Full-automatic production line for steel bar truss

A technology for steel bar trusses and production lines, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor intensity, restricting the production volume and automation of steel bar trusses, and low production efficiency, and achieve the effect of improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

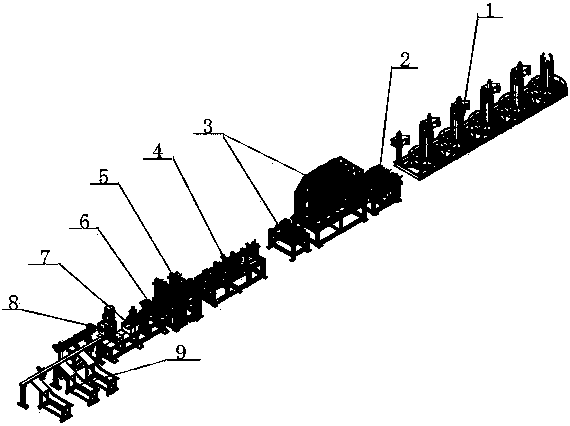

[0032] like figure 1 As shown, the production line of the present invention sequentially includes a wire unwinding device 1, a straightening device 2, a wire storage and terminal straightening device 3, an arching device 4, a welding device 5, a foot bending device 6, a stepping traction device 7, a shearing device Device 8 and automatic collection device 9, the above-mentioned devices are all controlled by PLC;

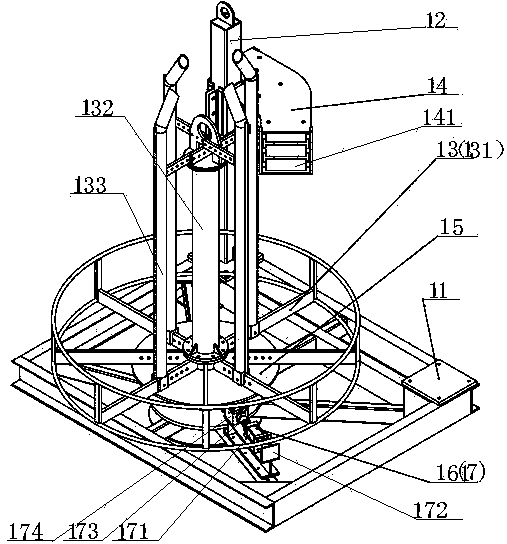

[0033] like figure 2 As shown, five pay-off devices 1 are included, the pay-off device 1 includes a mounting base 11, a lead frame 12 and a pay-off frame 13 are arranged on the mount base 11, a wire device 14 is arranged on the lead frame 12, and the pay-off frame 13 passes through The tray 15 is rotatably connected to the mounting base 11, the mounting base 11 is provided with a constant speed braking device 16, the constant speed braking device 16 is located between the mounting base 11 and the pallet 15, the uniform speed braking device 16 includes a cylinder 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com