A kind of temperature-sensing milk bottle and production method

A technology for a temperature-sensing milk bottle and a production method, which can be applied to feeding bottles and other directions, can solve problems such as inability to perceive, and achieve the effects of remarkable progress, simple operation process, and rich decorative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

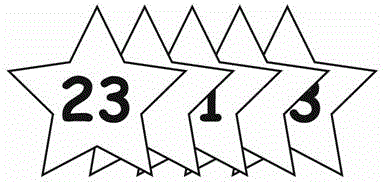

[0049] Digital temperature display: The five-pointed star pattern shows the state of digital change and color change when the temperature range is below 20°C, 23°C, 31°C, 38°C, and 43°C. Adopt the scheme of pasting the prepared floral paper on the feeding bottle.

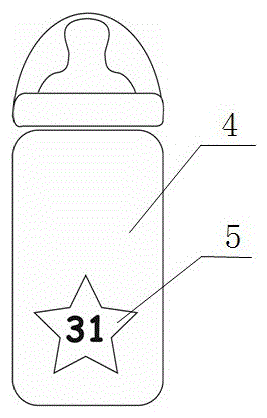

[0050]The temperature-sensitive feeding bottle includes a feeding bottle body 4, and a printing layer 5 is covered on the surface of the bottle body. The printing layer is a temperature-sensitive ink layer, and the temperature-sensitive ink layer includes four groups. One group of temperature-sensitive ink layers includes the bottom layer The pattern layer and the overlay layer above the pattern layer, the pattern layer and the overlay layer of the same group are the same color.

[0051] The pattern layer of the first group of temperature-sensitive ink layers is provided with a pink star-shaped pattern formed by temperature-sensitive microcapsule powder, and there is a blank area of temperature-sensitive microcaps...

Embodiment 2

[0074] Character transformation - the following is the mutual transformation of the characters "spring, summer, autumn, winter" with the change of temperature: at 23°C, the word spring appears and other words disappear; at 38°C, the word summer appears and other words disappear; at 31°C, the word autumn appears Other characters disappear, and winter characters appear at 5°C and other characters disappear. The method of printing on the bottle body of the feeding bottle is adopted, and the feeding bottle is made of plastic material.

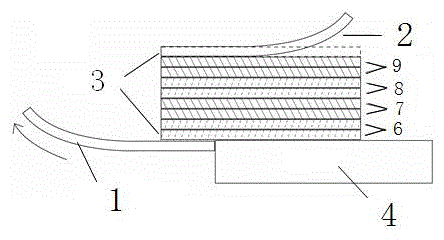

[0075] (1) Print the pattern layer in the first group of temperature-sensitive ink layer 3 on the surface of the bottle body. The pattern layer is provided with the word "Xia" formed by temperature-sensitive microcapsule powder, which is pink when developing color, and the decolorization point 50°C, the pattern layer can be transparent or opaque after reaching the achromatic point;

[0076] (2) Print the cover layer of the first set of temperature...

Embodiment 3

[0086] Pattern transformation——The following is the mutual transformation of patterns at different positions on the same plane as the temperature changes: at 20°C, the "flower" pattern appears and other patterns disappear; at 40°C, the "sun" pattern appears and other patterns disappear; at 30°C, "maple leaf" The patterns appear and other patterns disappear, and the "snowflake" pattern appears and other patterns disappear at 5°C. The temperature-sensitive ink layer includes more than two groups, and the groups are distributed horizontally. Adopt the scheme of pasting the prepared floral paper on the feeding bottle.

[0087] (1) Print the pattern layer in the first group of temperature-sensitive ink layer 3 on the water-transfer small film paper 1. The pattern layer is provided with a "sun" pattern formed by temperature-sensitive microcapsule powder during color development, and the color disappears. The point is 50°C, and the pattern layer can be transparent or opaque after re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com