Sheath gas heatable focus electrospinning direct-writing nozzle device

An electrospinning direct-writing and heating technology, which is applied in the direction of spinneret assemblies, textiles and papermaking, fiber treatment, etc., can solve the problem of inability to effectively control the diameter and shape structure of solvent volatilized fibers, and the inability to adjust the solution channel and small hole at the same time. Axis, difficulty in nozzle simplification and integrated control, etc., to achieve the effect of suppressing the unstable movement of the jet, reducing the start-up voltage and injection maintenance voltage, and improving refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

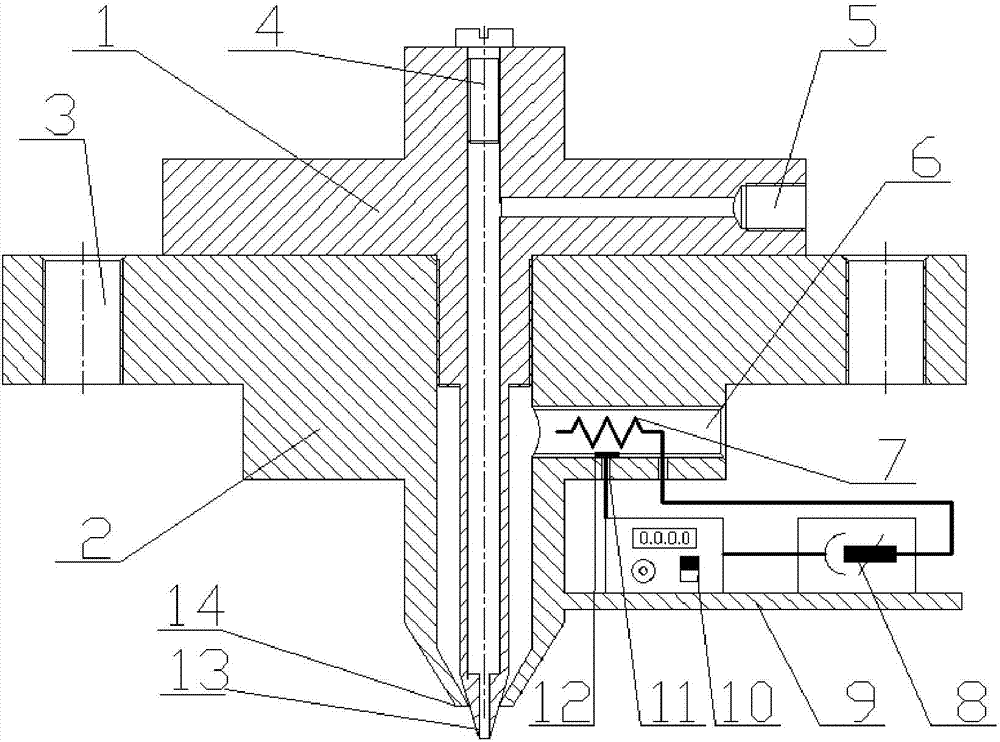

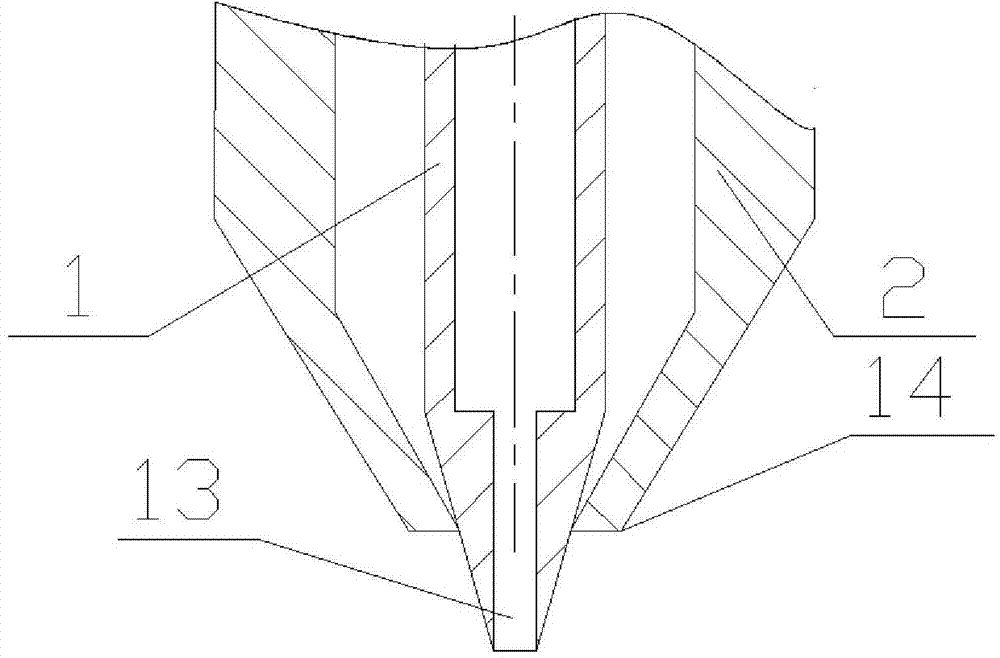

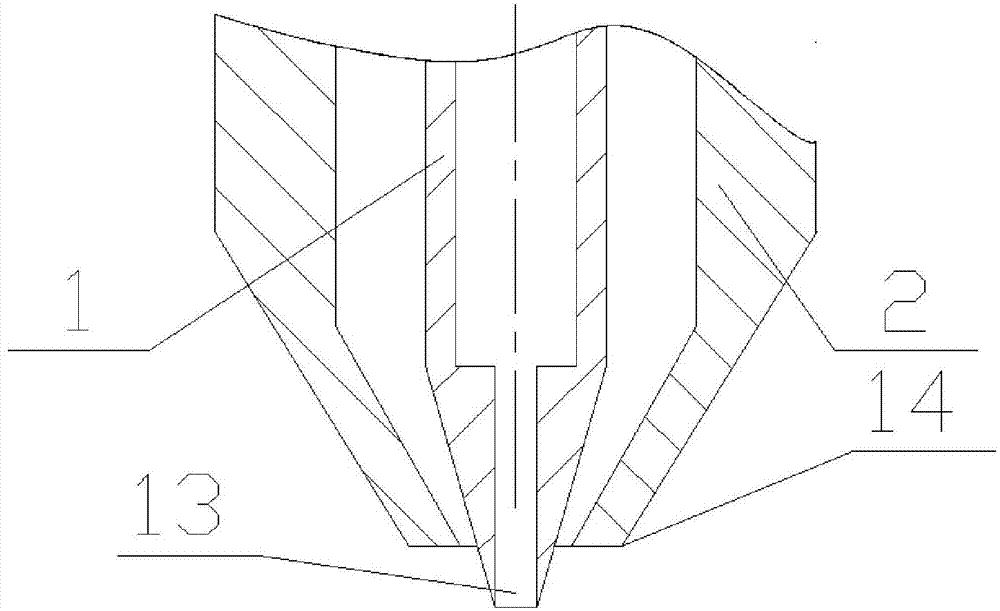

[0016] see Figure 1~3 , The embodiment of the present invention includes a liquid inlet nozzle seat 1, an air inlet box body 2, a terminal post 4, an electric heating element 7, a relay 8, a numerically controlled temperature unit 10, and a temperature measuring element 12.

[0017] Both the liquid inlet nozzle seat 1 and the air inlet box body 2 are provided with a central through hole, and are arranged coaxially; On the upper end surface of the box body 2, the lower part of the liquid inlet nozzle seat 1 extends into the central through hole of the air inlet box body 2, the terminal post 4 is arranged on the liquid inlet nozzle seat 1, and the liquid inlet nozzle seat 1 is provided with a radial liquid inlet hole 5. The lower end of the liquid inlet nozzle seat 1 is provided with an axial nozzle part 13; the air intake box body 2 is provided with at least two axial connection through holes 3 for external installation, and the air intake box body 2 is provided with a radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com