Mechanical seal device for nuclear power waste heat removal pump

A technology of mechanical sealing device and waste heat discharge pump, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem of high dimensional accuracy, poor mutual followability, and structural performance matching performance at the inlaid place. The overall performance of the fixed connection performance between the sleeve d and the shaft is not ideal, so as to achieve the effect of high sealing performance and high safety and reliability in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

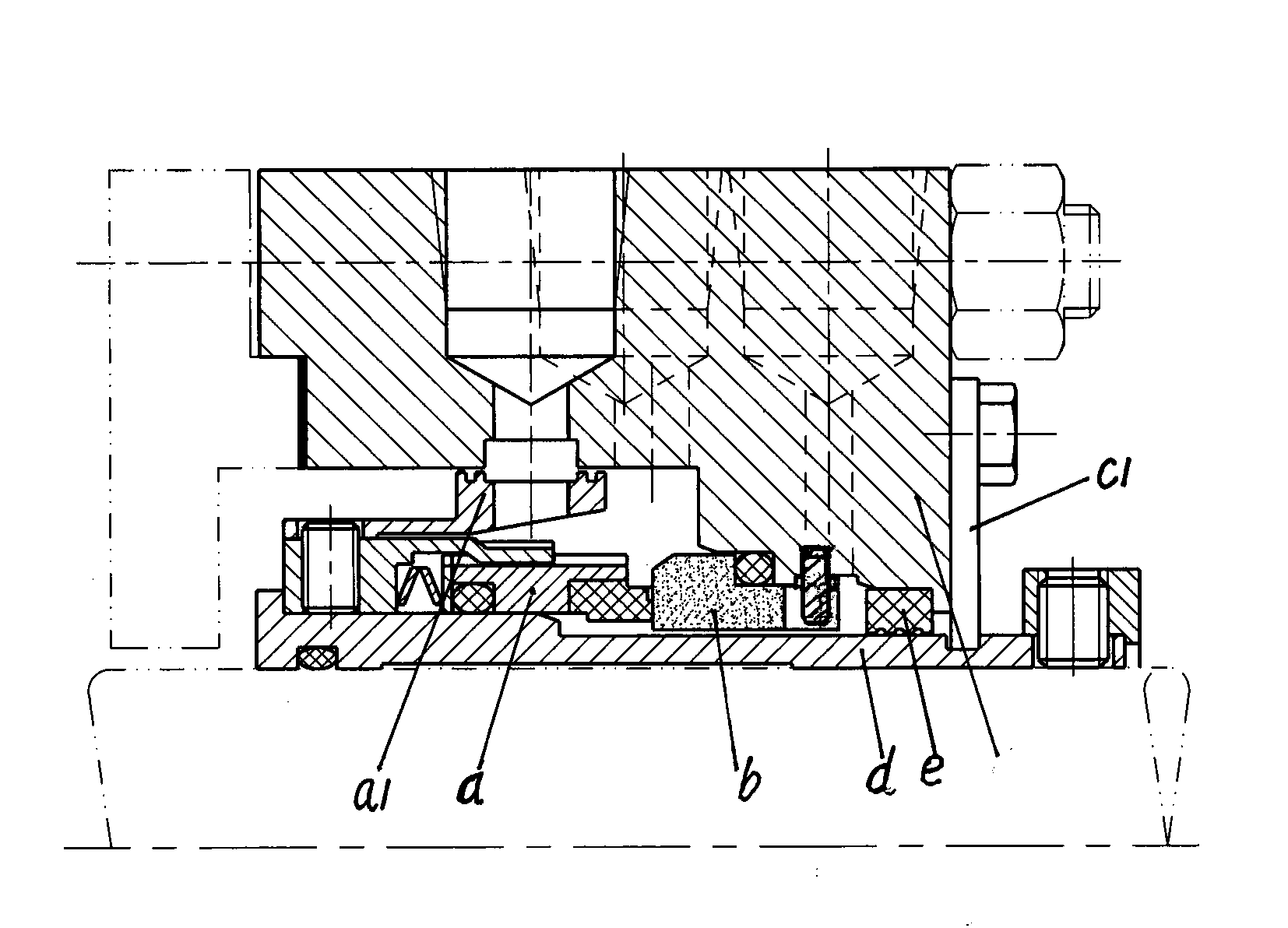

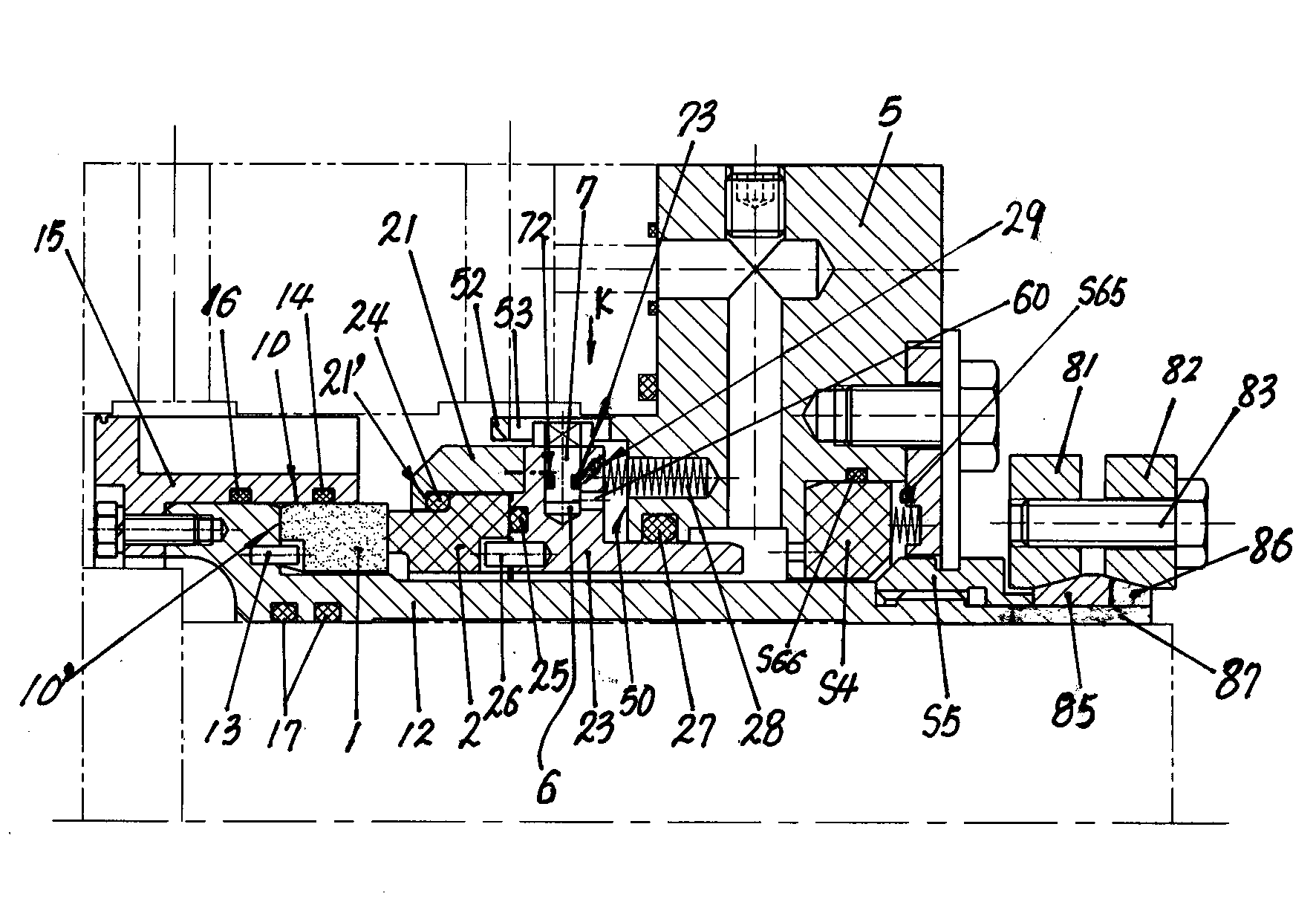

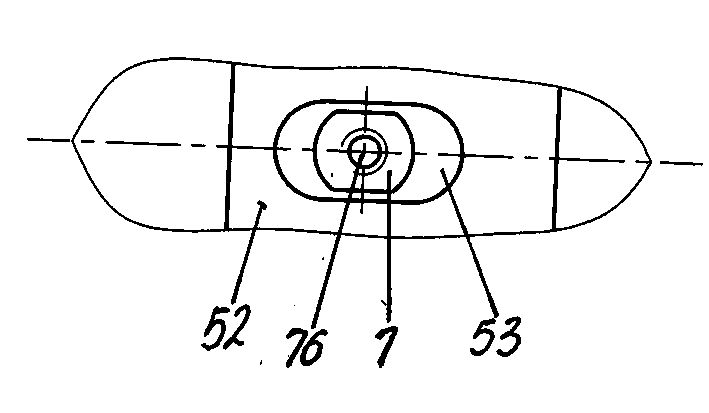

[0020] The invention comprises a moving ring assembly, a static ring assembly, a gland, and a water seal device on the gland, and is characterized in that the moving ring assembly consists of a moving ring 1, a shaft sleeve 12, a moving ring anti-rotation pin 13, and a moving ring auxiliary seal Ring 14, coolant pumping ring 15, pumping ring 15 sealing ring 16, shaft sleeve 12 sealing ring 17, the pumping ring 15 is fixedly connected with the rear end of the shaft sleeve 12 by bolts through the seam, and the pumping ring A sealing ring 16 is set between the inner ring surface of 15 and the mating surface of the outer ring of the shaft sleeve 12, and a notch seat 10 is provided on the shaft sleeve 12, and the moving ring 1 is installed in the notch seat 10 on the shaft sleeve 12. A moving ring auxiliary sealing ring 14 is arranged between the ring surface and the inner ring surface of the spigot seat 10; as shown in the embodiment of the drawings, the front end of the pumping ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com