Method of hoisting high altitude components

A construction method and component technology, applied in building construction, building material processing, construction, etc., can solve the problems of not being too large, increasing construction costs, etc., and achieving the effects of simple production, reduced labor intensity of workers, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

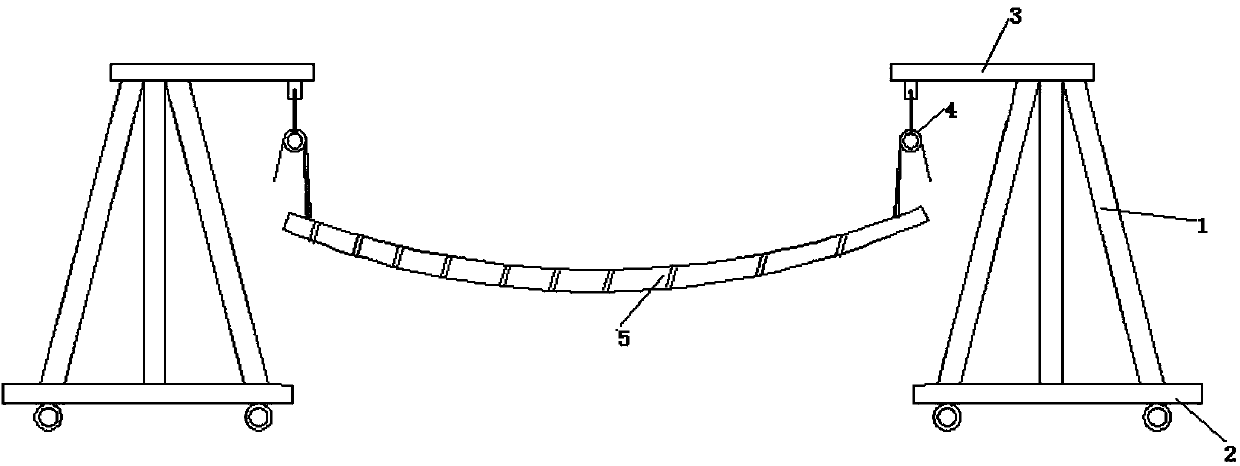

[0017] A construction method for hoisting high-altitude components, comprising the following steps:

[0018] a. The triangular steel frame 1 with the hoisting beam is fixedly connected with the steel frame of the movable chassis 2. The movable chassis 2 has rollers, and a manual hoist 4 is installed on the hoisting beam 3, and the components to be hoisted are fixed by the manual hoist 4 steel cable 5. Through the movement of the triangle steel frame 1 and the lifting of the manual hoist 4 to install and place the components, the lifting equipment is formed as a Bagan crane;

[0019] b. Move the dry crane to one end of the component to be lifted, and then adjust the counterweight of the dry crane according to the weight of the component to be lifted to form a stable lifting system;

[0020] c. When lifting the components, fix the two ends of the components to be lifted on the manual hoist cables of two different cranes and keep the lifting points at the same height, and move th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com