Cheese dividing and cutting machine

A slitting machine and cheese technology, which is applied in metal processing and other directions, can solve the problem of low cutting efficiency and achieve the effects of preventing deviation, improving work efficiency, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

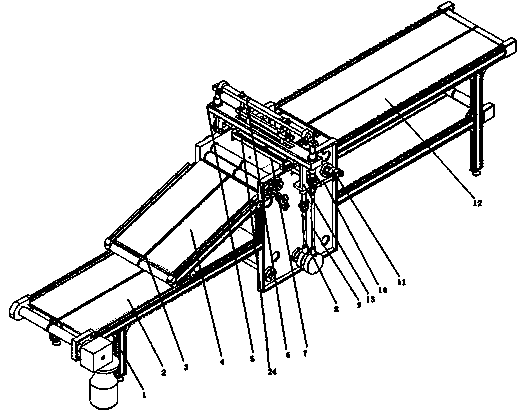

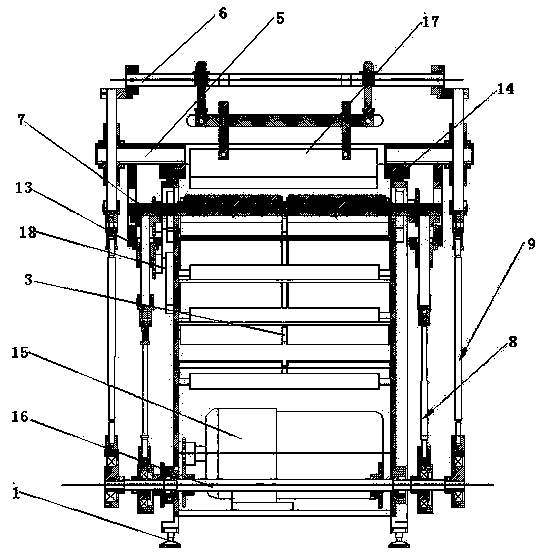

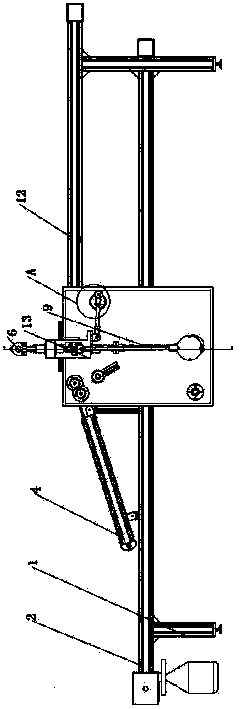

[0018] Depend on figure 1 and image 3 It can be known from the schematic diagram that the cheese slitting machine of the present invention mainly includes a slitting machine frame 1, a conveying mechanism, a cutting mechanism and a synchronizing mechanism.

[0019] The conveying mechanism, the cutting mechanism and the synchronizing mechanism are all arranged on the frame 1 of the slitting machine.

[0020] The conveying mechanism is mainly composed of an upper conveyor belt and a lower conveyor belt 2. The upper conveyor belt includes a horizontally arranged feed conveyor belt 12 and a downwardly inclined discharge conveyor belt 4. The feed conveyor belt 12 and the discharge conveyor belt 4 are in turn Setting, in the middle of the feeding conveyor belt 12 and the 4th-level lower conveyor belt 2 of the discharging conveyor belt, a downwardly protruding stopper 3 is provided, and at the same time, the feeding conveyor belt 12 and the 4th-level lower conveyor belt of the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com