Progressive mold pressing technology and device for car door trim panel made of natural fiber composite material

A technology of natural fibers and composite materials, applied in lamination devices, lamination, metal processing, etc., can solve the problems of inaccurate size and shape of interior panels, achieve good environmental performance, facilitate recycling, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

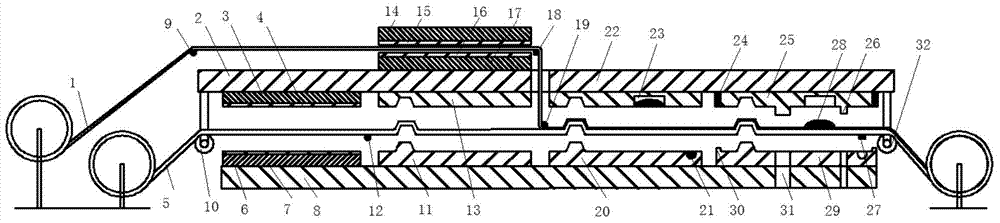

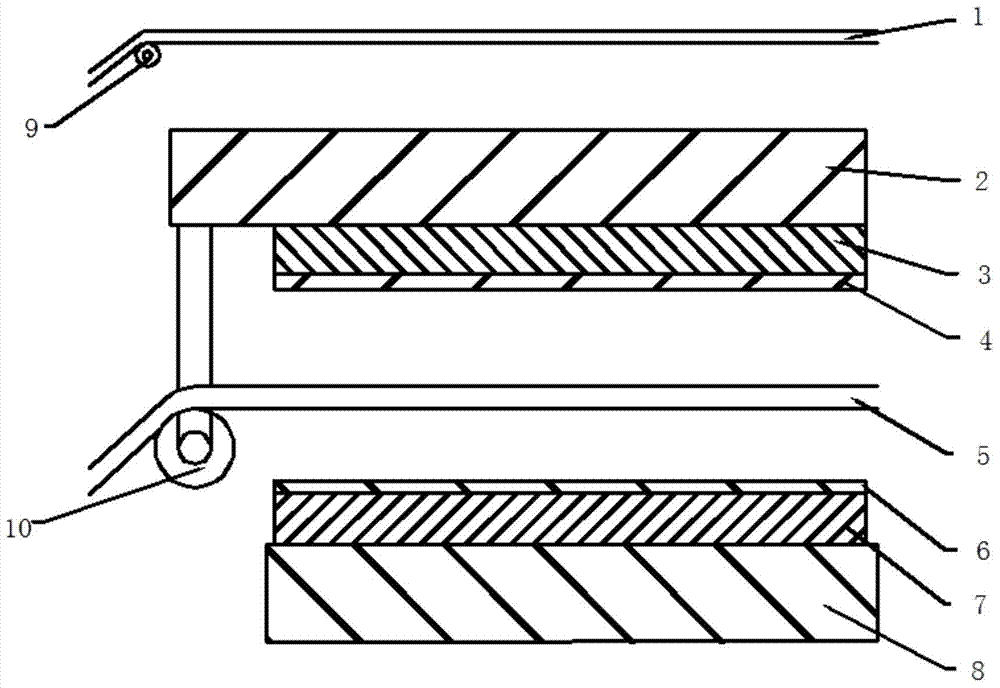

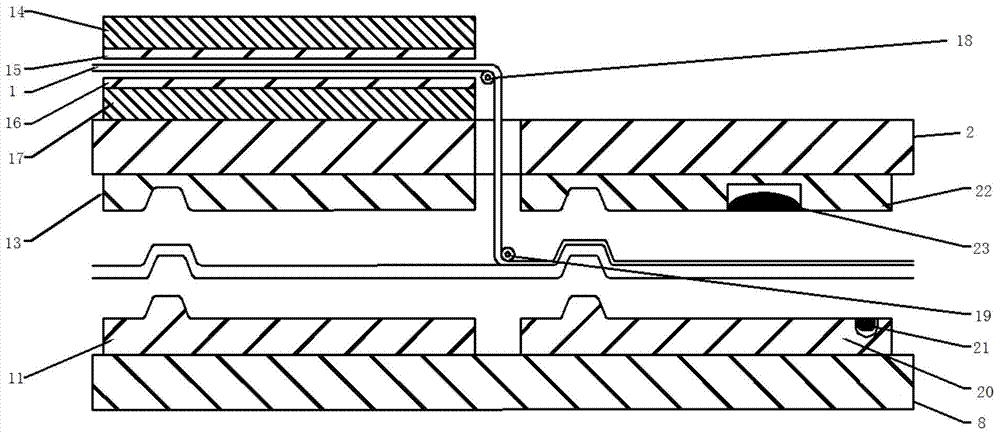

[0032] Such as Figure 1-Figure 4 As shown, a progressive molding device for a door natural fiber composite interior trim panel, including four stations arranged in sequence and continuous progressive surface layer fiber mat 1 and core layer fiber mat 5, the four stations There are upper mold base 2 and lower mold base 8 which can open and close the mold; Reciprocate up and down together.

[0033] The first station is provided with an upper heating plate 4 on the core layer and a lower heating plate 6 on the core layer, the upper heating plate 4 on the core layer is fixed on the upper mold base 2 through the backing plate 3 on the core layer, and the lower heating plate 6 on the core layer Fixed on the lower mold base 8 by the lower backing plate 7 of the core layer; the wound core fiber mat 5 is horizontally stepped onto the upper core layer heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com