Organic el device manufacture apparatus, deposition apparatus and deposition method thereof, liquid crystal display manufacture apparatus, alignment apparatus and alignment method

A technology for EL devices and manufacturing devices, which is applied in the field of liquid crystal display substrate manufacturing devices, can solve the problems of reduced vacuum degree, lower yield, i.e. lower productivity, blurred images, etc., to achieve reduced dust or gas, reduced deflection, and high productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

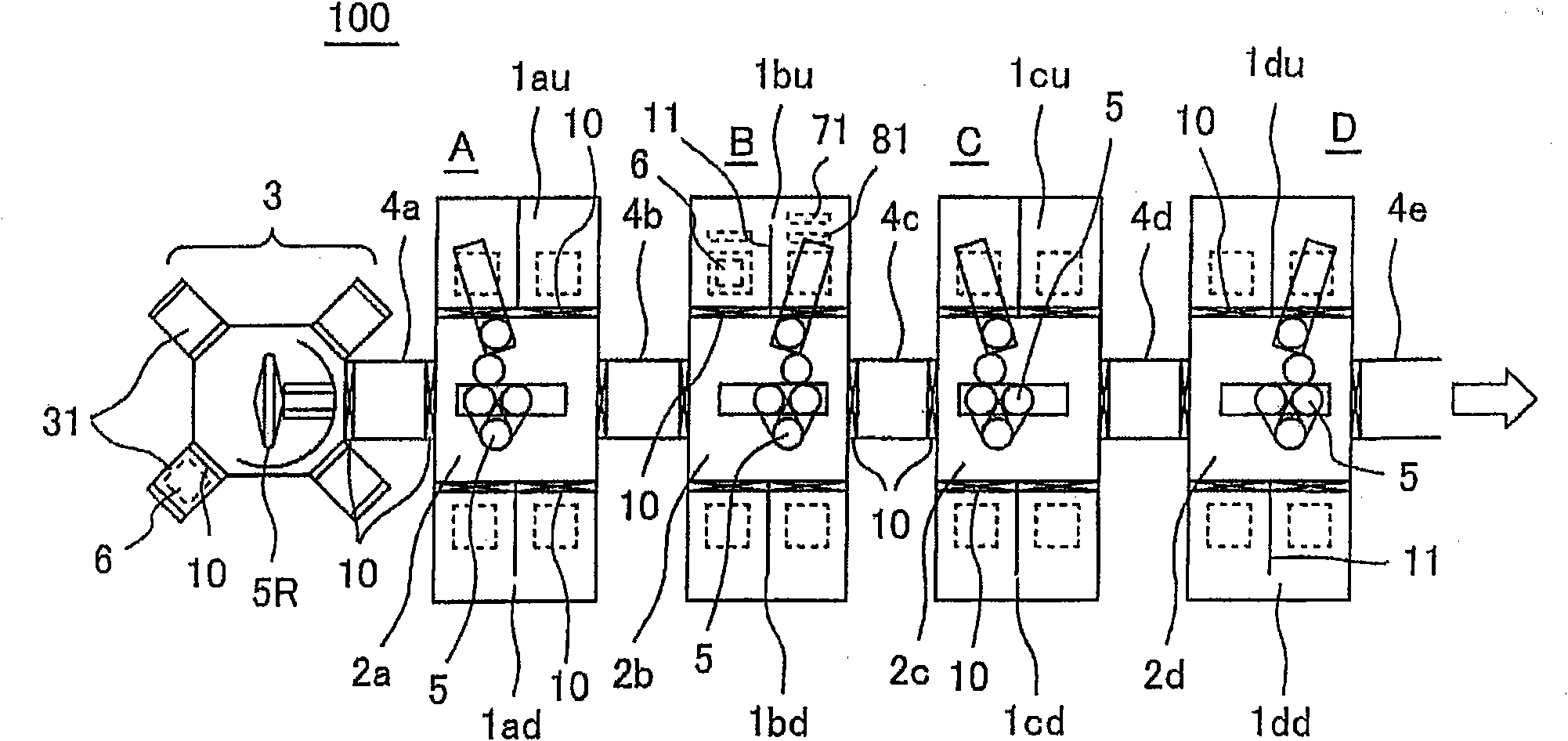

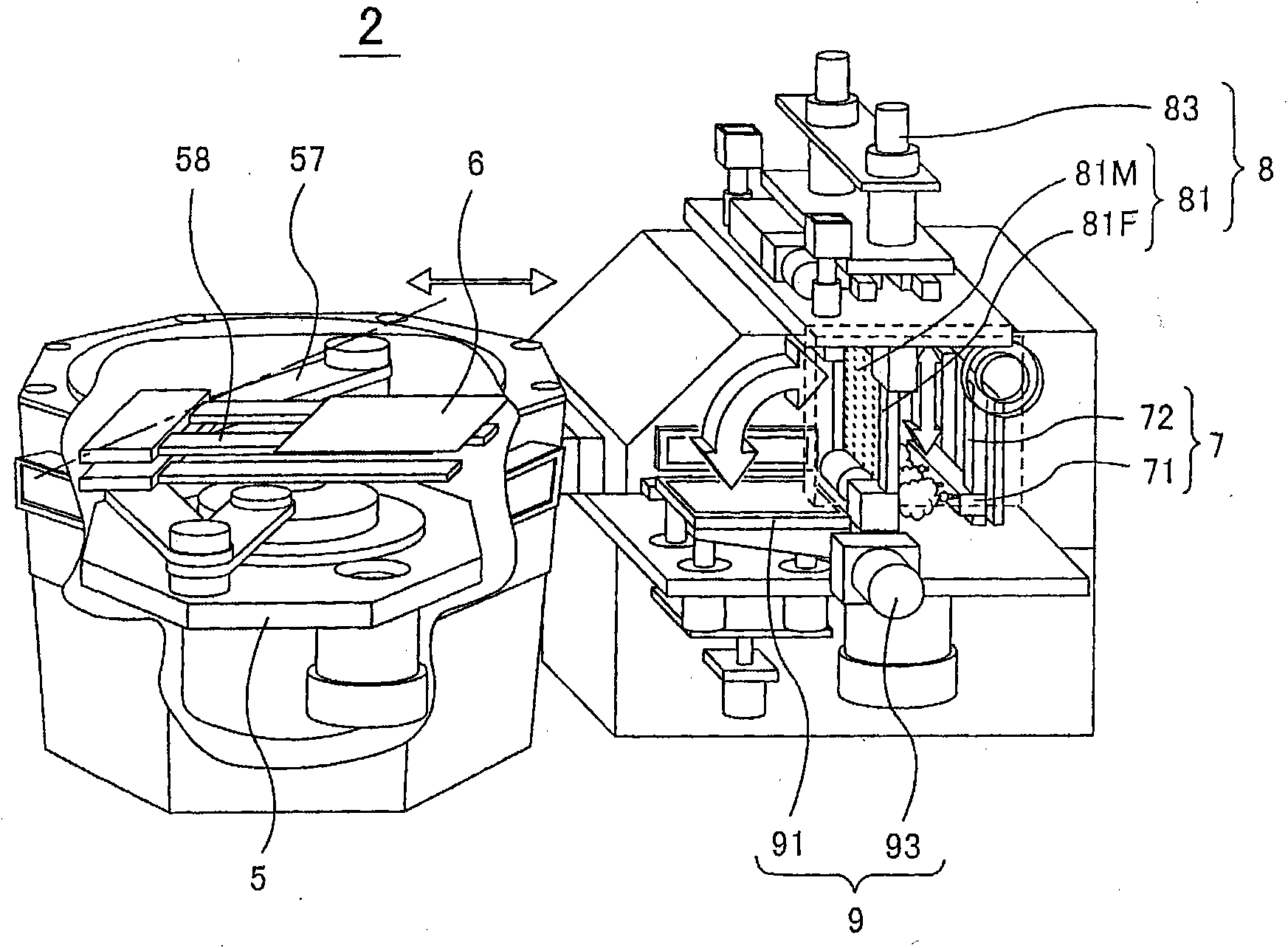

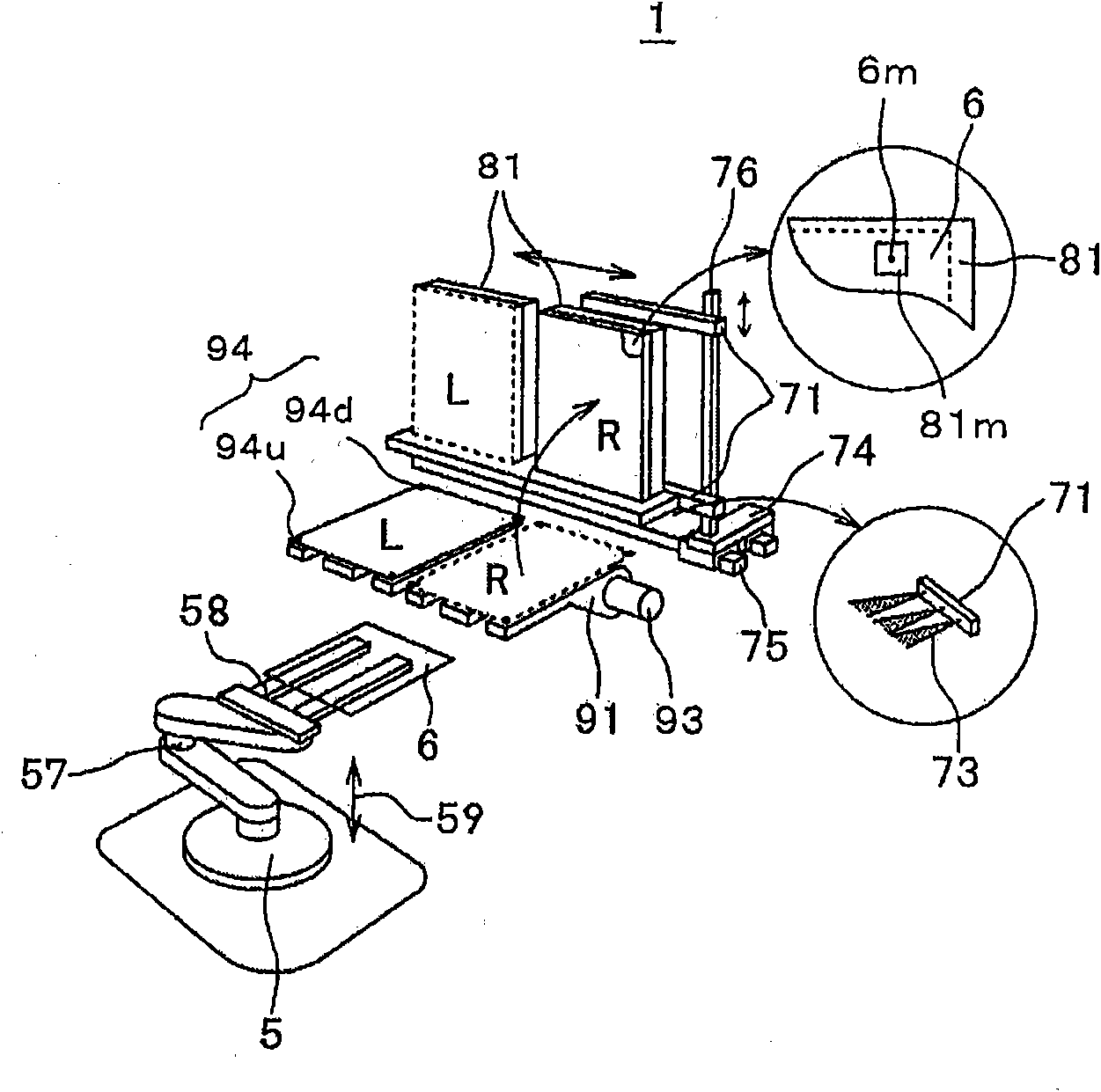

[0075] use figure 1 A first embodiment of the present invention will be described. The organic EL device manufacturing device does not only form a light-emitting material layer (EL layer) and sandwich it with electrodes. Instead, various materials are made into thin films, and a hole injection layer or transport layer is formed on the anode, and a hole injection layer or transport layer is formed on the cathode. Form a multilayer structure such as an electron injection layer or a transport layer, and clean the substrate. figure 1 An example of this manufacturing apparatus is shown.

[0076] The organic EL device manufacturing apparatus 100 of the present embodiment roughly includes: a load harness 3 carrying a substrate 6 to be processed; (Sealing process) between six transfer chambers. In this embodiment, the vapor deposition surface of the substrate is conveyed as the upper surface, and the substrate is stood up and vapor deposited during vapor deposition.

[0077] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com