Oily purple/blue paste and preparation method thereof

A blue, oily technology, applied in the direction of pigment slurry, etc., can solve the problems of poor storage stability and dilution stability, floating color and blooming, etc., to achieve the effect of blooming, helping to disperse and prevent paint floating color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

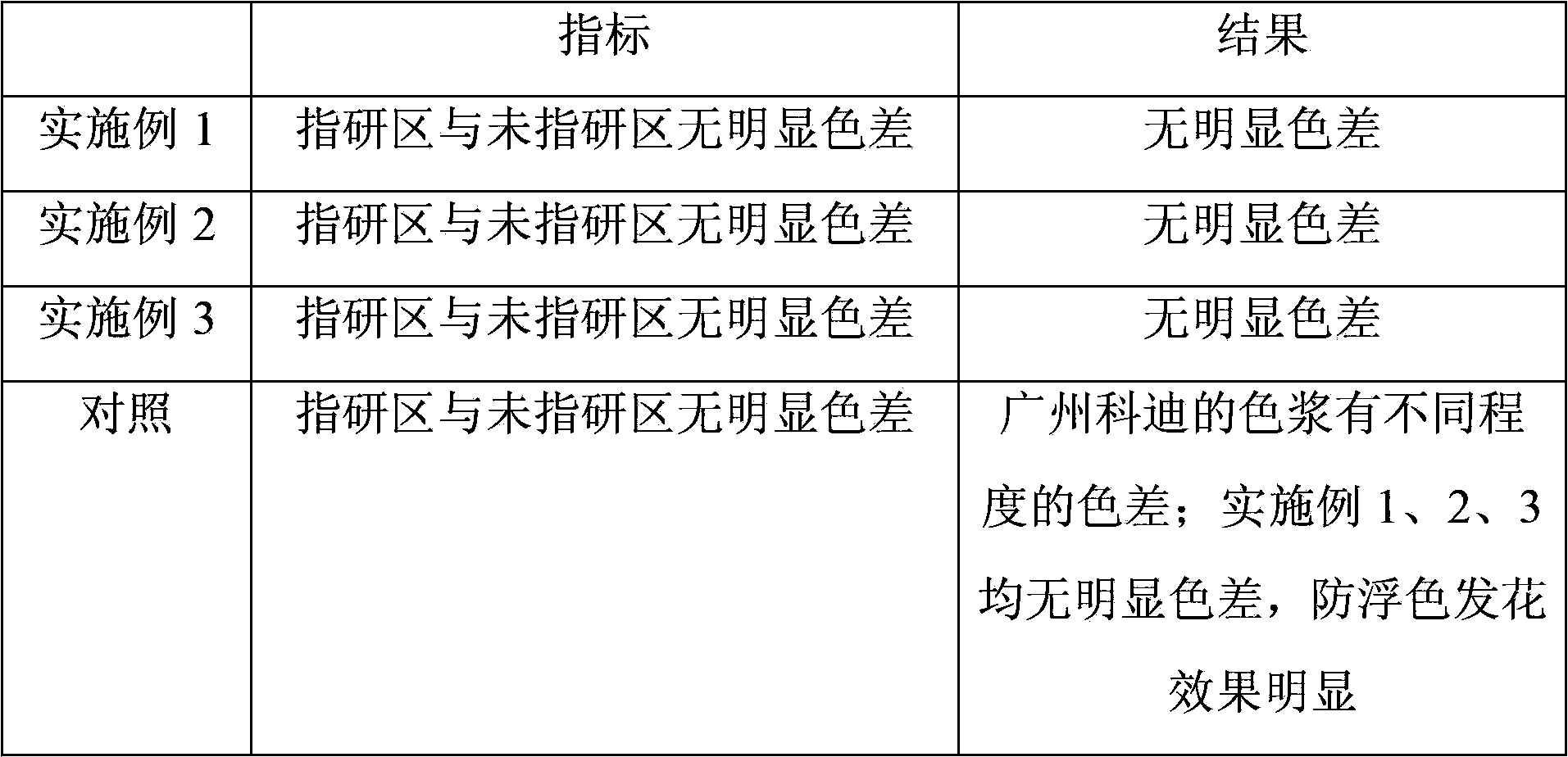

Examples

Embodiment 1

[0024] An oily purple pulp formulation (weight), oily permanent purple pulp.

[0025] The components and weight ratio of oily permanent purple paste are as follows:

[0026] 40 kg of alkyd resin, 25 kg of propylene glycol methyl ether acetate, 0.1 kg of anti-skinning agent, 4 kg of dispersant, 0.9 kg of synergistic dispersant, 20 kg of permanent purple powder, 10 kg of butyl acetate.

[0027] Preparation:

[0028] (1) The conventional physical mixing method is the first, that is, various materials are mixed in proportion and dispersed at a high speed of 1800rpm to prepare a paste-like product.

[0029] (2) Then pass through a sand mill to a fineness of 15 μm to obtain 100 kg of qualified products.

Embodiment 2

[0031] An oily blue paste formulation (by weight): oily phthalocyanine blue paste.

[0032] The components and weight ratio of oily phthalocyanine blue paste are as follows:

[0033] 55 kg of alkyd resin, 15 kg of propylene glycol methyl ether acetate, 0.1 kg of anti-skinning agent, 4 kg of dispersant, 1.9 kg of synergistic dispersant, 20 kg of phthalocyanine blue powder, and 5 kg of butyl acetate.

[0034] Preparation:

[0035] (1) The conventional physical mixing method is the first, that is, various materials are mixed in proportion and dispersed at a high speed of 2000rpm to prepare a paste-like product.

[0036] (2) Then pass through a sand mill to a fineness of 15 μm to obtain 100 kg of qualified products.

Embodiment 3

[0038] An oily purple pulp formulation (weight), oily permanent purple pulp.

[0039] The components and weight ratio of oily permanent purple paste are as follows:

[0040] 60 kg of alkyd resin, 15 kg of propylene glycol methyl ether acetate, 0.1 kg of anti-skinning agent, 4 kg of dispersant, 2.9 kg of synergistic dispersant, 11 kg of permanent purple powder, and 9 kg of butyl acetate.

[0041] Preparation:

[0042] (1) The conventional physical mixing method is the first, that is, various materials are mixed in proportion and dispersed at a high speed of 1800rpm to prepare a paste-like product.

[0043] (2) Then pass through a sand mill to a fineness of 15 μm to obtain 100 kg of qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com