A thermal transfer printing 3D silicone clothing and its production process

A technology of heat transfer printing and clothing, applied in clothing, clothing, printing, etc., can solve the problems of combining silicone products and clothing, reduce product quality, increase production costs, etc., to facilitate publicity and display, improve product quality, and improve The effect of wear and slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

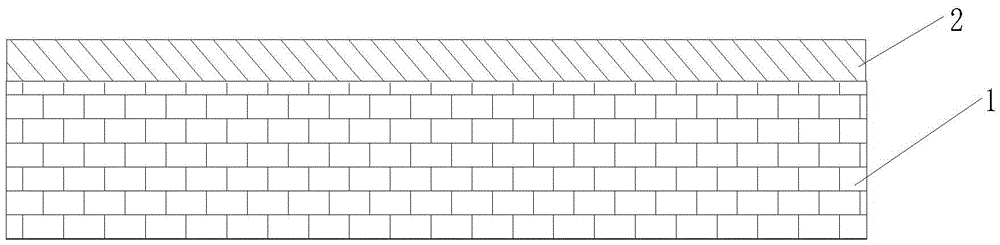

[0023] Such as figure 1 An improved clothing structure shown includes a clothing surface layer 1 , and a silicone layer 2 is thermally transferred on the top of the clothing surface layer 1 . The setting position of the silica gel layer 2 can be on various positions such as cuffs, neckline, and chest. Preferably, the silica gel layer 2 is made of silica colloidal material added with a brightening agent. It is also possible to set a reflective layer on the outer layer of the silica gel layer 2 . In order to enhance air permeability, air holes can also be provided on the silica gel layer 2 .

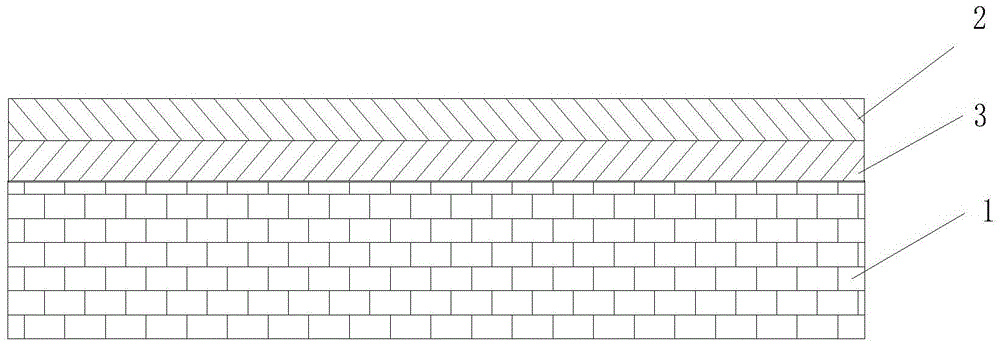

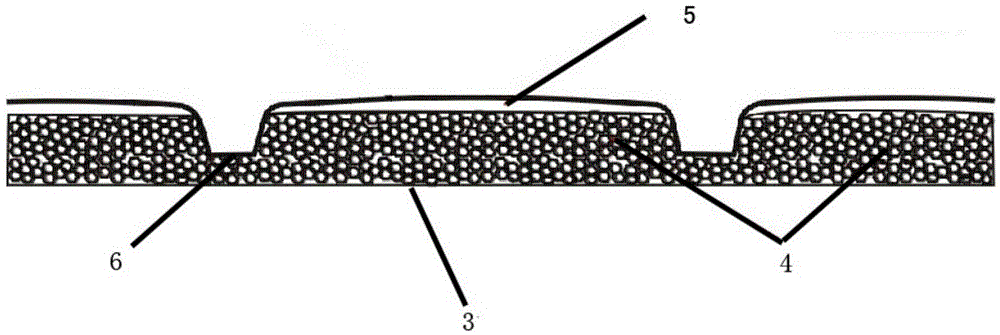

[0024] Such as figure 2 and image 3 As shown, a buffer layer 3 is also provided between the silica gel layer 2 and the clothing surface layer 1 . The buffer layer 3 forms a plurality of symmetrical buffer modules 4, and an air layer 5 is arranged between the buffer modules 4 and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com