Preparation method of rapid repairing coating for wind turbine blade

A wind turbine blade, fast technology, applied in the field of coatings, can solve the problems of short construction time, low adhesion, and increased efficiency of polyurea coatings, and achieve the improvement of physical and mechanical properties and construction properties, impact strength, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

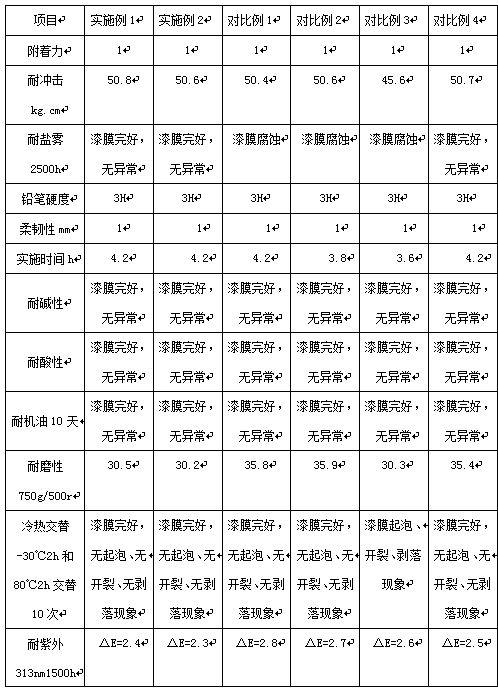

Examples

Embodiment 1

[0021] A method for preparing a quick repair coating for wind turbine blades, comprising the following steps:

[0022] (1) In parts by weight, first inject 85 parts of deionized water into the reactor, add 0.05 parts of initiator, then pass 90 mL / min nitrogen gas into the water for 25 minutes, then add 0.1 part of compound emulsifier into it, and stir Under the conditions, a mixture of 23 parts of dicyclopentadiene dioxide, 31 parts of vinyl ester resin, 8 parts of butyl acrylate and 14 parts of methyl methacrylate was dropped into the reactor, and the polymerization reaction was carried out in the reactor, stirring After 20 minutes, transfer to a constant temperature water bath at 80°C and react for 2 hours, then demulsify, precipitate, and dry to obtain interpenetrating latex particles; (2) 40 parts of vinyl ester resin, 31 parts of interpenetrating latex particles, 6 parts of pigments, Add 6 parts of additives into the paint mixing tank in turn, disperse at high speed for 3...

Embodiment 2

[0024](1) In parts by weight, first inject 80 parts of deionized water into the reactor, add 0.02 parts of initiator, then pass 80 mL / min nitrogen gas into the water for 20 minutes, then add 0.02 parts of compound emulsifier into it, and stir Under the conditions, a mixture of 12 parts of dicyclopentadiene dioxide, 24 parts of Novolac vinyl ester resin, 5 parts of butyl acrylate and 12 parts of methyl methacrylate was dropped into the reactor, and the polymerization reaction was carried out in the reactor. After stirring for 10 minutes, transfer to a constant temperature water bath at 75°C and react for 2 hours, then demulsify, precipitate, and dry to obtain interpenetrating latex particles; (2) 35 parts of Novolac vinyl ester resin, 24 parts of interpenetrating latex particles, 4 parts of pigment, Add 4 parts of rheological additives into the paint mixing tank in turn, disperse at high speed for 30 minutes, and then grind and disperse to a fineness of 40 μm with a sand mill to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com