Automatic sample injector having bottle pressing function and liquid chromatograph

An automatic sampling and functional technology, which is applied in the field of measurement and testing, can solve the problem that sample bottles with different heights cannot be fixed 203, etc., and achieve good fixing effect and good fixing and pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

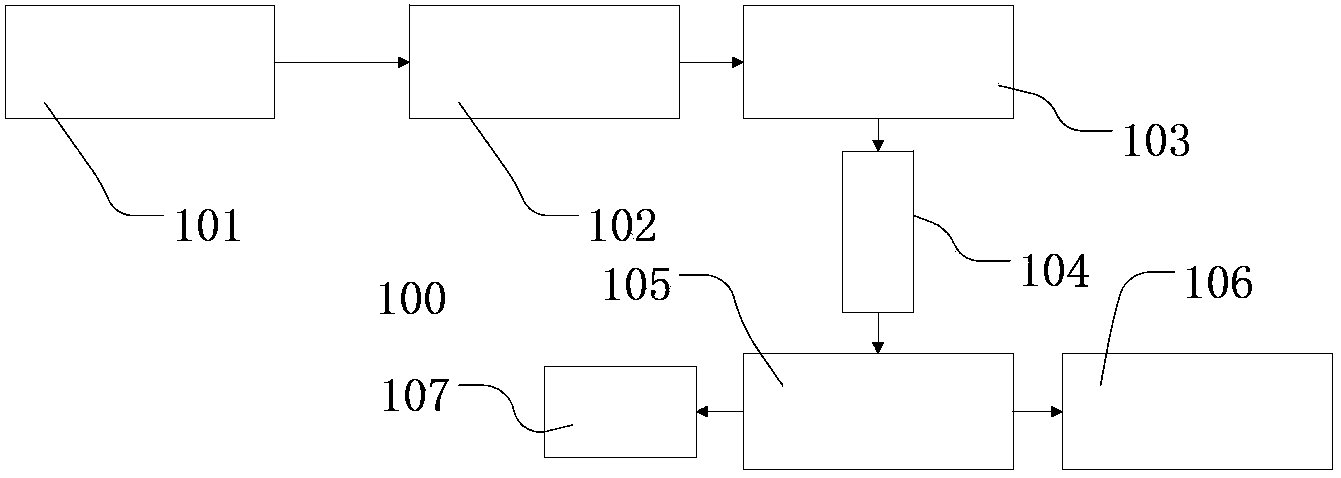

[0055] Since the liquid chromatograph of the present invention has only been improved in the autosampler part, continue to refer to figure 1 , this embodiment continues to use the liquid chromatograph 100 for description.

[0056] Since the various parts of the existing liquid chromatograph 100 have been described in the background technology, and the solvent organizer 101, infusion pump 102, chromatographic column 104, detector 105, Parts such as the analysis system 106 and the waste liquid recovery device 107 are the same as those of the prior art, and will not be repeated in this embodiment.

