AGV self-propelled unloading transport cart

A transport vehicle, self-propelled technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of increased production costs, large equipment volume, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

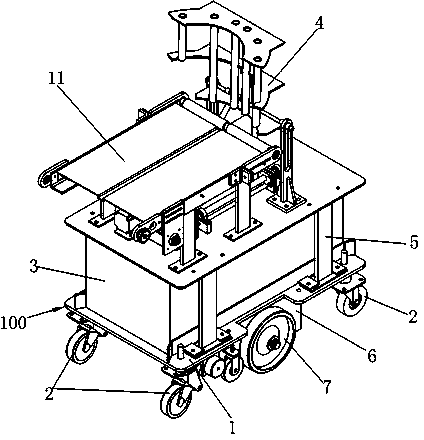

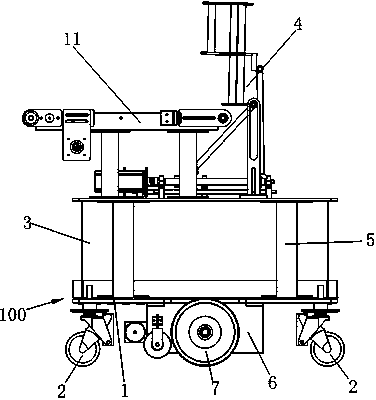

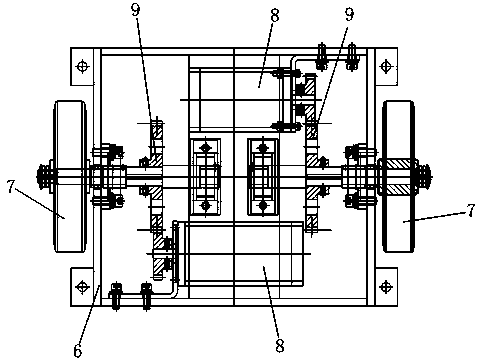

[0029] like Figure 1~4 As shown, the present invention comprises car body 100, battery, control system and electromagnetic guidance device, and car body 100 comprises chassis 1 and vehicle frame 5, and control box 3 is installed on the inner side of vehicle frame 5 above chassis 1, and battery, control system and The electromagnetic guidance device is arranged in the control box 3 . Two universal wheels 2 are respectively installed at the front and rear ends of the chassis 1, and the driving wheel box 6 is installed below the middle part of the chassis 1, and two coaxial driving wheels 7 are respectively arranged on both sides of the driving wheel box 6, and the two driving wheel boxes 7 are respectively connected with independent driving mechanisms, that is to say, the two driving wheels 7 have their own driving mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com