Method for simulating three-dimensional light intensity distribution in thick resist ultraviolet (UV) shifting mask lithography

A technology of light intensity distribution and simulation method, which is used in microlithography exposure equipment, photolithographic process exposure devices, special data processing applications, etc., and can solve problems such as inability to simulate three-dimensional light intensity distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

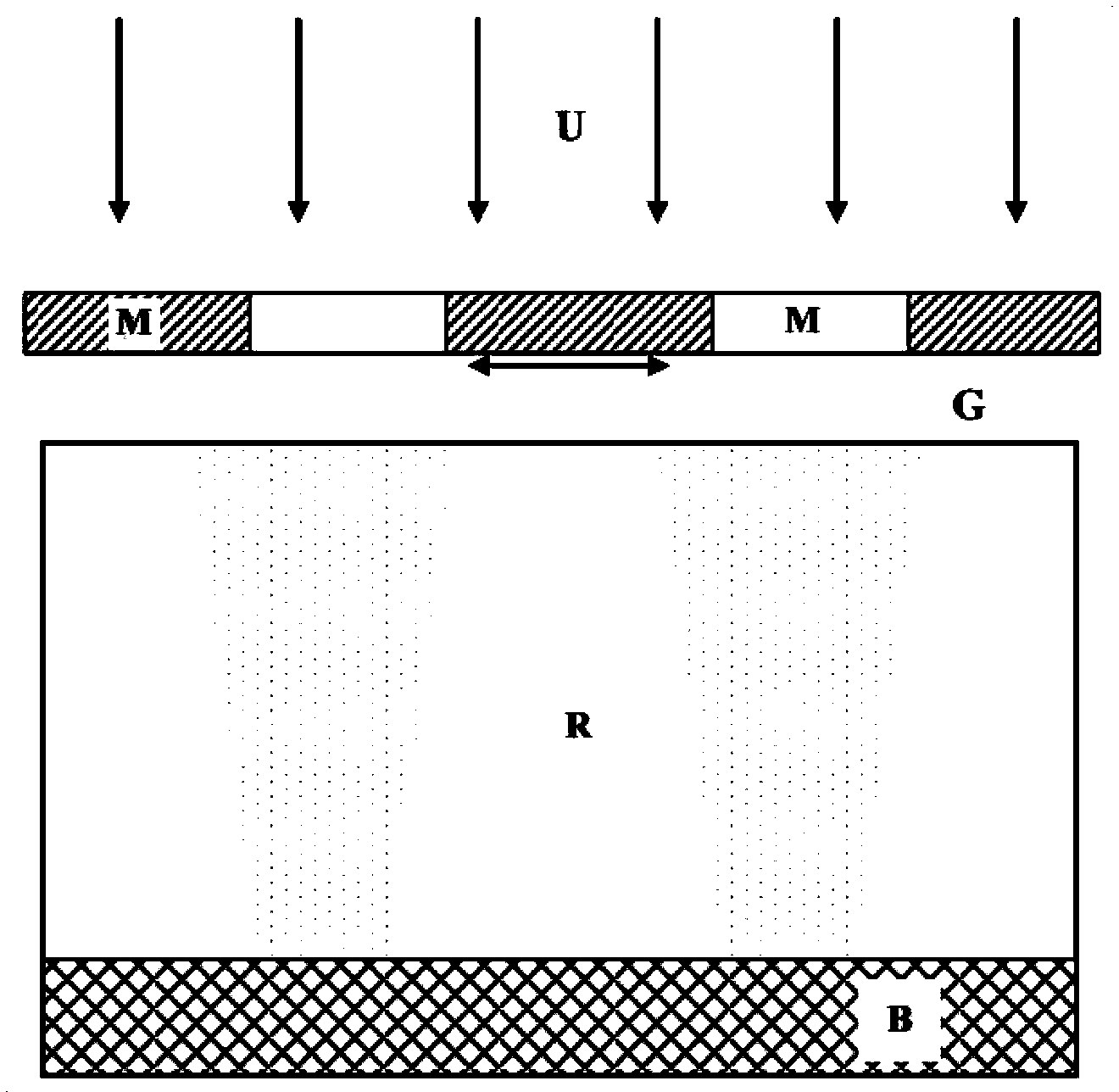

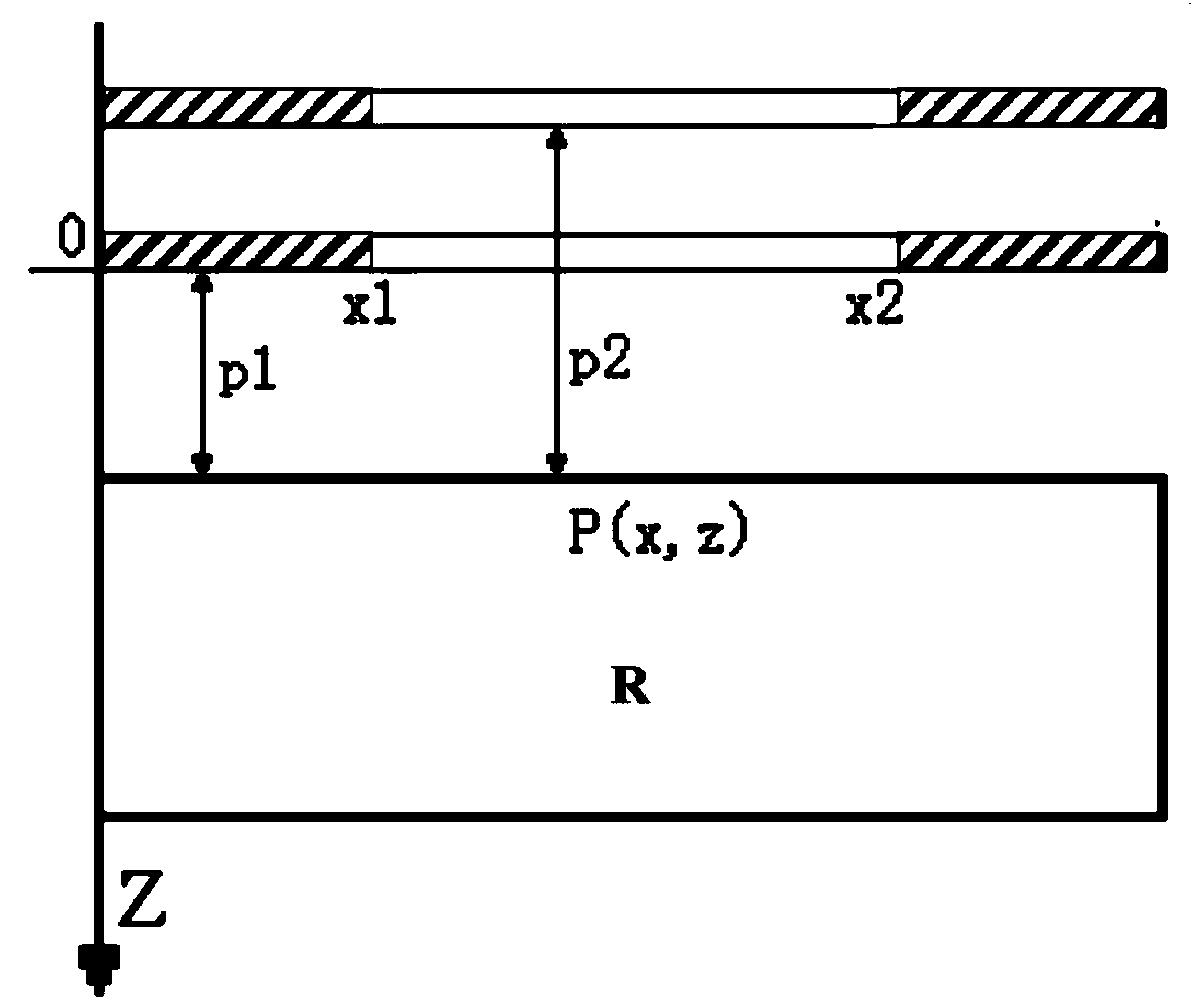

