Rear LED combined lamp

An LED module, LED lamp bead technology, applied in the cooling/heating device of lighting device, motor vehicle, lighting and heating equipment, etc., can solve the problem of high development cost and mold manufacturing cost, unreasonable lighting structure layout, day The large size of the running lights can reduce the development and mold manufacturing costs, the appearance is beautiful, the energy-saving practicability, and the space volume of the lamps can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

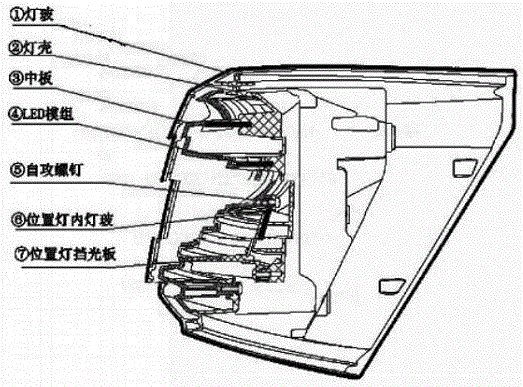

[0020] figure 1 Shown is a cross-sectional view of the structure of the LED rear combination lamp of the present invention, as figure 1 , an LED rear combination car light, consisting of a lamp glass (1), a lamp housing (2), a middle plate (3), an LED module (4), self-tapping screws (5), and a position lamp inner lamp glass (6) . The position lamp light baffle (7) is sealed and assembled, and it is characterized in that: the LED module (4) consists of a position lamp LED module, a brake light LED module, a reversing light LED module, and a turn signal LED module composition, the position lamp inner lamp glass (6) is connected with the position lamp light shield (7) by self-tapping screws (5), the middle plate (3) is parallel to the LED template (4) and is 1cm-5cm apart, The thickness of the lamp glass (6) in the position lamp is 1.5mm-2.0mm.

[0021] It should be noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com