Evaporated fuel treatment device

A technology for evaporating fuel and processing device, applied in the field of evaporating fuel processing device, can solve the problems of large airflow resistance and inability to ensure air permeability, and achieve the effects of reducing cost and reducing position changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

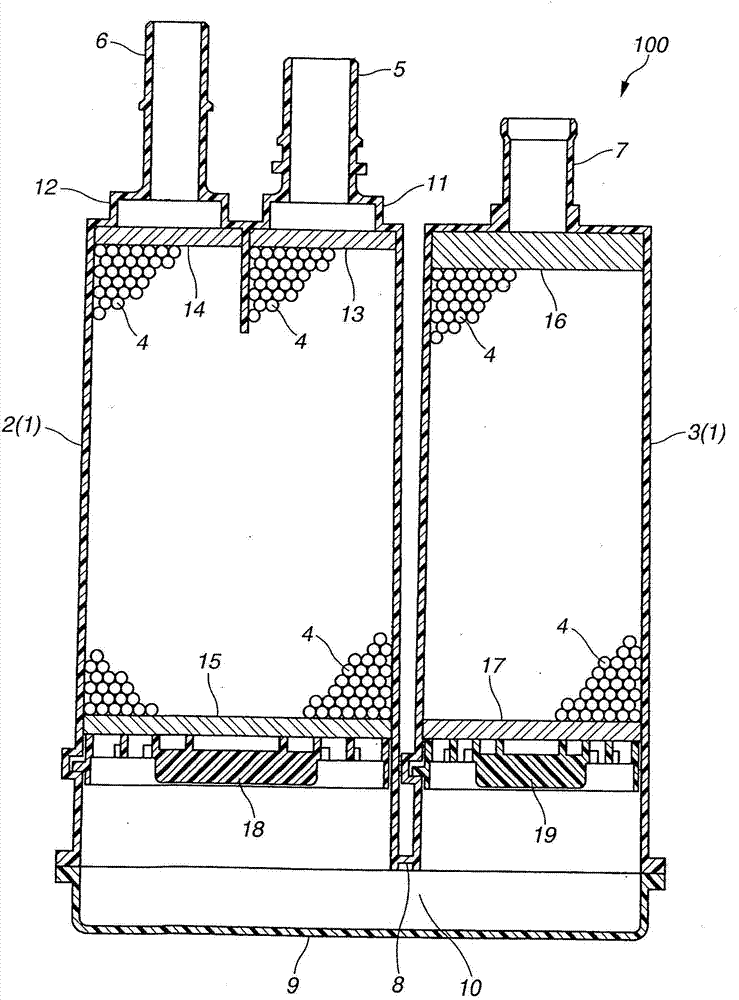

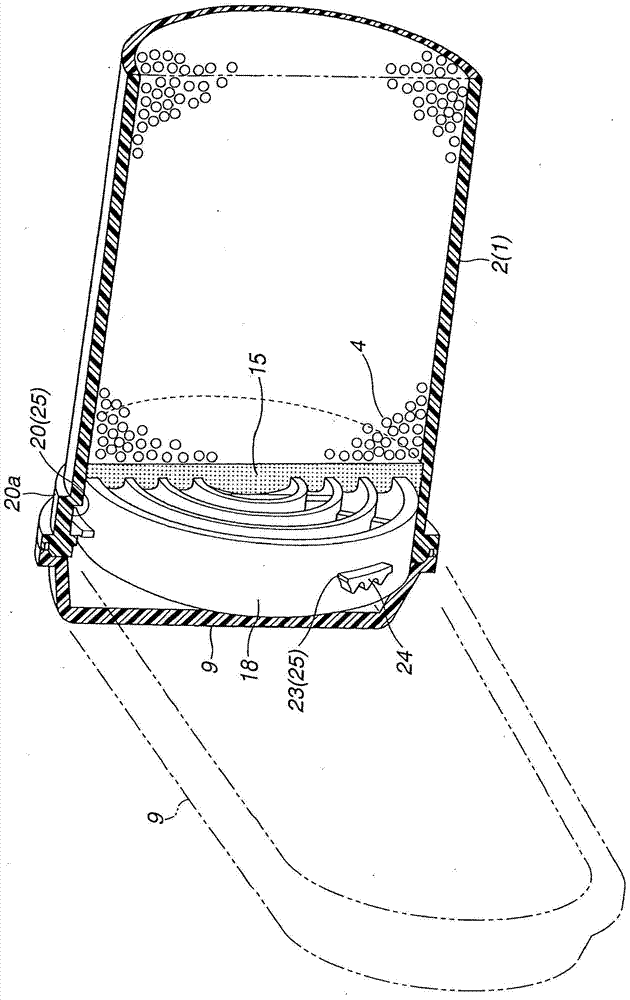

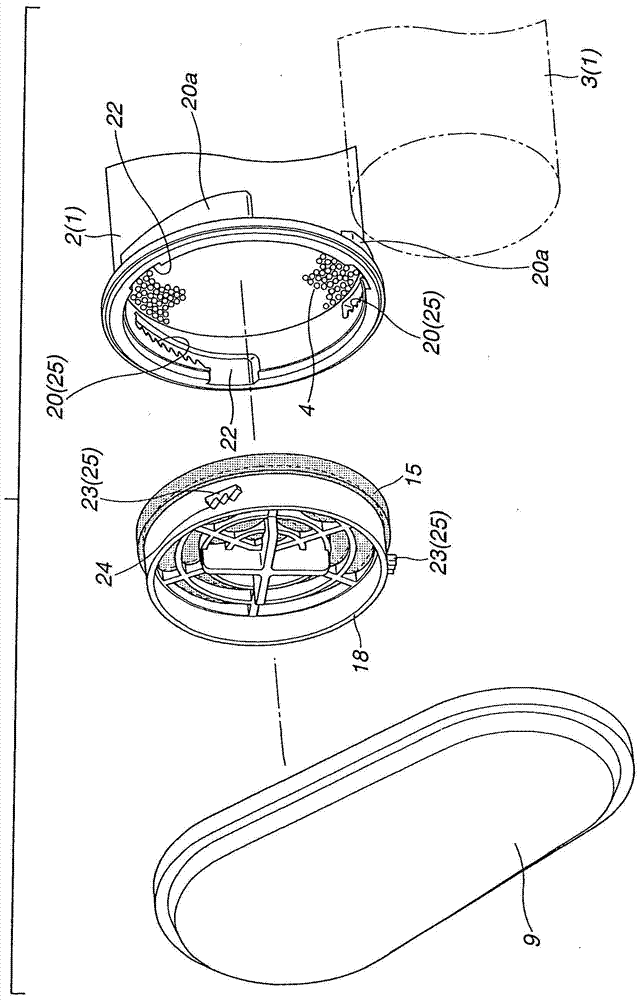

[0035] refer to Figure 1 to Figure 5 , an evaporated fuel processing device (hereinafter simply referred to as a canister) according to a first embodiment of the present invention will be explained hereinafter. figure 1 A cross-section of a so-called two-chambered tank is shown as a whole. Figure 2 to Figure 5 show figure 1 Details of the tank shown in the construction.

[0036] Such as figure 1 As shown in , the tank 100 includes a sealed casing 1 and an adsorbent 4 filled in the casing 1 . Adsorbent 4 is granular activated carbon. The granular activated carbon can be generally in the form of granular carbon particles or pulverized carbon particles. The housing 1 comprises a filling port 5 , a purge port 6 , an atmospheric vent 7 and a cover part 9 . A cover member 9 is arranged at one end of the housing 1 . A filling port 5 , a purge port 6 and an atmospheric vent 7 are arranged at the other end of the housing 1 .

[0037] Specifically, the housing 1 includes two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com