Fragrant cloth and preparing method thereof

A technology of fragrance and fragrance agent, applied in the field of textile fabrics, can solve the problems of human health effects, poor fragrance persistence, etc., and achieve the effects of simple preparation method, long-lasting fragrance, and good electrical and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment prepares the cloth with fragrance according to the preparation method of following steps:

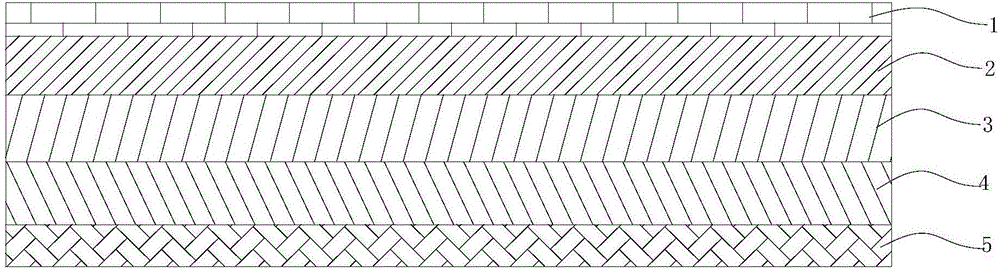

[0036] 1) The yarn made by twisting acrylic fibers and cotton fibers is used as warp and weft yarns to weave the fabric, and the upper surface of the fabric is pressed with a three-dimensional pattern by hot pressing to form a pattern layer 2, wherein the pattern layer 2 is a three-dimensional apple pattern;

[0037] 2) The polyurethane film on the upper surface of the pattern layer 2 prepared in step 1) forms a fabric with a waterproof and moisture-permeable layer 1 and a pattern layer 2 sequentially from top to bottom;

[0038] 3) coating silver on the surface of acrylic fibers to make silver fibers, twisting silver fibers with multiple silver fibers to prepare silver yarns, and using silver yarns as raw materials to prepare silver fiber fabrics;

[0039] 4) scented fabrics are prepared from scented fibers made from acrylic fibers and flavoring agents; wher...

Embodiment 2

[0042] The present embodiment prepares the cloth with fragrance according to the preparation method of following steps:

[0043] 1) The yarn made by twisting polyester fiber and cotton fiber is used as warp and weft yarn to weave the fabric, and the upper surface of the fabric is hot-pressed to form a three-dimensional pattern to form a pattern layer 2, wherein the pattern layer 2 is a three-dimensional mango pattern;

[0044] 2) The polyurethane film on the upper surface of the pattern layer 2 prepared in step 1) forms a fabric with a waterproof and moisture-permeable layer 1 and a pattern layer 2 sequentially from top to bottom;

[0045] 3) Coating silver on the surface of polyester fibers to make silver fibers, twisting with multiple silver fibers to prepare silver yarns, and using silver yarns as raw materials to prepare silver fiber fabrics;

[0046] 4) fragrance fabrics are prepared from polyester fibers and fragrance fibers made from fragrance agents; wherein, the prepa...

Embodiment 3

[0049] The present embodiment prepares the cloth with fragrance according to the preparation method of following steps:

[0050] 1) The yarn made by twisting polyester fiber and cotton fiber is the warp and weft weaving fabric, and the upper surface of the fabric is pressed with a three-dimensional pattern by hot pressing to form a pattern layer 2, wherein the pattern layer 2 is a three-dimensional osmanthus pattern;

[0051] 2) The polyurethane film on the upper surface of the pattern layer 2 prepared in step 1) forms a fabric with a waterproof and moisture-permeable layer 1 and a pattern layer 2 sequentially from top to bottom;

[0052] 3) Coating silver on the surface of polyester fibers to make silver fibers, twisting with multiple silver fibers to prepare silver yarns, and using silver yarns as raw materials to prepare silver fiber fabrics;

[0053] 4) fragrance fabrics are prepared from polyester fiber and fragrance fibers; wherein, the preparation process of fragrance f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com