Walking mechanism of sampling robot

A walking mechanism and robot technology, which is applied in motor vehicles, tracked vehicles, transportation and packaging, etc., can solve the problems of difficult conditions, tedious sampling work, and less research on sampling robots, so as to achieve large-span and high platform crossing, easy The effect of the long-span high platform crossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

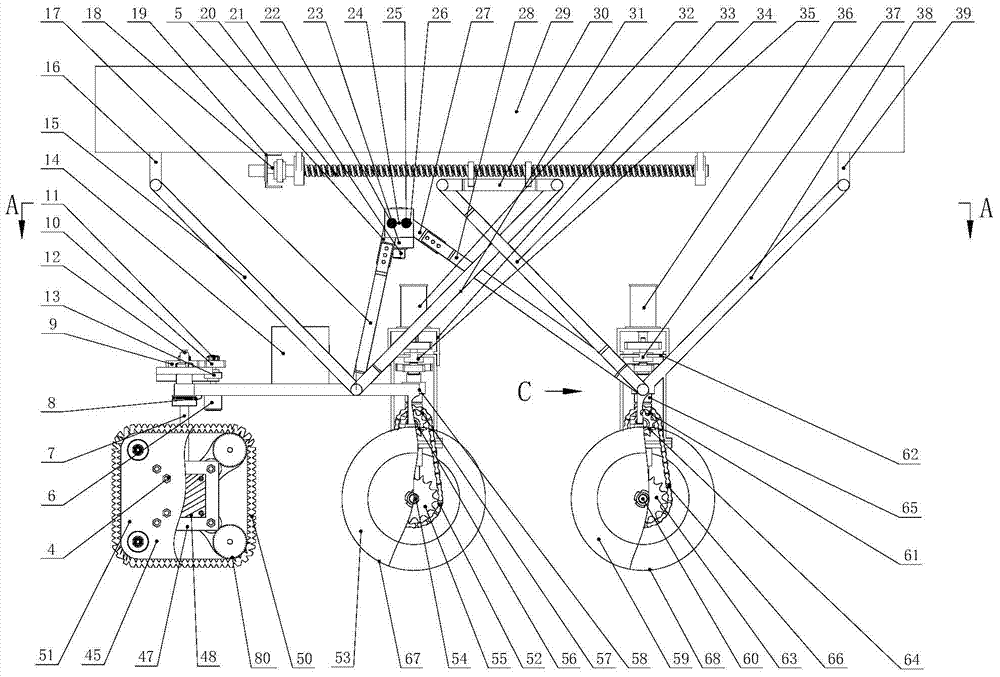

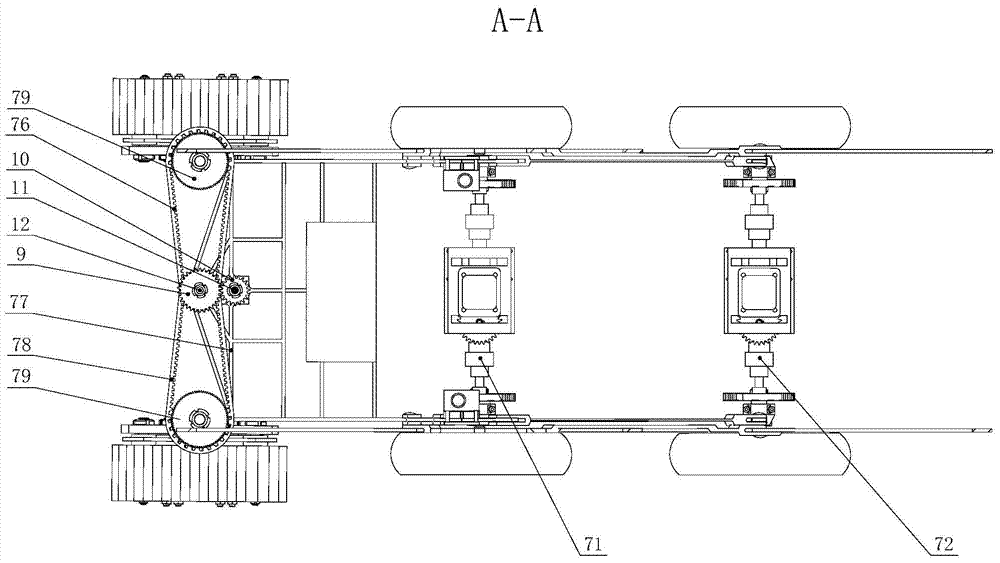

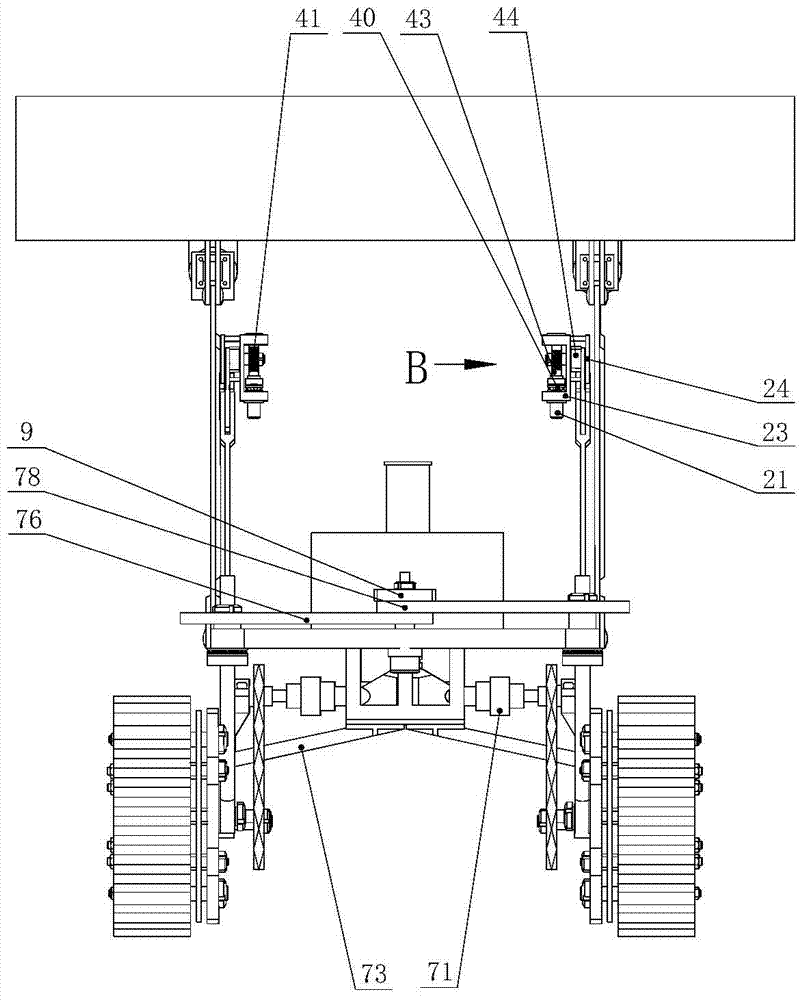

[0043] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0044] refer to Figure 1 to Figure 8 As shown, the sampling robot walking mechanism of the present invention includes a balance unit and a moving unit of the storage platform, wherein,

[0045] 1) The storage table balance unit is composed of a storage table 29, a connecting rod mechanism, a screw 20, and a screw motor 18,

[0046] The bottom of described object stand 29 is fixedly provided with two groups of front braces 16, rear brace 39, and two groups of front braces 16, rear brace 39 are symmetrically arranged on the four corners of object stand 29 ( figure 1 The left side of the paper is the front, the right side is the back, the viewer is the left side, and the paper is the right side);

[0047] Described link mechanism comprises two groups, is respectively arranged on the both sides of object table 29 (that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com