Printing and die-cutting machine of protective film and production process thereof

A production process and protective film technology, which is applied in the field of protective film printing cutting machine and its production process, can solve the problems of double-sided adhesive bonding that cannot be completed automatically, process loss, and incomplete glue dots, etc., so as to prevent bad glue pulling Phenomenon, preventing poor stretching, and improving the effect of lack of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

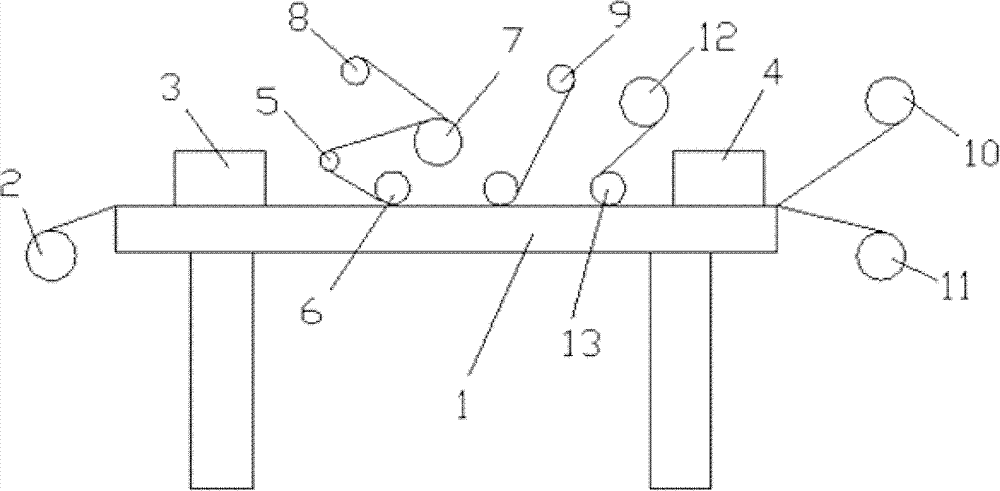

[0032] Such as figure 1 As shown, a protective film printing chopping machine includes a machine 1 and a release paper feed roller 2 and a receiving roller 11 arranged at both ends of the machine 1, and the machine 1 is also provided with water offset printing The device 3 and the chopping seat 4, the first waste discharge roller 10 is arranged above the receiving roller 11, and the first laminating roller 6, double The surface rubber feeding roller 7, the second coating roller 13 and the surface material feeding roller 12, the front and rear of the double-sided rubber feeding roller 7 are respectively provided with a second waste discharge roller 8 and a third waste discharge roller 9.

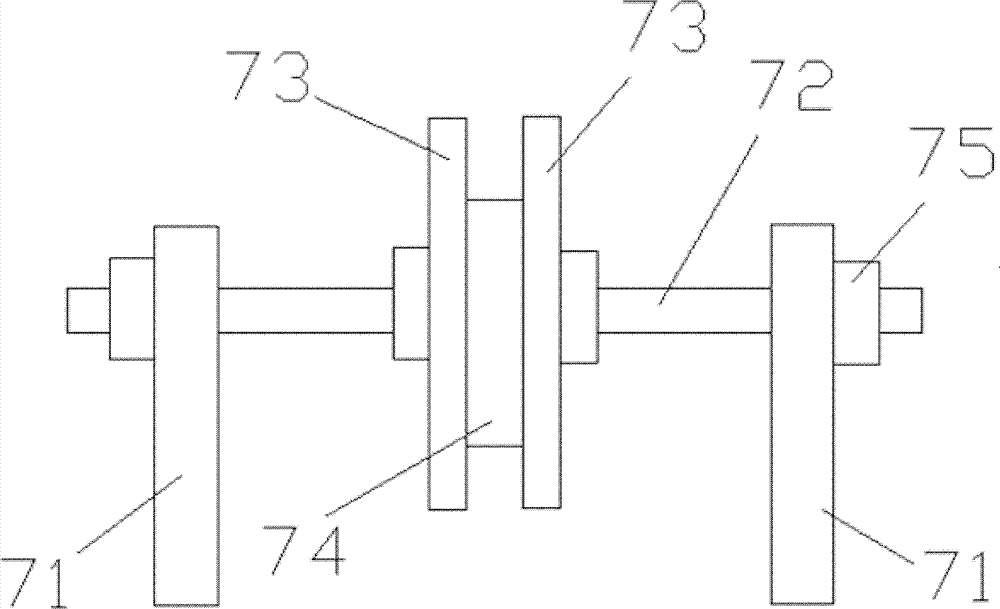

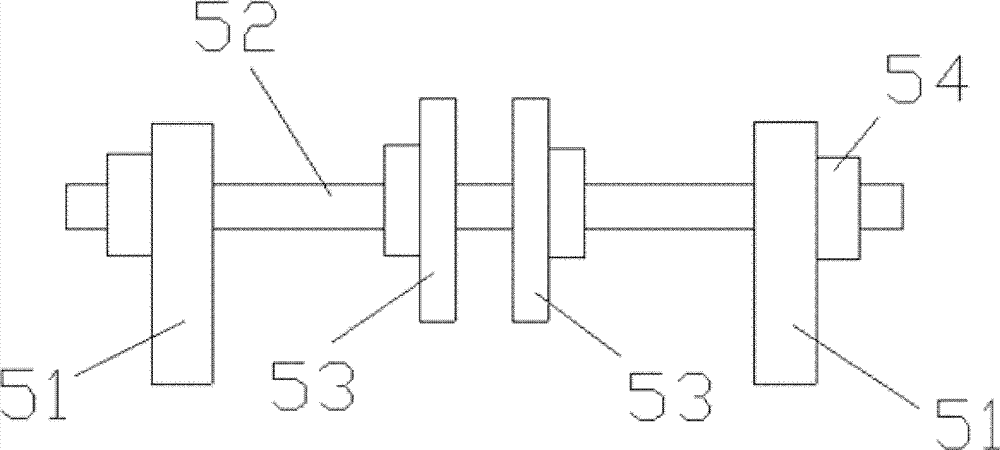

[0033] Such as Figure 4 As shown, the first coating roller 6 includes two segmented tension shafts 63, and the two segmented tension shafts 63 are fixed between the two first colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com