Metal material stress-strain curve measuring method and metal material stress-strain curve use method

A technology of metal materials and strain curves, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as warping at the end of the curve, wrong selection of materials, misleading material organization and performance changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

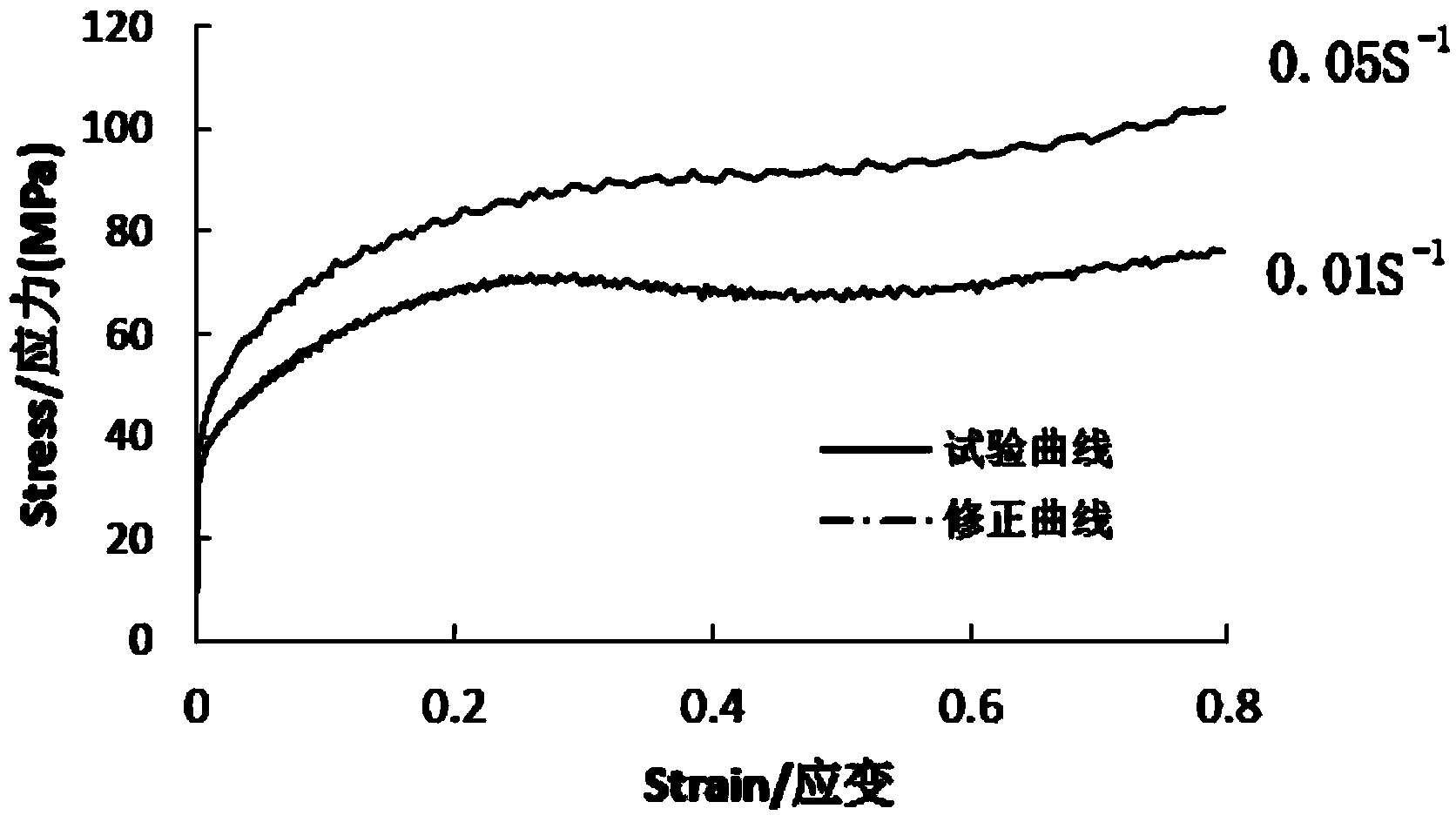

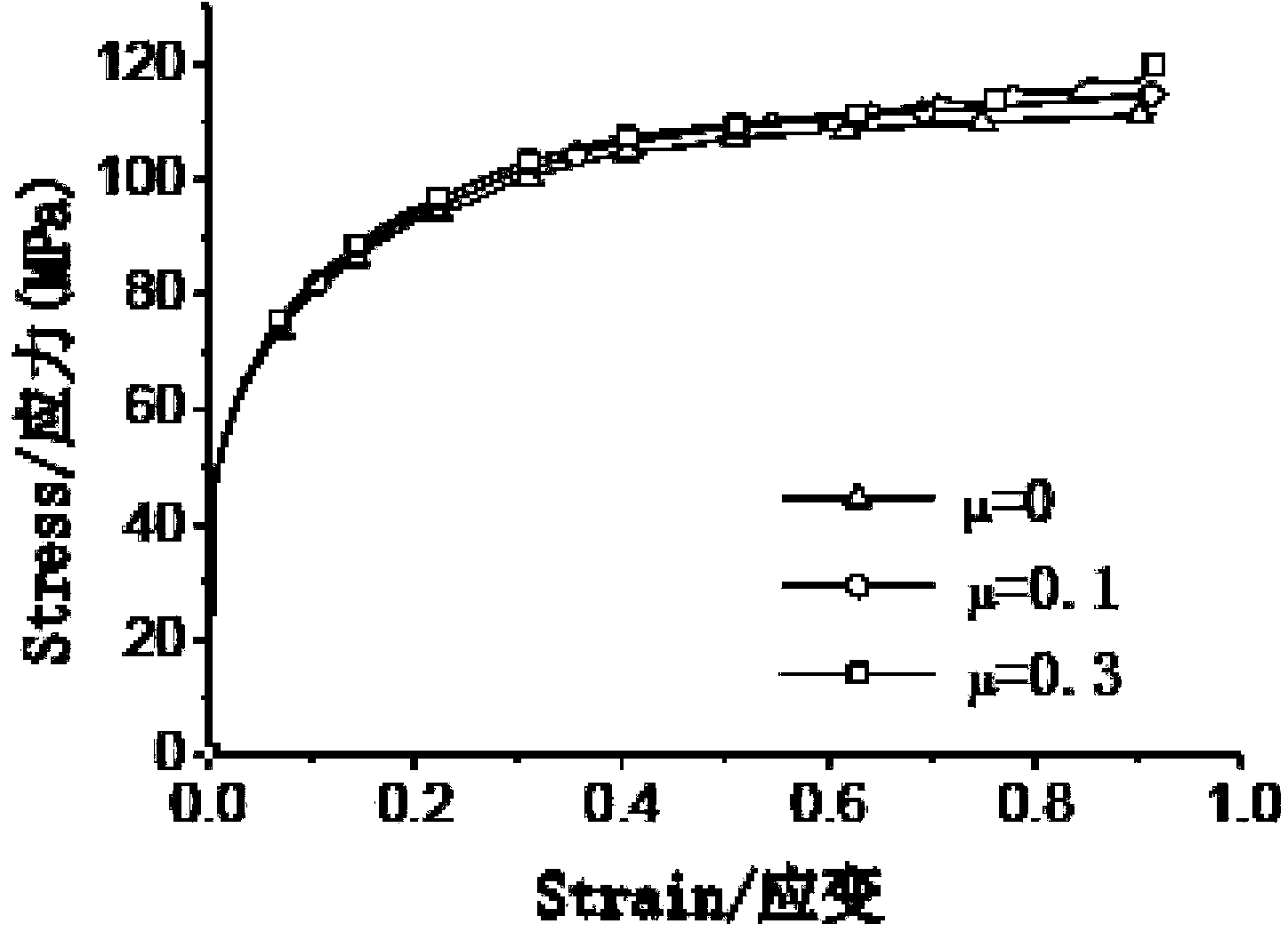

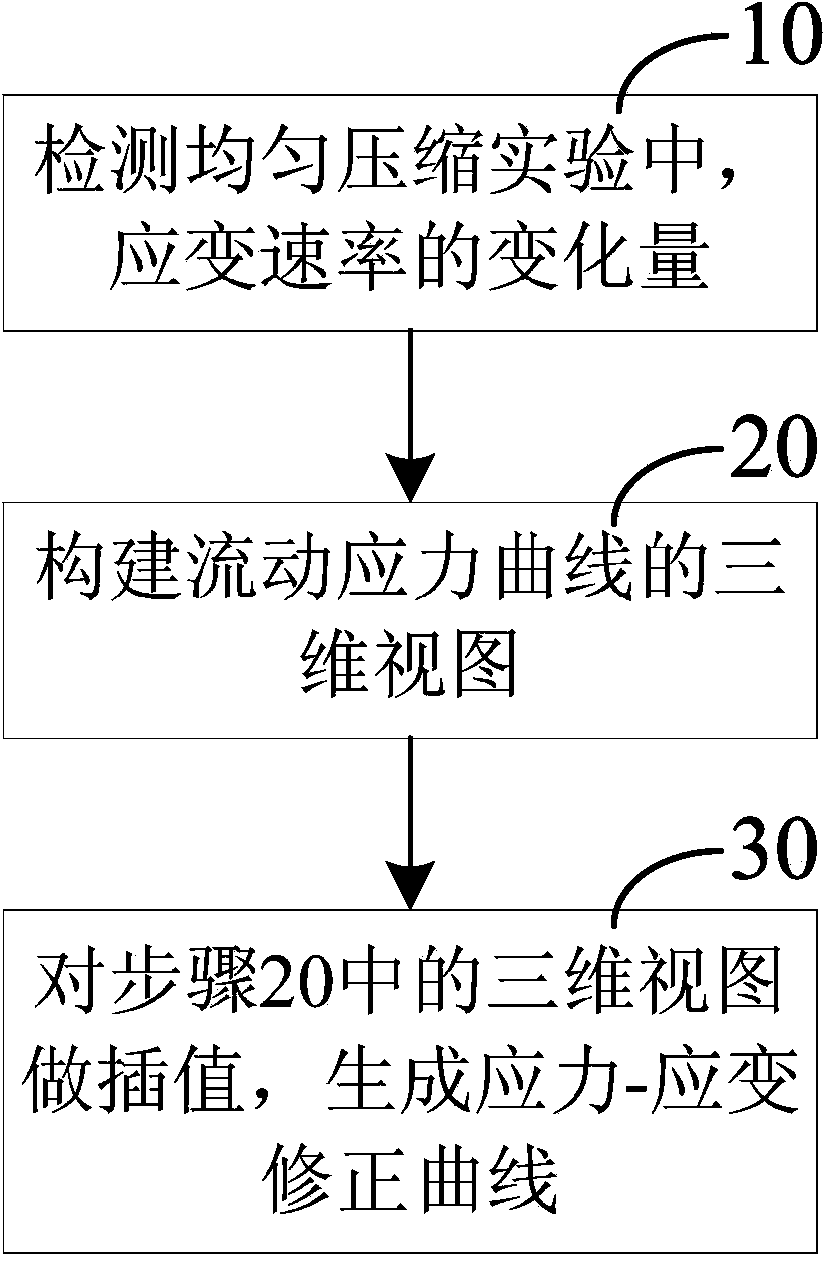

[0034] Based on the warping of the tail of the stress-strain curve found in the existing simulation experiments at high temperatures, the prior art attributed it to the increased load caused by friction. According to this, the applicant evaluates the friction factor during a large number of experiments, and only some of the tests are given as examples below. The purpose is that the law cannot be obtained under a small amount of data, and the present invention is the law obtained through a large number of experiments. , just for the convenience of description, based on the obtained rules, in turn use the following small amount of data as verification. It should be noted here that the simulation at high temperature usually refers to the temperature higher than the recrystallization temperature of metal materials and lower than the solidus. The required temperature is greater than 1200°C.

[0035] Specifically, according to common sense, the coefficient of friction of metals is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com