Magnetic isolation squirrel cage outer rotor structure of a stator permanent magnet double rotor motor

A dual-rotor motor and outer rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of large loss, unable to fix and compress laminations, etc., and achieve the effect of reducing rotor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

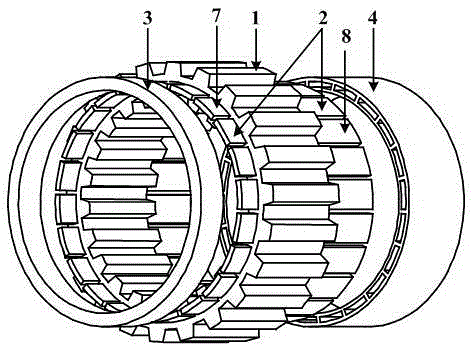

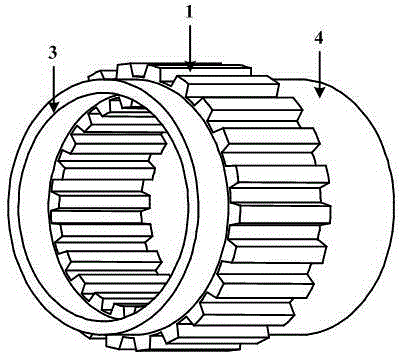

[0014] The outer rotor structure proposed by the present invention is as follows: figure 1 with figure 2 As shown, it is composed of an outer rotor body 1, a non-magnetic strip 2, a fixed end ring 3, and an output end ring 4.

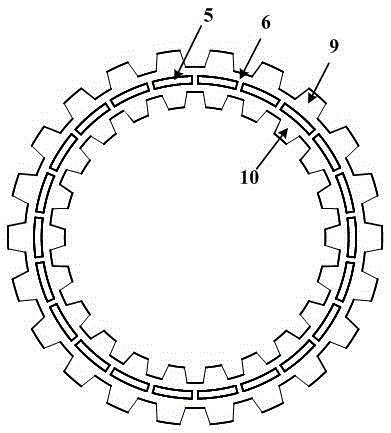

[0015] The outer rotor body 1 is laminated with silicon steel laminations 6, such as image 3 As shown, the inner and outer sides of the outer rotor body 1 are salient pole structures, and a group of closed groove groups 5 is arranged in the middle part of the yoke facing the outer salient pole 9 and the inner salient pole 10. The closed groove group 5 consists of a plurality of Composed of closed grooves with uniform direction. The axis of the closed groove group 5 is coaxial with the outer rotor body 1, the radial side walls of the closed groove group 5 are concentric arcs, the concentric arcs are coaxial with the outer rotor body 1, and the number of closed grooves is equal to that of the outer rotor body 1. The number of rotor poles on the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com