Tooth-type corncob picking device with parallel longitudinal shift wheels

A technology with parallel teeth and longitudinal direction, which is applied in the field of agricultural machinery, can solve the problems of high power consumption, low work efficiency, and bulky devices, and achieve the effects of energy saving, simple structure, and small mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

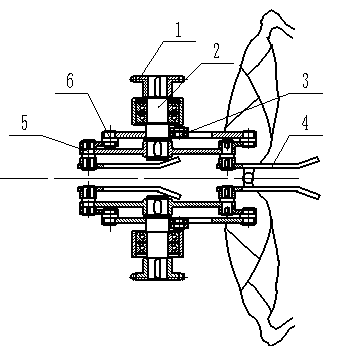

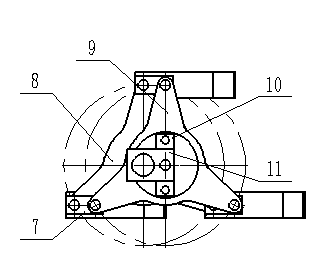

[0013] This embodiment is used to illustrate the present invention, but not to limit the present invention. Such as Figure 1~2 In the shown embodiment: the fringe breaking device is installed in front of the harvester, driven by the harvester to work. The longitudinal dial parallel gear corn ear breaking device is composed of two symmetrical ear breaking mechanisms, each group of ear breaking mechanism includes input sprocket (1), shaft 1 (2), shaft 2 (3), ear picking rod (4), shaft 3 (5), shaft 4 (6), connecting rod (7), eccentric longitudinal dial wheel 1 (8), eccentric longitudinal dial wheel 2 (9), ring wheel (10), ring inner crank ( 11) Composition, which is characterized in that the input sprocket (1) is installed at one end of the shaft 1 (2), the eccentric longitudinal dial wheel 1 (8) is installed at the other end, and the ring wheel (10) is embedded in the eccentric longitudinal dial wheel 2 (9) In the center hole, the shaft 2 (3) is hinged with the inner crank (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com