Pouring method of concrete pouring device for ultra-high steel pipe concrete column by conduit method

A technology for concrete filled steel tubular columns and concrete, which is applied in the processing of building materials, construction, building structure, etc., can solve problems such as discomfort, and achieve the effects of reducing pipe blockage, small expansion loss, and reliable pouring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

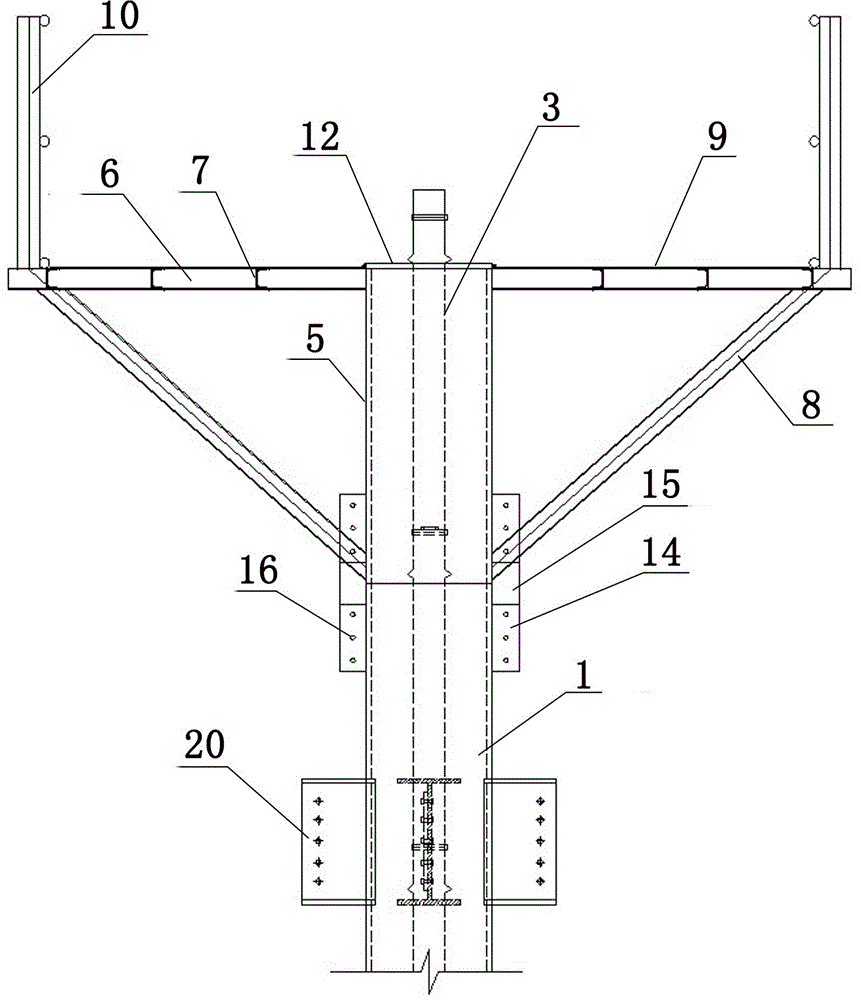

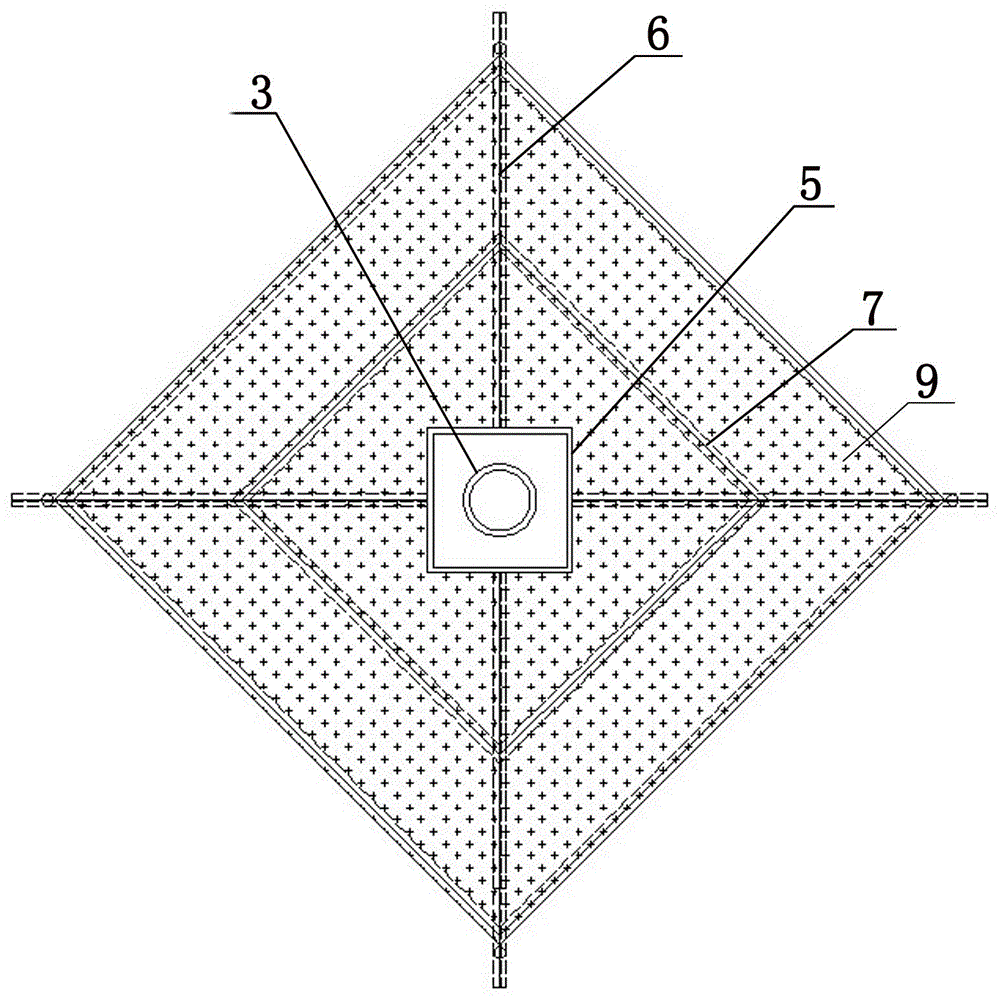

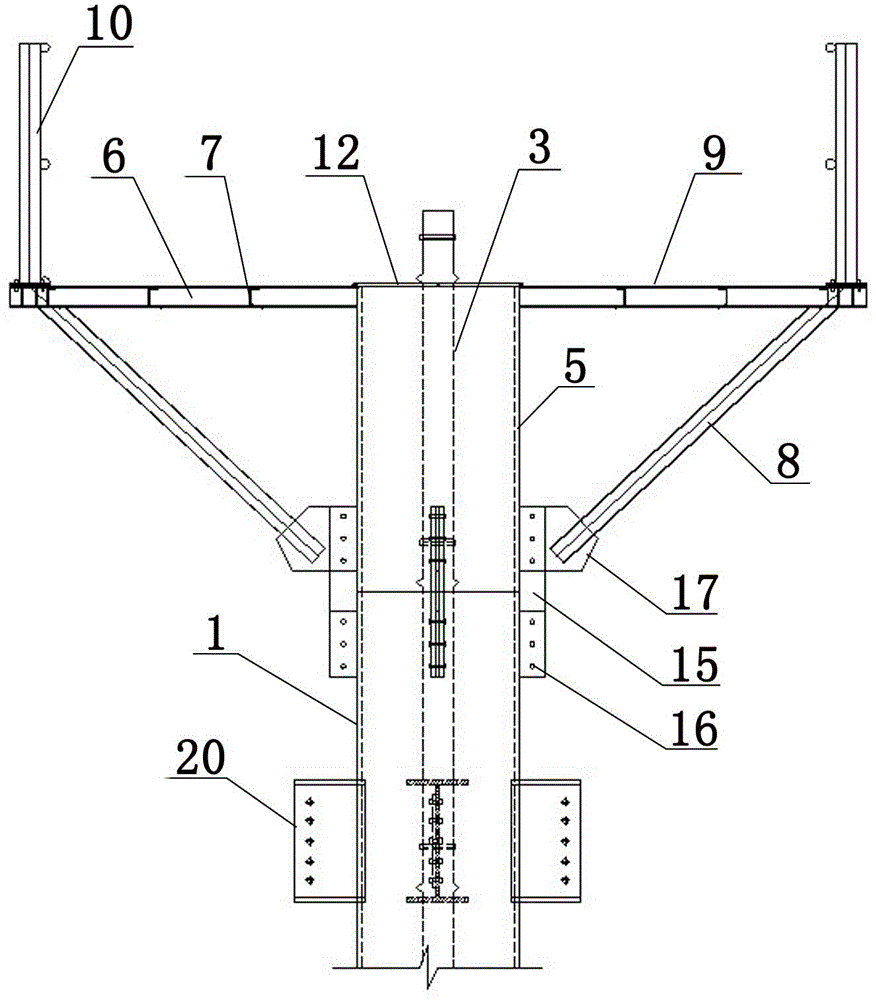

[0060] Examples see figure 1 As shown, in this ultra-high steel pipe concrete column concrete pouring device, the steel pipe 1 is provided with inner partitions 2 at intervals, the middle part of the inner partition 2 is provided with pouring holes 2.1, and air holes 2.2 are distributed around it. The device includes A movable platform on the top of the column connected to the top of the steel pipe 1, a conduit 3 inserted into the interior of the steel pipe, and a lower hopper 4 connected to the upper part of the conduit 3;

[0061] The column top movable platform is composed of joint steel pipe 5, main girder 6, secondary beam 7, diagonal brace 8, steel plate 9 and guardrail 10, and the nozzle at the top of joint steel pipe 5 is connected by hinge 11 with two clamps that can be flipped up. Plate 12, the middle of the two clamping plates 12 is provided with a conduit bayonet 12.1 for positioning the conduit, and there is also a ventilation hole 12.2 on the surface of the clamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com