Manual stainless steel punching machine

A punching machine and stainless steel technology, applied in the field of manual stainless steel punching machines, can solve the problems of complex device structure, single function, poor practicability, etc., and achieve the effects of high safety performance, stable product quality and light machinery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

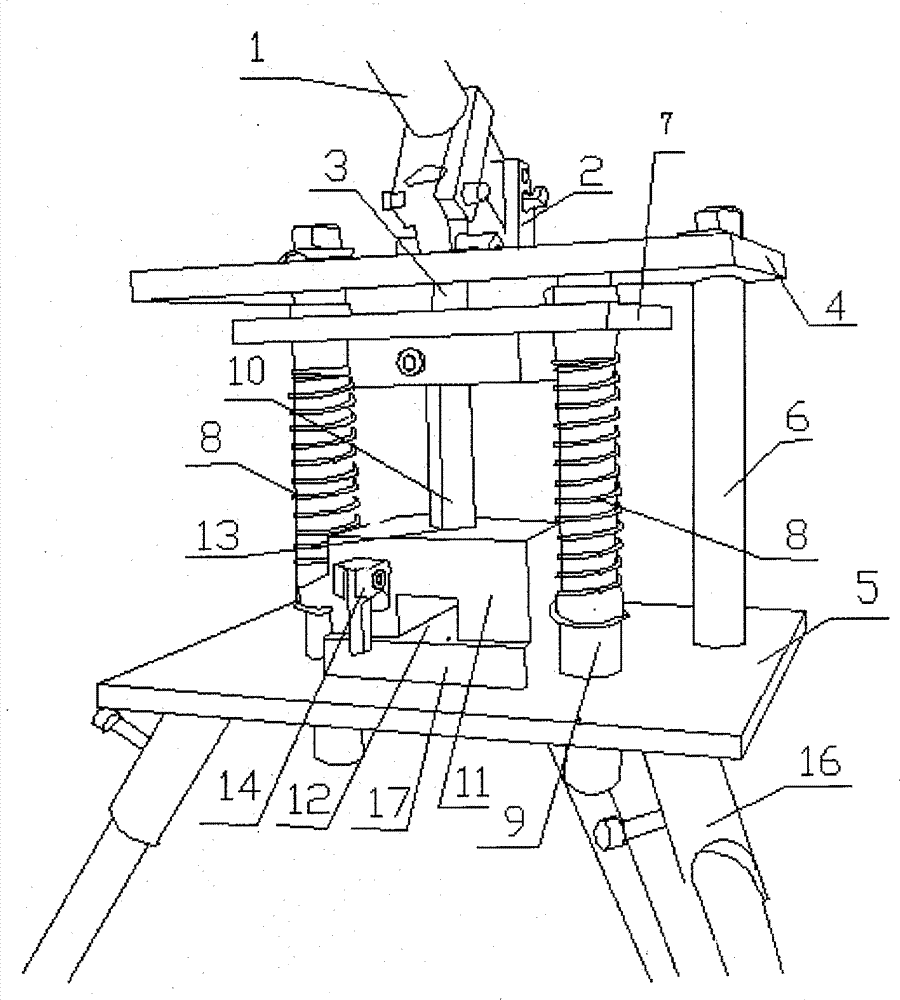

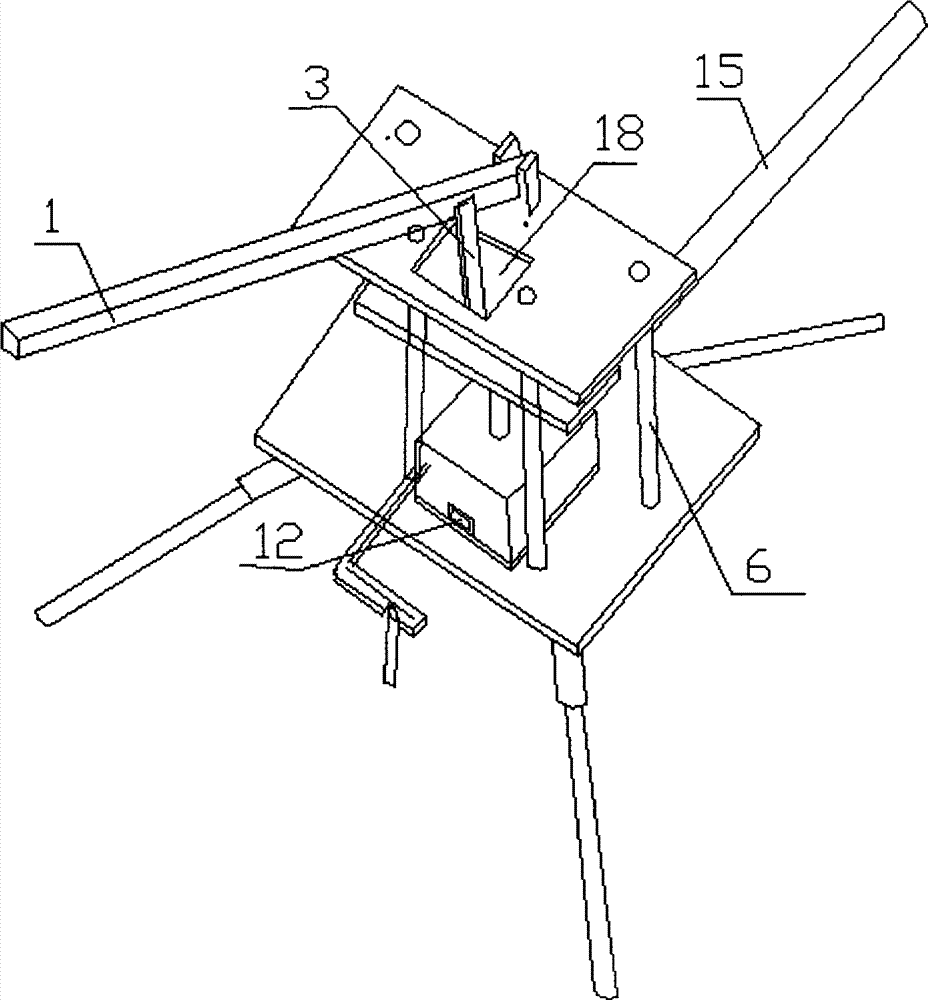

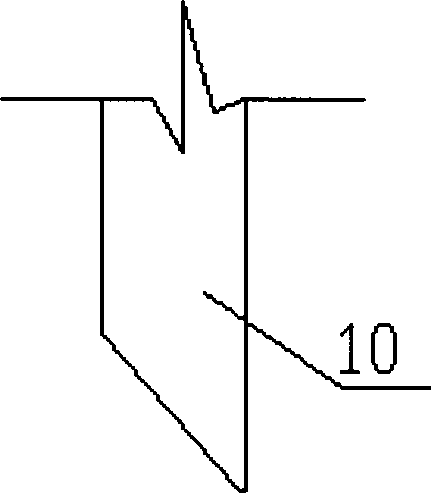

[0028] according to Figure 1-Figure 3 As shown, the present invention mainly includes: pressure rod 1, connecting seat 2, connector 3, upper machine plate 4, lower machine plate 5, fixed column 6, slide plate 7, spring 8, guide column 9, punch 10, mold body 11. Mold core 12, guide hole 13, positioning rod 14, mold core rod 15, bracket 16, lower template 17, access hole 18,

[0029] Manual stainless steel punching machine: the front end of the pressure rod 1 is movably connected with the connection seat 2 provided on the upper machine plate 4, and the lower parts of both sides of the upper machine plate 4 are symmetrically fixed and fixed with fixed columns 6, and the fixed columns 6 are fixedly connected with the lower machine plate 5 The front portion of the depression bar 1 is fixedly connected with the connector 3, and the connector 3 is fixedly connected with the slide plate 7 through the access hole 18 provided on the upper machine plate 4, and the slide plate 7 is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap