Technology used for desulphurization deamination of coke oven gas

A technology for coke oven gas and deamination, which is applied in the petroleum industry, ammonium sulfate, combustible gas purification, etc., can solve the problems of complex process, unsatisfactory economy, high equipment and operating costs, and achieve the effect of improving economic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

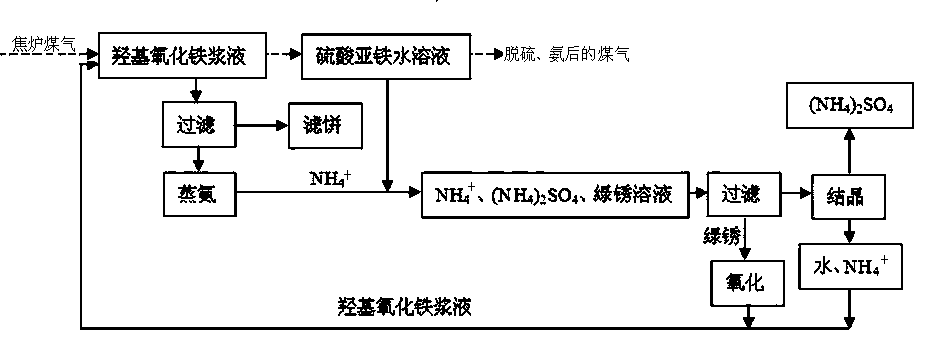

[0039] The flow chart of the process for coke oven gas desulfurization and deammonification described in this embodiment is as follows figure 1 shown, including:

[0040] (1) Pass the coke oven gas from the bottom into the desulfurization tower, the temperature of the desulfurization tower tank is 30°C; the top of the desulfurization tower injects desulfurizer through the nozzle to rinse the coke oven gas, and the desulfurization The agent is an amorphous iron oxyhydroxide slurry, and the concentration of the amorphous iron oxyhydroxide in the slurry is 10wt%.

[0041] (2) The desulfurized coke oven gas in step (1) overflows from the top of the desulfurization tower, and then passes the desulfurized coke oven gas into the ammonia absorption tower, and the coke oven gas and sulfurous acid sulfurous acid sprayed on the top of the ammonia absorption tower The iron solution reacts to remove the ammonia in the coke oven gas, wherein the concentration of the ferrous sulfate solutio...

Embodiment 2

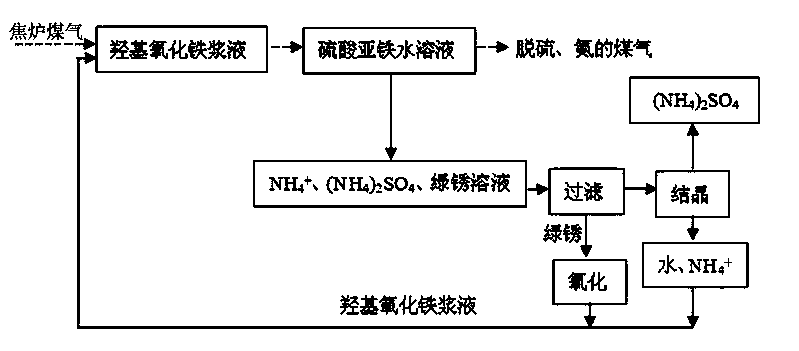

[0045] The flow chart of the process for coke oven gas desulfurization and deammonification described in this embodiment is as follows figure 2 shown, including:

[0046] (1) Pass the coke oven gas from the bottom into the desulfurization tower, the temperature of the desulfurization tower tank is 50°C; the top of the desulfurization tower injects desulfurizer through the nozzle to rinse the coke oven gas, and the desulfurization The agent is an amorphous iron oxyhydroxide slurry, and the concentration of the amorphous iron oxyhydroxide in the slurry is 15wt%.

[0047] (2) The desulfurized coke oven gas in step (1) overflows from the top of the desulfurization tower, and then passes the desulfurized coke oven gas into the ammonia absorption tower, and the coke oven gas and sulfurous acid sulfurous acid sprayed on the top of the ammonia absorption tower The iron solution reacts to remove the ammonia in the coke oven gas, wherein the concentration of the ferrous sulfate solut...

Embodiment 3

[0051] The flow chart of the process for coke oven gas desulfurization and deammonification described in this embodiment is as follows figure 2 shown, including:

[0052] (1) Pass the coke oven gas from the bottom into the desulfurization tower, the temperature of the desulfurization tower tank is 40°C; the top of the desulfurization tower injects desulfurizer through the nozzle to rinse the coke oven gas, and the desulfurization The agent is an amorphous iron oxyhydroxide slurry, and the concentration of iron oxyhydroxide in the slurry is 15wt%.

[0053] (2) The desulfurized coke oven gas in step (1) overflows from the top of the desulfurization tower, and then passes the desulfurized coke oven gas into the ammonia absorption tower, and the coke oven gas and sulfurous acid sulfurous acid sprayed on the top of the ammonia absorption tower The iron solution reacts to remove the ammonia in the coke oven gas, wherein the concentration of the ferrous sulfate solution is 1.0mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com