Fully automatic multi-functional material sorting pillow packaging machine

A pillow packaging machine, multi-functional technology, applied in multiple packaging, packaging, transportation and packaging, etc., can solve the problems of high installation and production costs, complicated electrical procedures, cumbersome equipment installation, etc., to achieve low installation and manufacturing costs, The electrical program is simple and the effect of simplifying manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

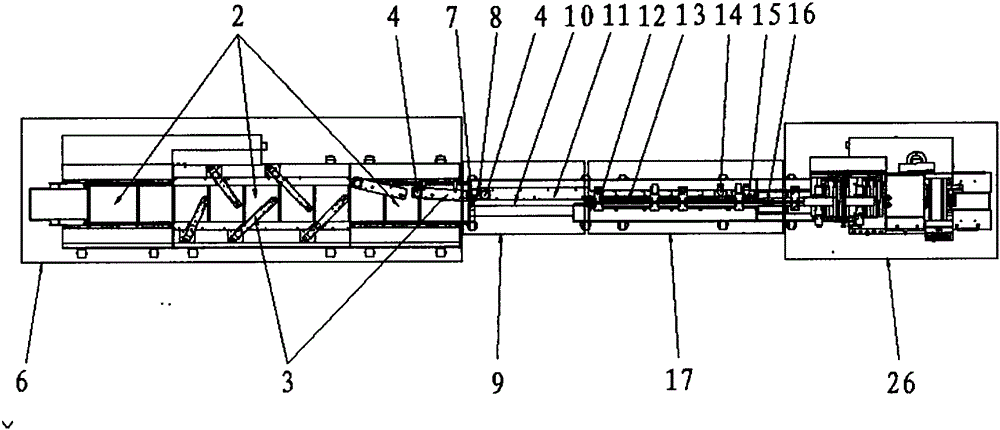

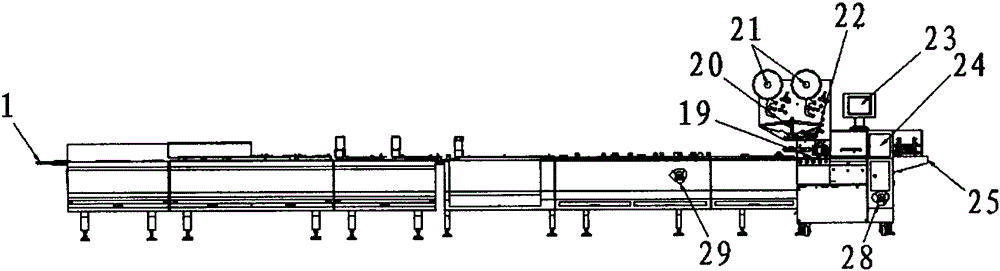

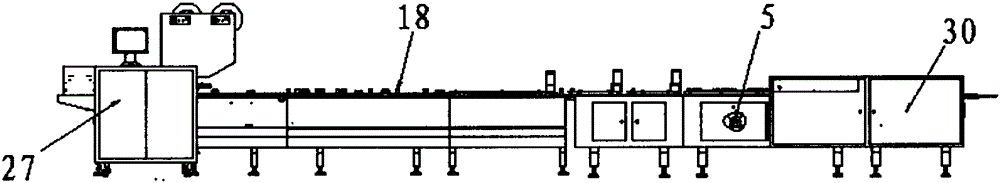

[0031] Such as Figure 1-7 As shown, the fully automatic multi-functional material sorting pillow packaging machine includes an automatic packing material sorting part 6 arranged at the front end, and an irregular material automatic screening part 9 and automatic packing material filling positions are arranged at equal intervals in the middle section from front to back. Part 17, the end is provided with an outlet part 26 of the packaged product into a bag;

[0032] Packing automatic sorting part 6, this part includes the packing material feed inlet 1. A finishing conveyor belt flat belt 2 is arranged inside the feed inlet 1, and finishing conveyor belt side belts are arranged on both sides of the finishing convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com