Stack type chip packaging structure and manufacturing method thereof

A technology of chip packaging structure and packaging structure, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

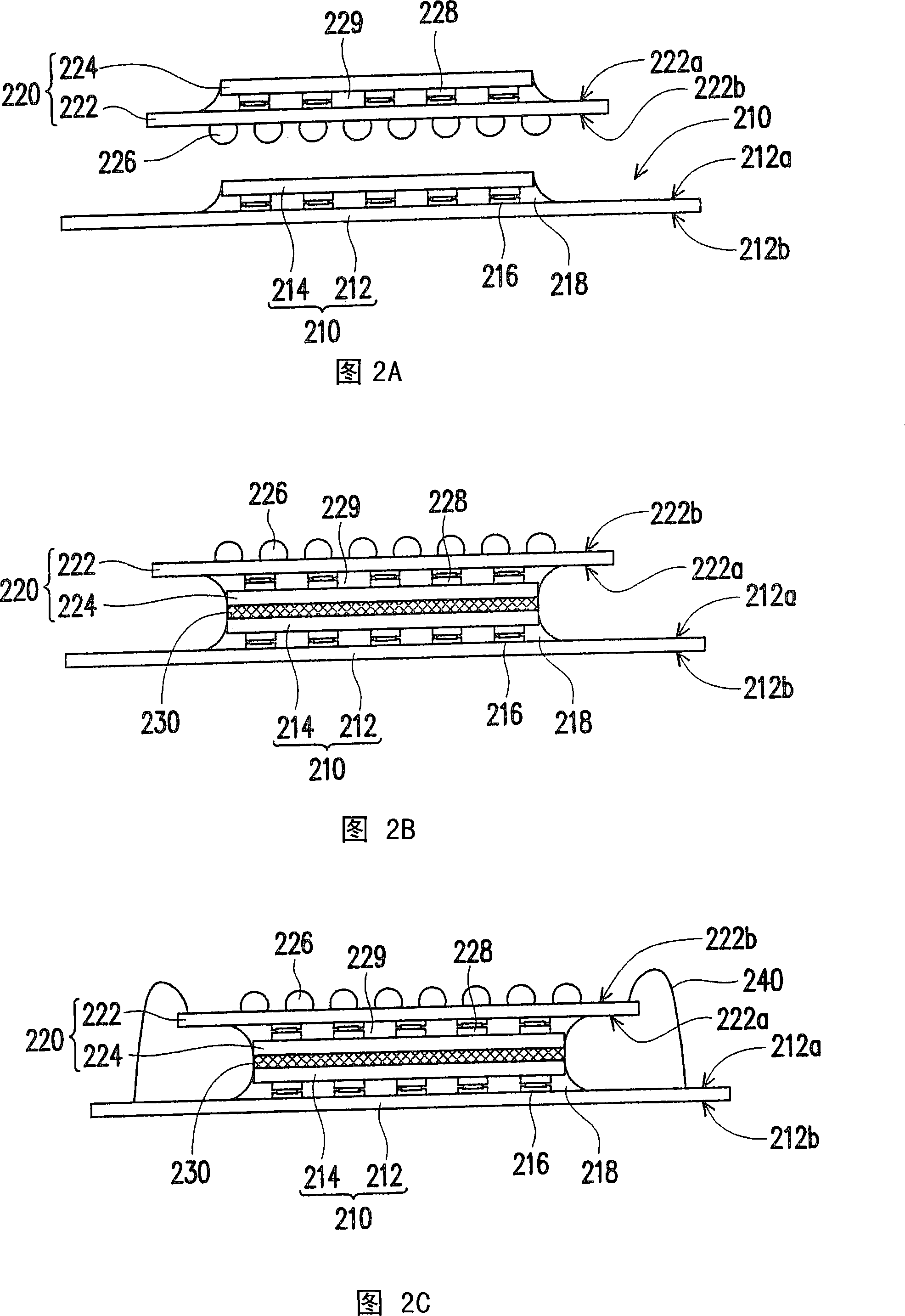

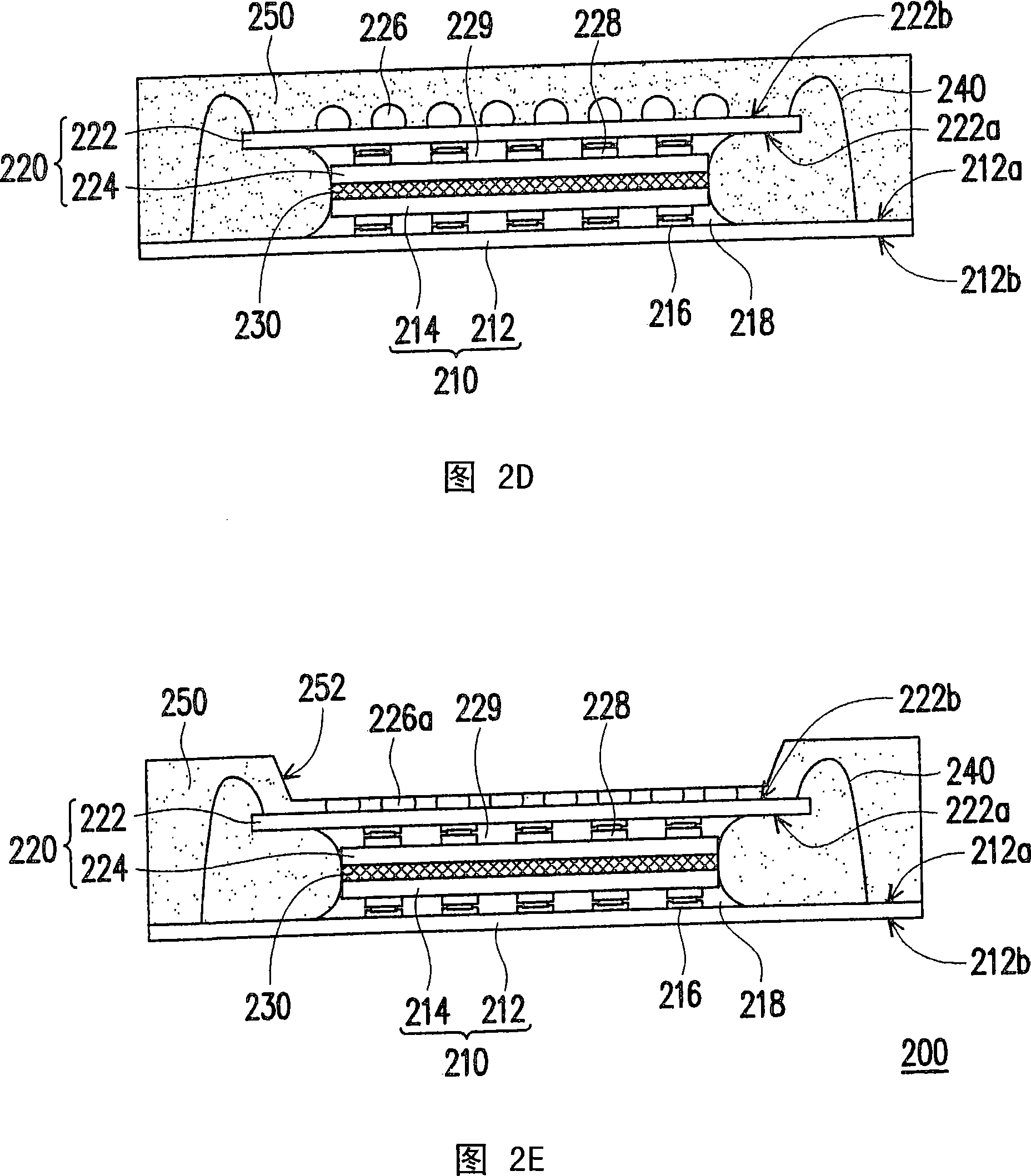

[0079] 2A-2H are schematic cross-sectional views showing a manufacturing process of a stacked chip packaging structure according to an embodiment of the present invention. First, as shown in FIG. 2A , a first packaging structure 210 and a second packaging structure 220 are provided. The first packaging structure 210 includes a first substrate 212 and a first chip 214 . The first substrate 212 has a first surface 212a and a second surface 212b corresponding thereto. The first chip 214 is disposed above the first surface 212 a of the first substrate 212 and is electrically connected to the first substrate 212 . In this embodiment, the first chip 214 is electrically connected to the first substrate 212 through a plurality of first bumps 216 . However, the first chip 214 may also be electrically connected to the first substrate 212 through other methods, which is not limited in the present invention. In addition, in order to protect the first bump 216 from damage and moisture, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com