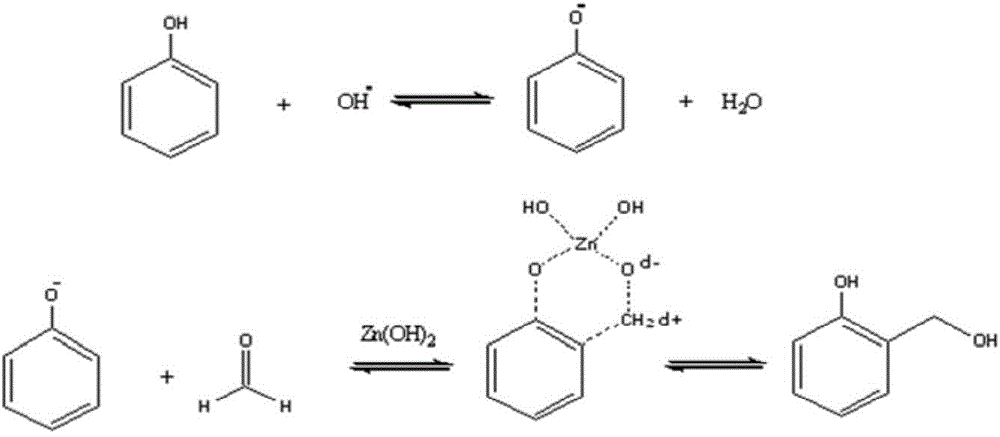

High-ortho-position phenol-formaldehyde resin prepolymer and preparation method thereof

A technology of phenolic resin prepolymerization and high ortho position, which is applied in the fields of aldehyde/ketone condensation polymer adhesives, manufacturing tools, casting molding equipment, etc., and can solve the problem of limiting the application of high ortho phenolic resin and the methylol content of phenolic resin Low, to be developed and other issues, to achieve the effect of high adjacent to bit ratio, high positioning effect, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

