Oblique-hole processing platform

A processing table and oblique hole technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of long clamping and positioning time, complex clamping structure, and low precision of oblique holes, and achieve free adjustment of inclination angle Reliable positioning, high fixing strength, fast clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

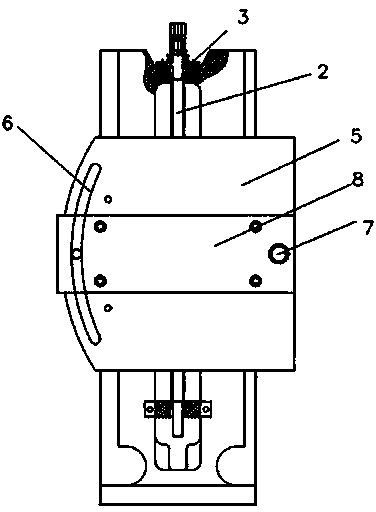

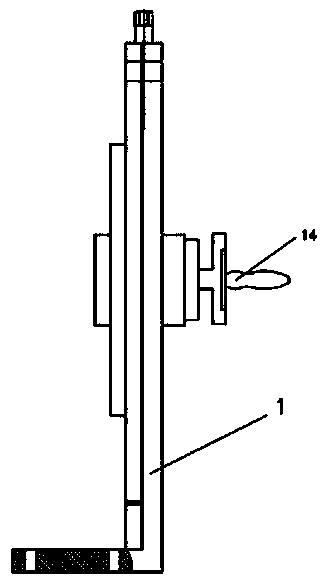

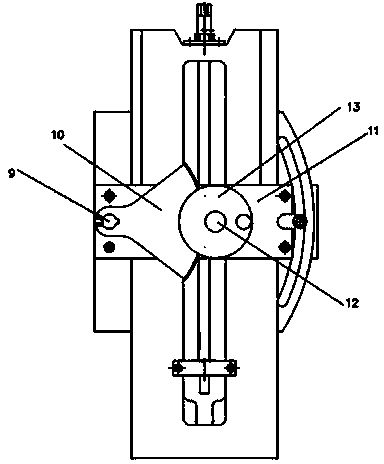

[0015] An oblique hole processing table as shown in the figure includes a vertical plate 1, a screw rod 2, a bearing seat 3, a slider 4, a rotating main board 5, a drilling device mounting plate 8, a horizontal shaft 9, a sector gear 10, and a rotating pair Plate 11 , rotating shaft 12 , first gear 13 , first hand wheel 14 .

[0016] The vertical plate 1 is provided with a screw mounting hole, and the screw 2 is fixed on the vertical plate 1 through the bearing seat 3; the slider 4 is passed on the screw 2 and fixedly connected with the back of the rotating main board 5; the rotating The front end of the main board 5 is provided with an arc-shaped groove 6, and the rear end is provided with a horizontal shaft hole 7; the position corresponding to the mounting plate 8 of the punching device and the horizontal shaft hole 7 is provided with a mounting plate shaft hole, and the horizontal shaft 9 is connected to the sector gear 10 through the shaft hole of the mounting plate and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com