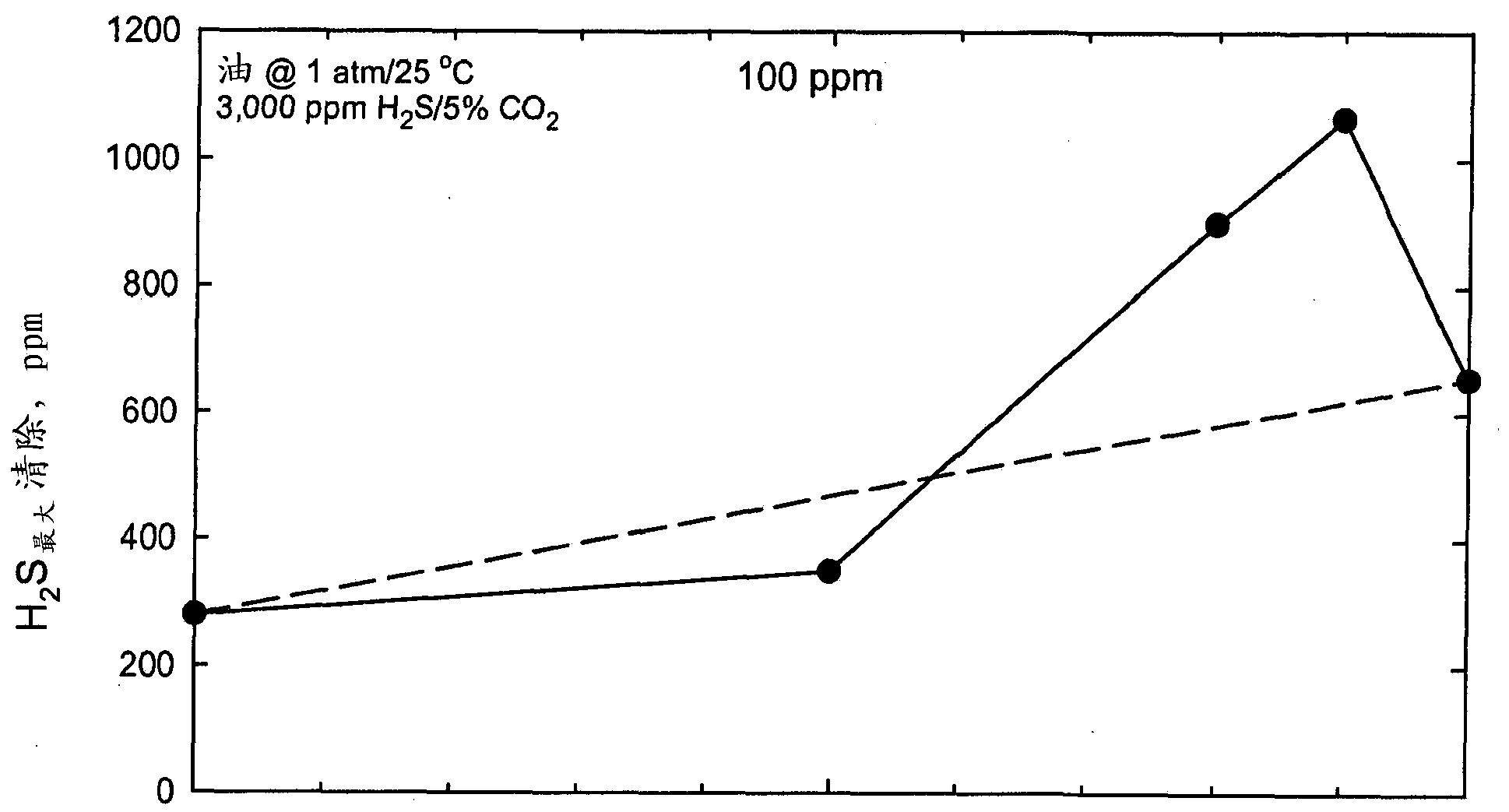

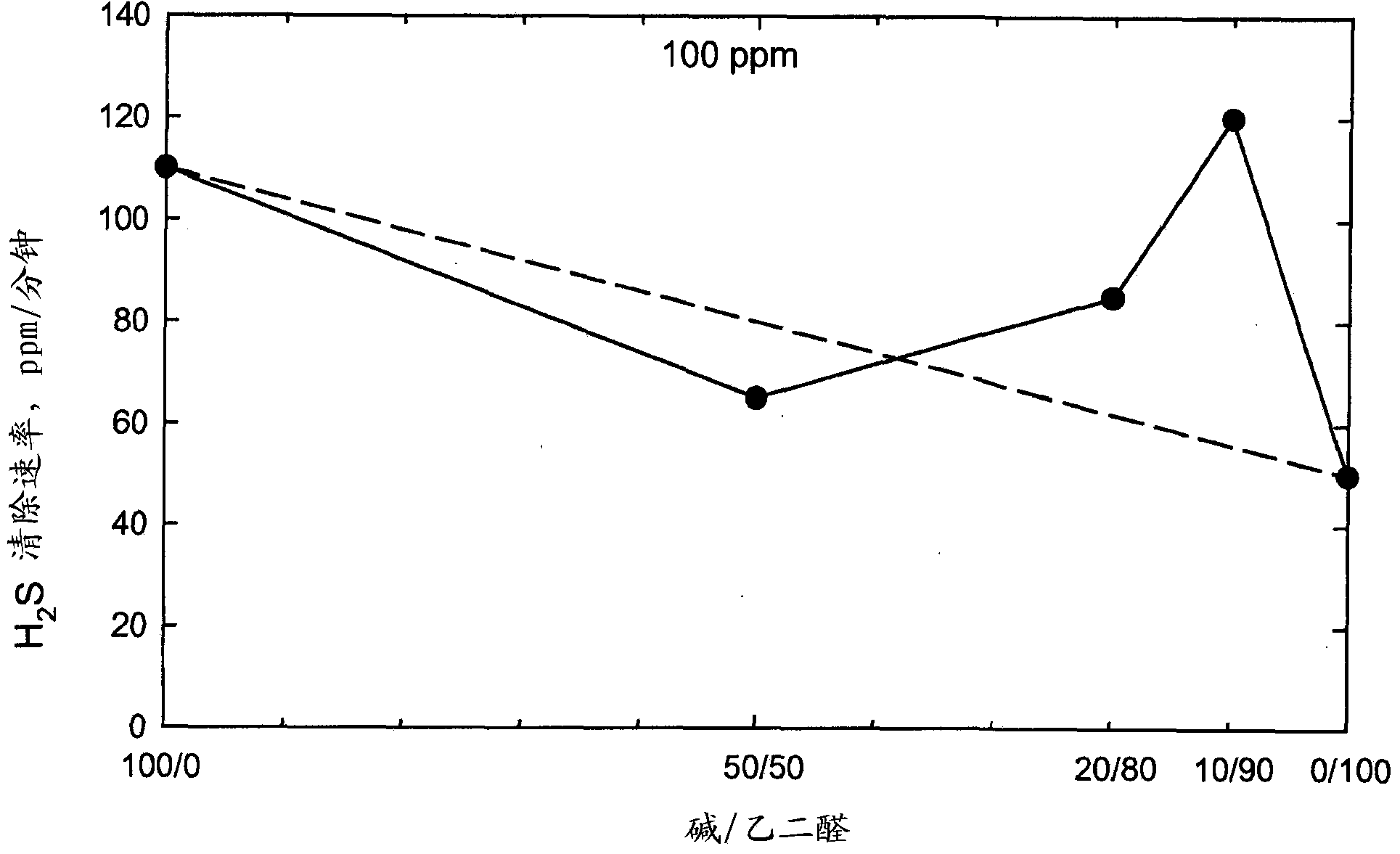

[0040] Such as figure 2 as shown, figure 2 is shown as a function of various weight ratios of base (KOH) / glyoxal (100 ppm total each time, where glyoxal is still in a 40% by weight aqueous solution) at 1 atmosphere (0.1 MPa) and 25°C h 2 Graph of S absorption test results showing the greatest reduction in hydrogen sulfide where the oil contained 3000 ppm H 2 S and 5% CO 2 , and express the cleared H in ppm 2 S. It can be seen that the best performance is obtained when the weight ratio is 10 / 90. image 3 Displays H in ppm / min under the same conditions 2 S Clearance rate. It can be clearly seen that when alkali / glyoxal weight ratio is 10 / 90, compared with only using alkali ( figure 2 with image 3 to the left of ) and using only glyoxal ( figure 2 with image 3 with an unexpected clear H 2 The peak of S ( figure 2 ) and clearance rate ( image 3 ). The dashed lines in both figures represent the expected smooth change from base alone to glyoxal alone (additive...

Embodiment 3

[0042] Such as Figure 4 as shown, Figure 4 is shown as nitrogen-free surfactant (ethoxylated C12 alcohol) / glyoxal at 1 atmosphere (0.1 MPa) and 25°C in various weight ratios (total of 100 ppm each time, where glyoxal remains H as a function of 40% by weight aqueous solution) 2 Graph of S absorption test results showing substantial absorption where the oil contains 3000 ppm H 2 S and 5% CO 2 , and express the cleared H in ppm 2 S. In this graph, the synergistic effect of including nitrogen-free surfactants in different weight ratios can be seen. Figure 5 Displays H in ppm / min under the same conditions 2 S Clearance rate. It can be clearly seen that the surfactant / glyoxal weight ratio of 20 / 80 has an unexpected H 2 S cleared peak ( Figure 4 ), and unexpected H at a surfactant / glyoxal weight ratio of 10 / 90 2 The peak of S clearance rate ( Figure 5 ). The dashed lines in both figures represent the expected smooth change from using only nitrogen-free surfactants t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com