CL grid plate production method

A production method and grid plate technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as low production efficiency, high labor intensity, and desoldering, so as to improve production efficiency and facilitate The effect of equipment maintenance and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

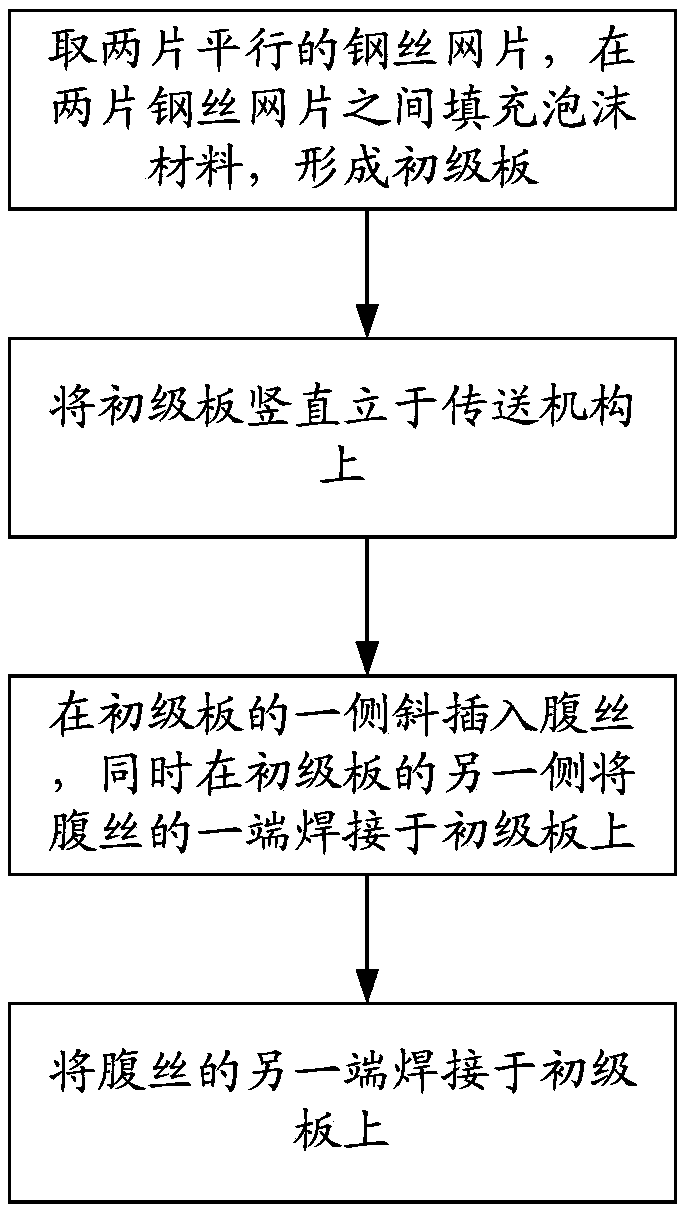

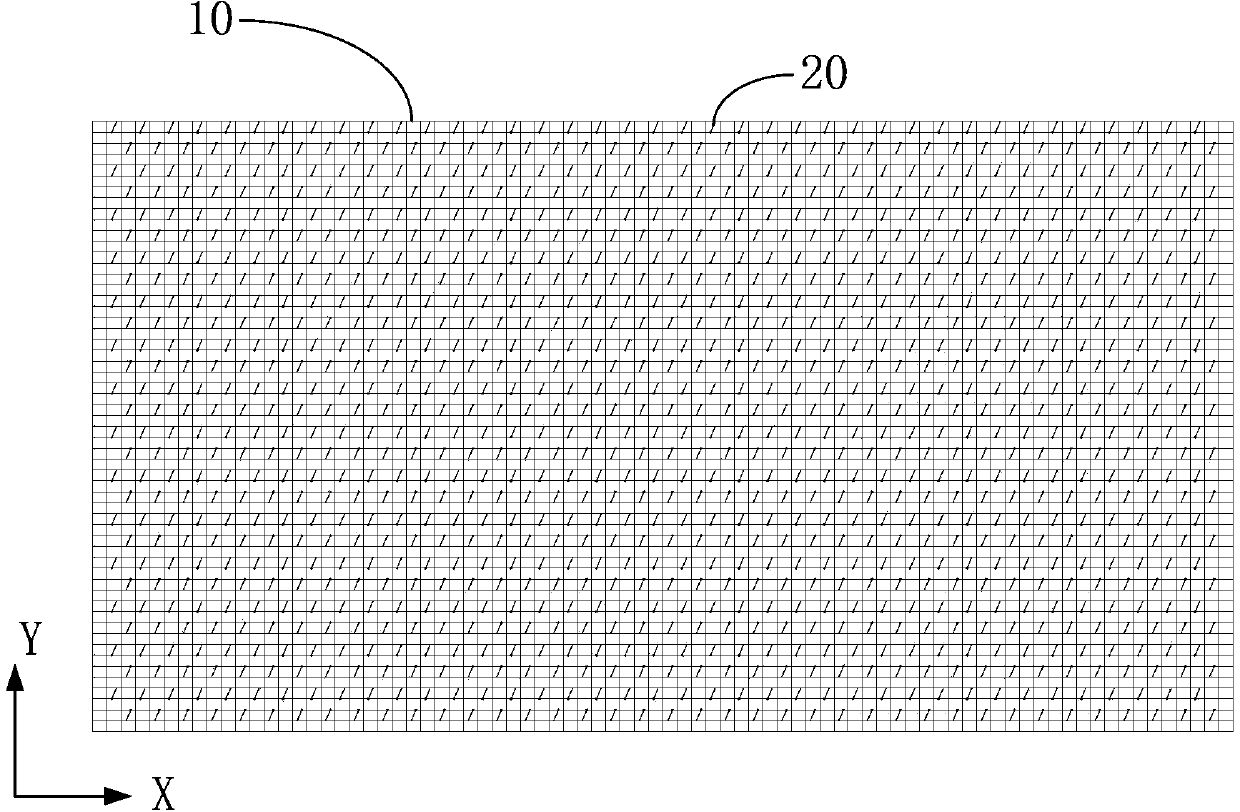

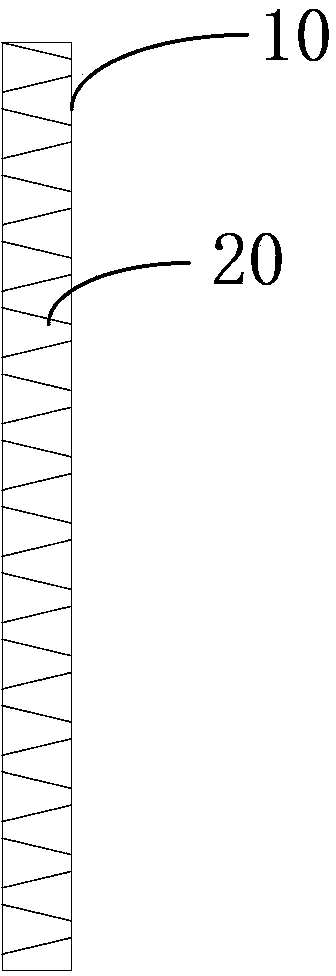

[0028] The production method of CL grid plate provided by the invention, such as Figure 1 to Figure 6 As shown, including S1: take two parallel steel mesh sheets 10, and fill the foam material between the two steel mesh sheets 10. Preferably, in this embodiment, the foam material is flame-retardant polystyrene foam plastic sheet, forming the primary sheet;

[0029] S2: Stand the primary board vertically on the conveying mechanism (not shown in the figure), so that the steel wire mesh 10 and the foam material are aligned on the basis of the bottom edge due to their own gravity, which facilitates the alignment of the steel wire mesh 10 and the foam material. The positioning of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com