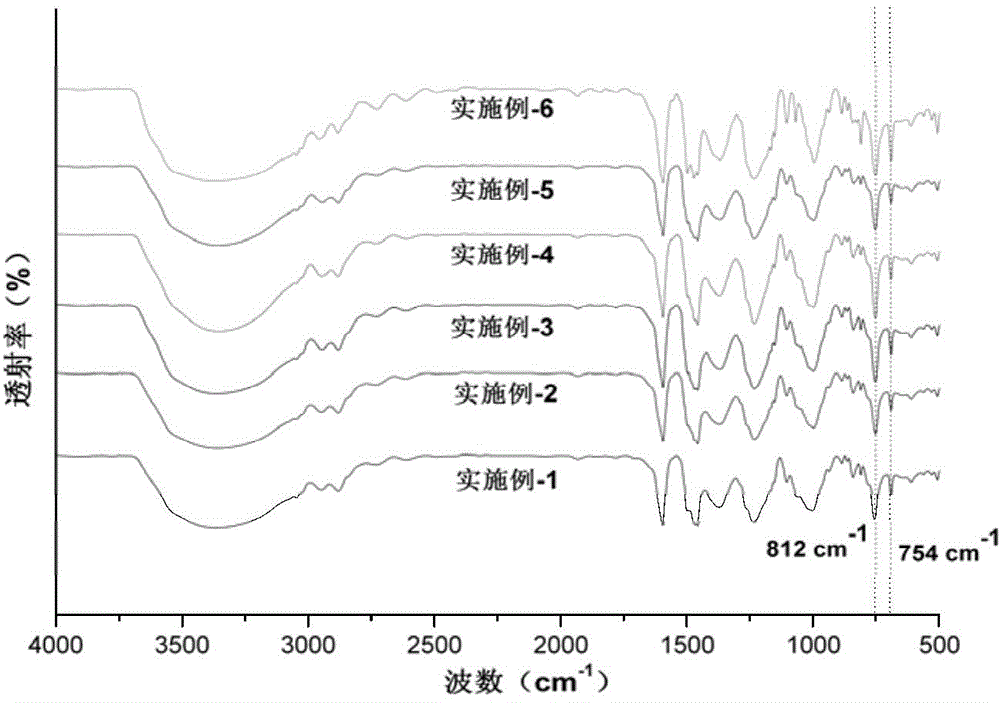

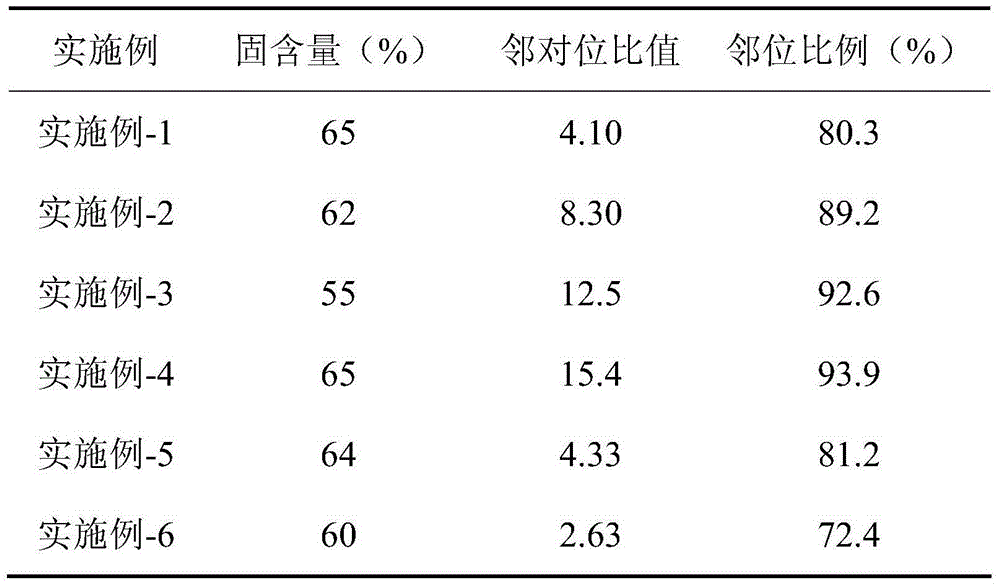

[0031] In a 500mL four-neck flask equipped with a thermometer and a reflux condenser, add 119.7g of formaldehyde solution (40% by mass fraction), mechanically stir, add 100.0g of phenol, and the molar ratio of phenol to formaldehyde is 1:1.5. After dissolving, add 0.5g zinc acetate, wherein zinc acetate is 0.5% of phenol mass, after zinc acetate dissolves completely, add catalyst 0.2g sodium hydroxide, wherein the amount of sodium hydroxide is 0.2% of phenol mass, stir and heat to 45 ℃ and kept at this temperature for 0.5 hours, heated to 100 ℃ and refluxed for 6 hours, cooled to 60 ℃ and dehydrated to a solid content of 65%. The prepared phenolic resin prepolymer had an ortho-to-para ratio of 4.1 .

Embodiment -2

[0033] In a 500mL four-neck flask equipped with a thermometer and a reflux condenser, add 109.4g of formaldehyde solution (mass fraction is 35%), mechanically stir, add 100.0g of phenol, the molar ratio of phenol to formaldehyde is 1:1.2, until the phenol is completely After dissolving, add 1.0g zinc acetate, wherein zinc acetate is 1.0% of phenol mass, after zinc acetate dissolves completely, add catalyst 0.4g sodium hydroxide, wherein the amount of sodium hydroxide is 0.4% of phenol mass, stir and heat to 50 ℃ and kept at this temperature for 0.75 hours, heated to 85 ℃ and refluxed for 5 hours, cooled to 50 ℃ and dehydrated to a solid content of 62%. The prepared phenolic resin prepolymer had an ortho-to-para ratio of 8.3 .

Embodiment -3

[0035] In a 500mL four-necked flask equipped with a thermometer and a reflux condenser, add 86.2g of formaldehyde solution (mass fraction is 37%), mechanically stir, add 100.0g of phenol, the molar ratio of phenol to formaldehyde is 1:1.0, until the phenol is completely After dissolving, add 2.0g zinc acetate, wherein zinc acetate is 2.0% of phenol mass, after zinc acetate dissolves completely, add catalyst 0.8g sodium hydroxide, wherein sodium hydroxide consumption is 0.8% of phenol mass, stir and heat to 60 ℃ and kept at this temperature for 1 hour, heated to 90 ℃ and refluxed for 6 hours, cooled to 45 ℃ and dehydrated to a solid content of 55%, the prepared phenolic resin prepolymer had an ortho-to-para ratio of 12.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap