In-situ protection construction method of pipeline above foundation pit

A construction method and pipeline technology, applied in the direction of pipeline protection, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems such as lack of mature technical solutions, and achieve the effect of avoiding settlement deformation and achieving in-situ protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

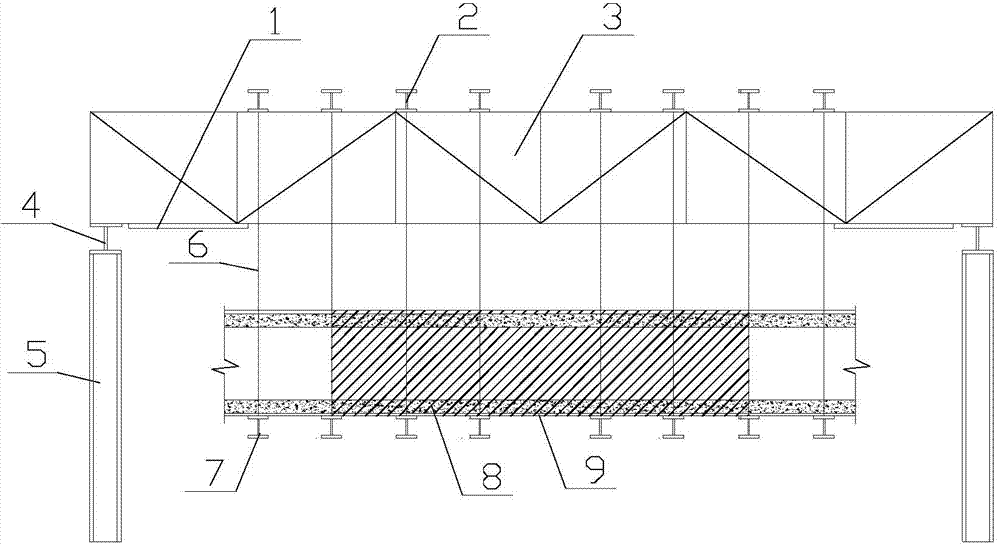

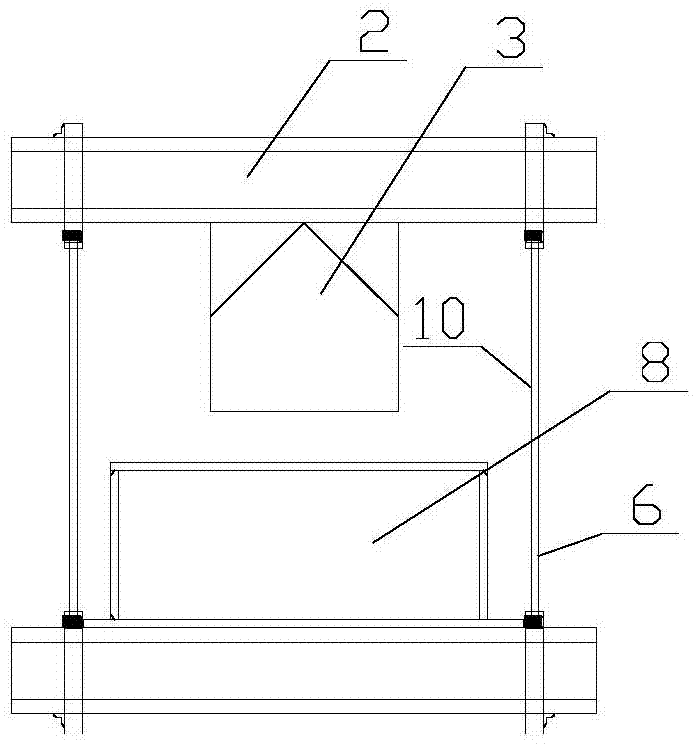

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

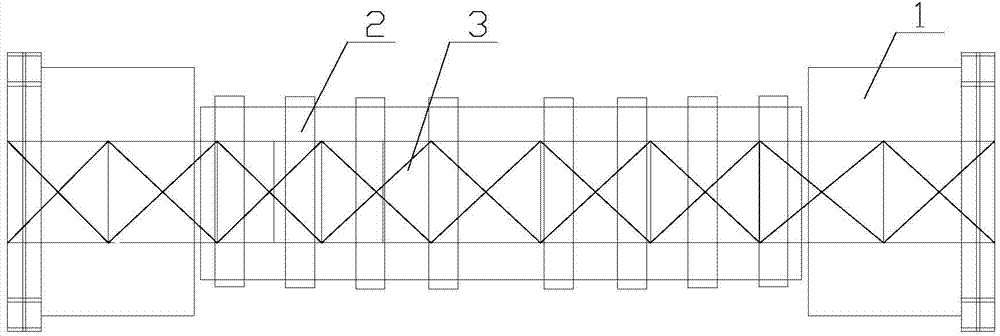

[0018] see Figure 1 ~ Figure 3 , an in-situ protection construction method for pipelines above a foundation pit, comprising the following steps:

[0019] 1) Destroy the pavement: before the construction of the foundation pit, remove the concrete pavement on the upper part of the pipeline box culvert 8;

[0020] Because the pipeline box culvert 8 is generally all buried below the ground, and its upper part is generally a concrete hardened pavement, the concrete pavement on the top of the pipeline box culvert 8 needs to be completely removed before construction, and cleared and transported to a designated location.

[0021] 2) Laying steel columns 5: according to the design position of the trusses 3, two steel columns 5 are punched correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com