A kind of preparation method of seamless bonding polyurethane synthetic leather

A polyurethane and synthetic leather technology, applied in chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc., can solve the problems of limited application scope, poor setting effect, leather surface shrinkage, etc., to achieve strong functionality and wearability. Lightweight and smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

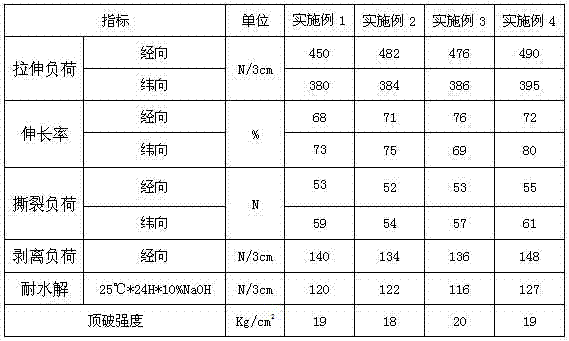

Examples

Embodiment 1

[0039] 1. Preparation of polyurethane slurry

[0040] Preparation of polyurethane impregnating material:

[0041] Dimethylformamide DMF 240 kg

[0042] Water repellant F-3D 1kg

[0043] Polyester polyurethane resin SW-4008 100kg

[0044] Color paste BLPN-560 15kg

[0045] Preparation of polyurethane coating materials:

[0046] Dimethylformamide DMF 150kg

[0047] Hole regulator HY-607 1kg

[0048] Packing 15kg

[0049] Polyether polyurethane resin SW-4040RHA 120kg

[0050] Polyether polyurethane resin SW-5060RH 80kg

[0051] Polycarbonate polyurethane resin SW-410PC 50kg

[0052] Color paste BLPN-560 5kg

[0053] 2. Preparation of semi-finished products of buffed synthetic leather

[0054] Immerse the high-physical composite base fabric blended with thin woven fabric and non-woven fabric in polyurethane impregnation solution, squeeze the rollers, control according to the thickness of the cloth base, and then pre-coagulate (pre-coagulation conditions are temperature ...

Embodiment 2

[0057] 1. Preparation of polyurethane slurry

[0058] Preparation of polyurethane impregnating material:

[0059] Dimethylformamide DMF 200 kg

[0060]Water repellant F-3D 1kg

[0061] Polyester polyurethane resin SW-4008 100kg

[0062] Color paste BLPN-560 15kg

[0063] Preparation of polyurethane coating materials:

[0064] Dimethylformamide DMF 120kg

[0065] Hole regulator HY-607 1kg

[0066] Packing 15kg

[0067] Polyether polyurethane resin SW-4040RHA 110kg

[0068] Polyether polyurethane resin SW-5060RH 100kg

[0069] Polycarbonate polyurethane resin SW-410PC 40kg

[0070] Color paste BLPN-560 5kg

[0071] 2. Preparation of semi-finished products of buffed synthetic leather

[0072] After the polyurethane slurry is filtered, it is coated on the woven surface of the base fabric, dipped and coated, and then placed in a coagulation tank to solidify, washed and dried to obtain a wet-process synthetic leather semi-finished product. The speed is 8 m / min, the thickn...

Embodiment 3

[0075] Preparation of polyurethane impregnating material:

[0076] Dimethylformamide DMF 500 kg

[0077] Water repellant F-3D 3kg

[0078] Polyester polyurethane resin SW-4008 200kg

[0079] Color paste BLPN-560 15kg

[0080] Preparation of polyurethane coating materials:

[0081] Dimethylformamide DMF 300kg

[0082] Hole regulator HY-607 1kg

[0083] Packing 10kg

[0084] Polyether polyurethane resin SW-4040RHA 50kg

[0085] Polyether polyurethane resin SW-5060RH 150kg

[0086] Polycarbonate polyurethane resin SW-410PC 100kg

[0087] Color paste BLPN-560 10kg

[0088] Other processes are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com