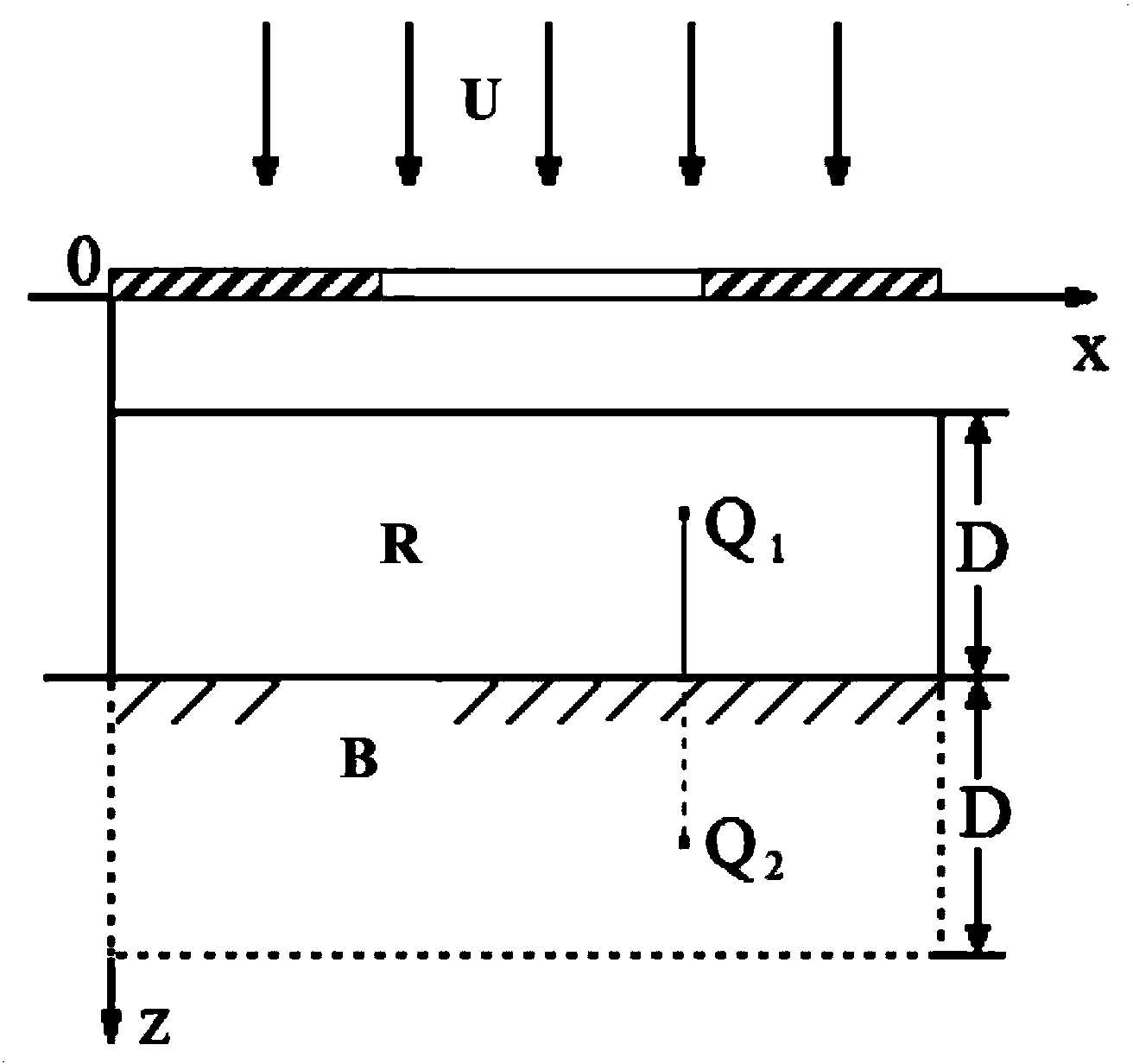

[0054] On the basis of the scalar diffraction theory, the present invention adopts the paraxial approximation technology of incident ultraviolet light to process and simplify the Fresnel-Kirchhoff diffraction integral equation, and embeds the position function of the mask plate moving with time into the static light intensity distribution to obtain Varying light intensity distribution. At the same time, the reflection and refraction effects at the air / DNQ adhesive interface and the reflection effect at the DNQ adhesive / substrate interface during the propagation of ultraviolet light, as well as the absorption factors of DNQ adhesive to ultraviolet light, were considered. It can quickly and accurately simulate the three-dimensional light intensity distribution in the process of DNQ glue UV moving mask lithography process.

[0055] Such as figure 1 As shown, the three-dimensional light intensity distribution simulation method of thick glue ultraviolet light moving mask lithograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com