Constant flow smoking machine

A constant flow rate, smoking machine technology, applied in the direction of sampling devices, etc., can solve the problems of low degree of automation, poor repeatability of experimental results, and the combustion environment is easily affected by the surrounding environment, to achieve high degree of automation, reduce impact, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

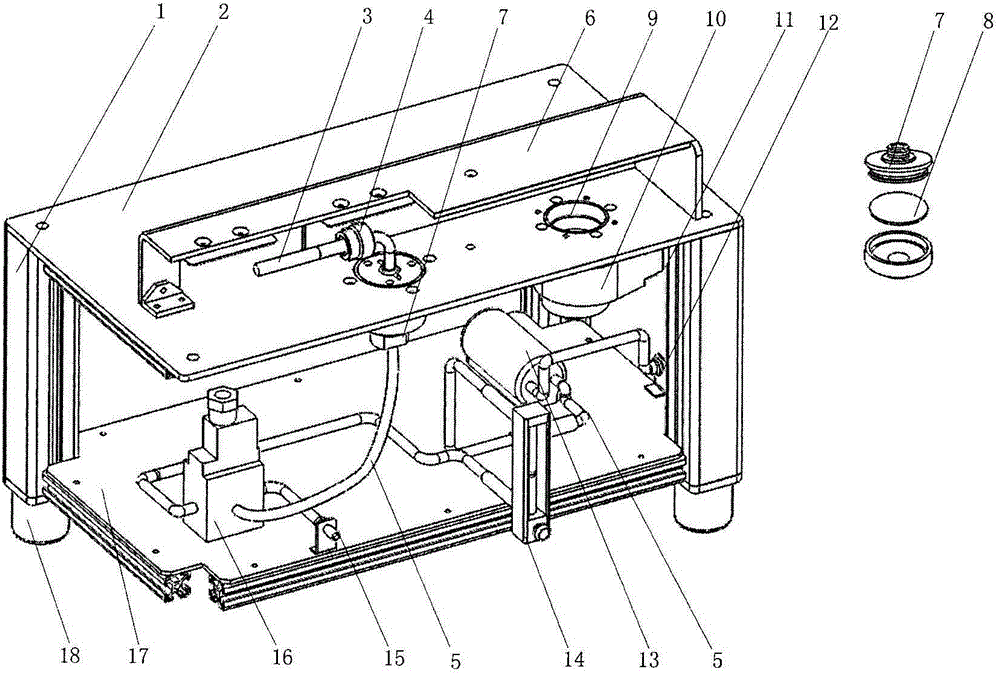

[0017] The present invention is described as follows to equipment composition and connection relation below in conjunction with accompanying drawing:

[0018] Such as figure 1 Shown: a constant flow rate smoking machine, including a cigarette holder 4 arranged on the upper panel 2, a total particulate matter collector 7 sequentially connected to the mainstream smoke pipe at the rear end of the cigarette holder, an electromagnetic converter Composed of a valve 16, a gas flow detection control device 14, a vacuum pump 13 and a mainstream smoke collection port 12, a plexiglass cover 6 for collecting sidestream smoke is installed on the upper panel 2, and on the upper panel located in the glass cover There is a side stream smoke outlet, which is equipped with a side stream smoke filter 9 and communicated with the side stream smoke fan 10 and the side stream smoke collection port 11; the total particulate matter trap 7 is equipped with a Cambridge 8, and embedded in the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com