Bean product cutting equipment with mold cleaning function

A technology for cutting equipment and bean products, applied in cleaning methods and utensils, cleaning methods using liquids, metal processing, etc., can solve problems such as high labor intensity and affecting equipment operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

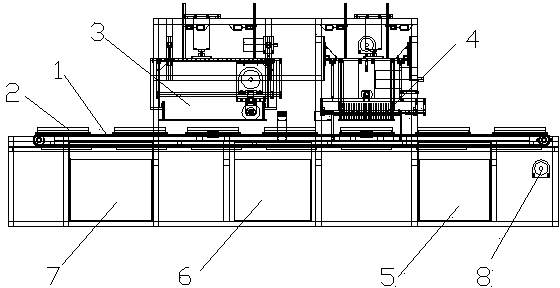

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a bean product cutting equipment with mold disc cleaning includes a conveyor belt 1 and a plurality of mold discs 2 fixed on the conveyor belt 1, the transmission belt 1 is driven by a motor 8, and a transverse cutting device is arranged above the transmission belt 1 Strip equipment 3 and longitudinal strip cutting equipment 4, at least one first clear water tank 5 and the first nozzle communicating with it are arranged below the transmission belt 1, when the transverse strip cutting equipment 3 and the longitudinal strip cutting equipment 4 are paired with the mold plate 2 After the bean products are cut and poured out, the mold plate 2 is rotated to the top of the first clear water tank 5 along with the transmission belt 1, the water pump is started, and the mold plate 2 is cleaned by the first nozzle.

[0014] The bottom of transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com