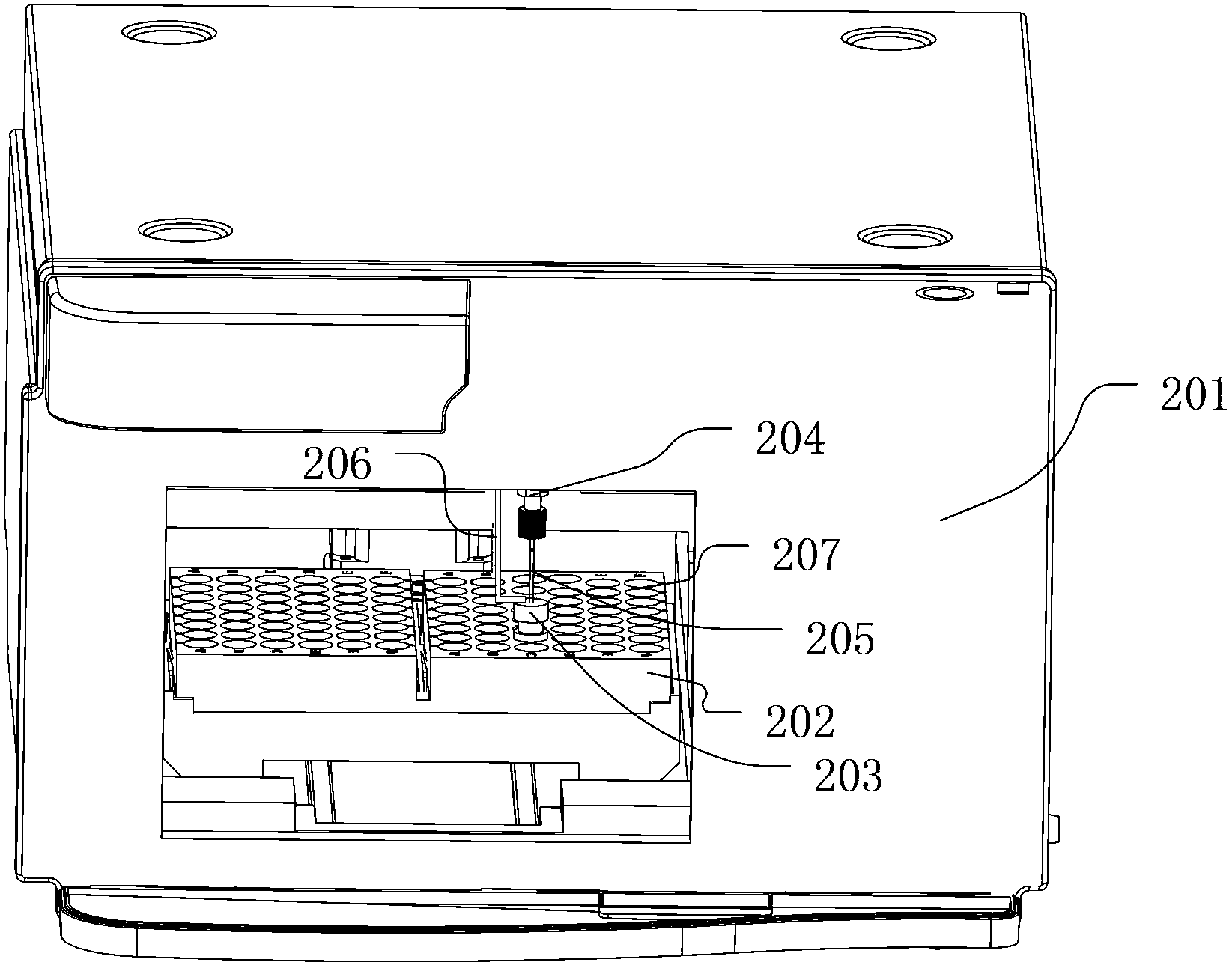

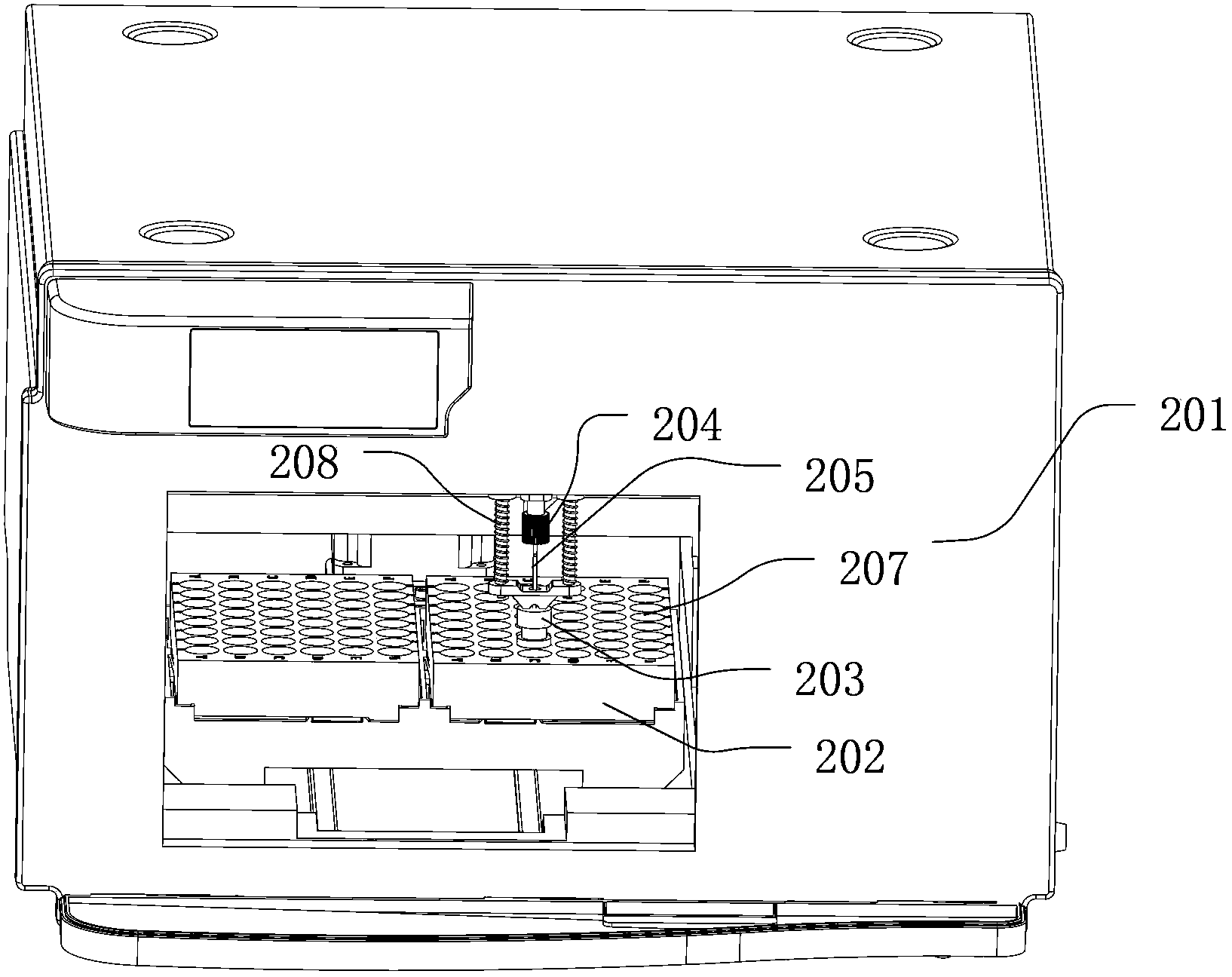

[0057] This embodiment mainly describes the autosampler 103 in the liquid chromatograph 100 . continue with reference figure 2 Compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com