Method for machining roller cage

A processing method and cage technology, which are applied in the field of roller cages, can solve the problems of many process steps, difficulty in meeting the needs of reducing costs, and chips in processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed content and technical description of the present invention are now further described with examples, but it should be understood that these examples are for illustrative purposes only, and should not be construed as limitations on the implementation of the present invention.

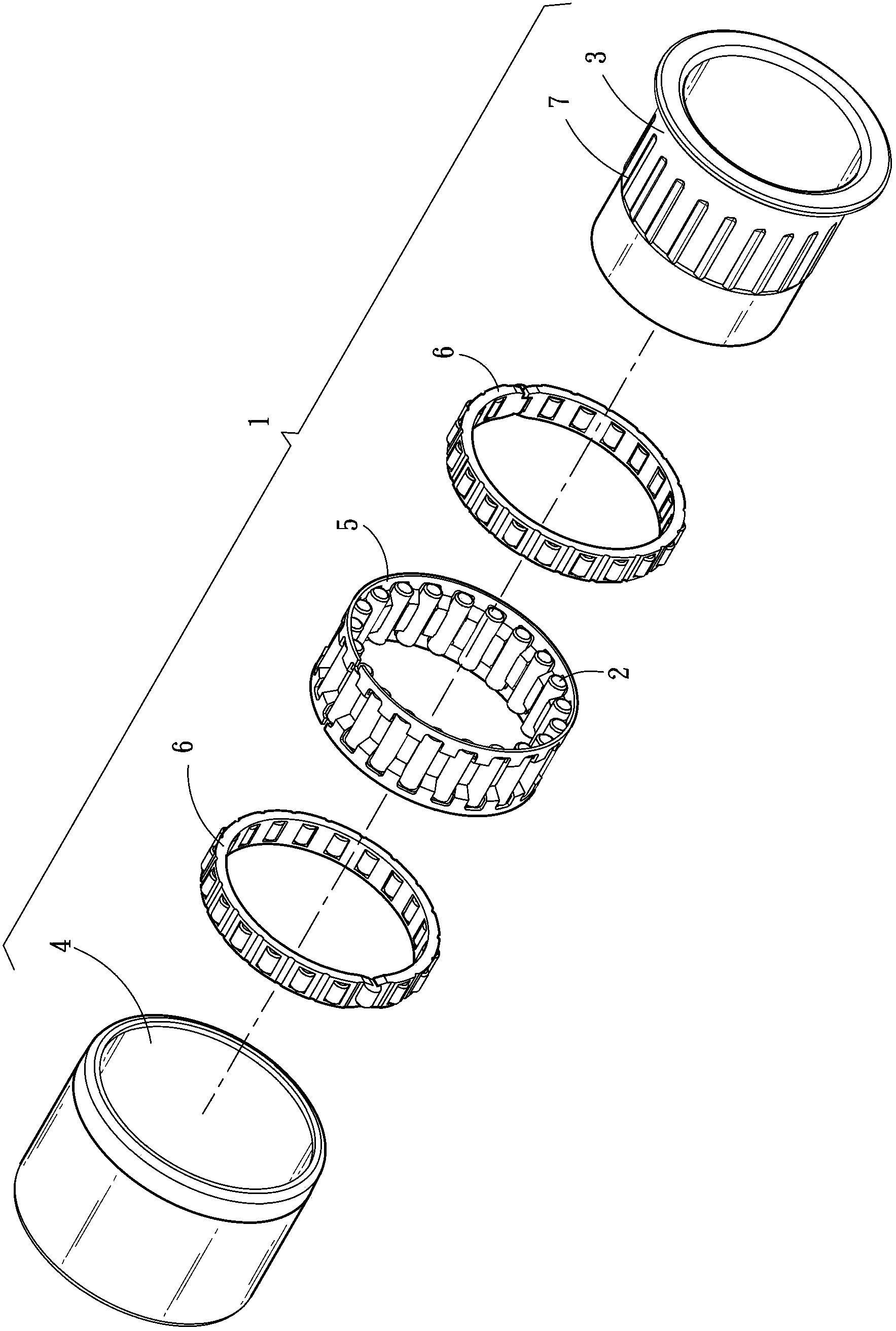

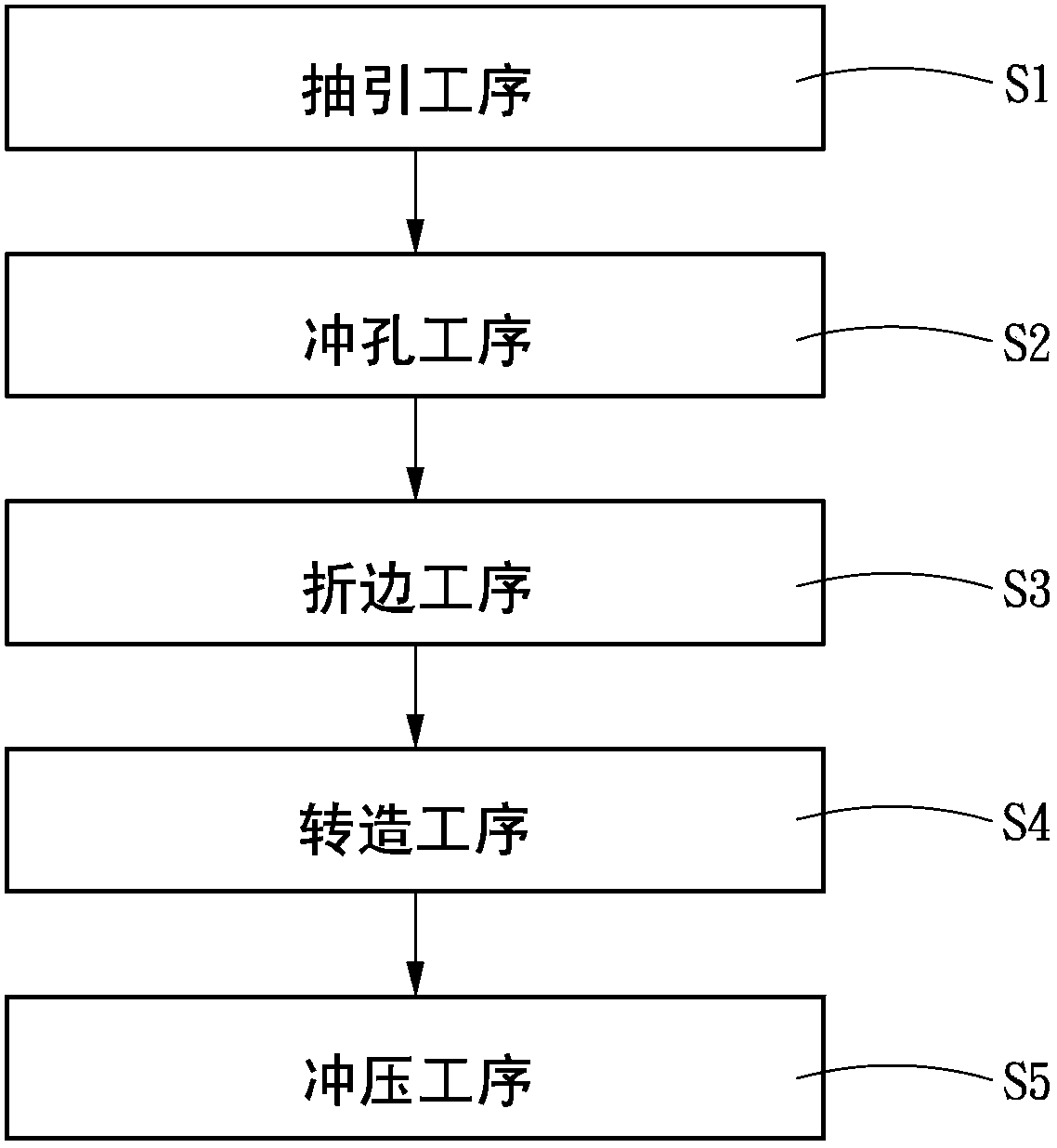

[0020] see image 3 , Figure 4 and Figure 5 As shown, the present invention is a roller cage processing method for forming a flat plate 10 into a roller cage 20. The steps include a drawing process S1, a punching process S2, and an edge folding process. S3, a transformation process S4 and a stamping process S5.

[0021] see again Figure 6 As shown, the extraction process S1 is to form the flat plate 10 into a sleeve 30 with a closed end 31 and an open end 32, and in order to increase the processing accuracy and avoid excessive deformation in a single forming, the extraction The drawing process S1 may include multiple drawing procedures, so as to gradually form the sleeve 30 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com