Silicon material melting process monitoring method based on high-order singular value decomposition

A high-order singular value, melting process technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as inability to accurately and effectively monitor the melting of silicon materials, and achieve the effect of easy implementation and simple monitoring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

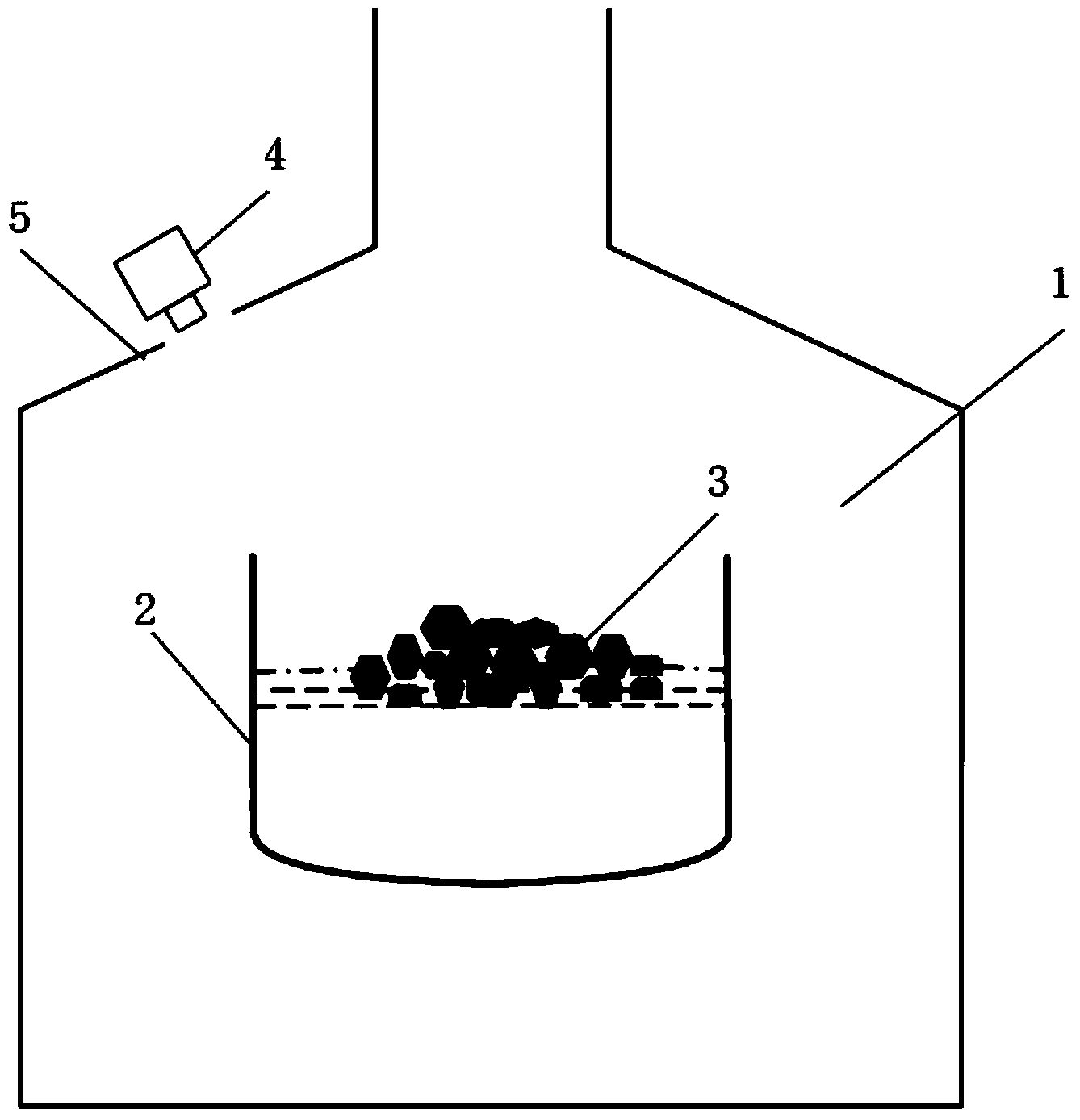

[0047] Step 1: If figure 1 As shown, a CCD camera is used to collect and store several images of the melting state of the silicon material at the current time t and the previous time, and the images are preprocessed by corresponding cropping and brightness transformation to obtain image data for detecting the melting state of the silicon material.

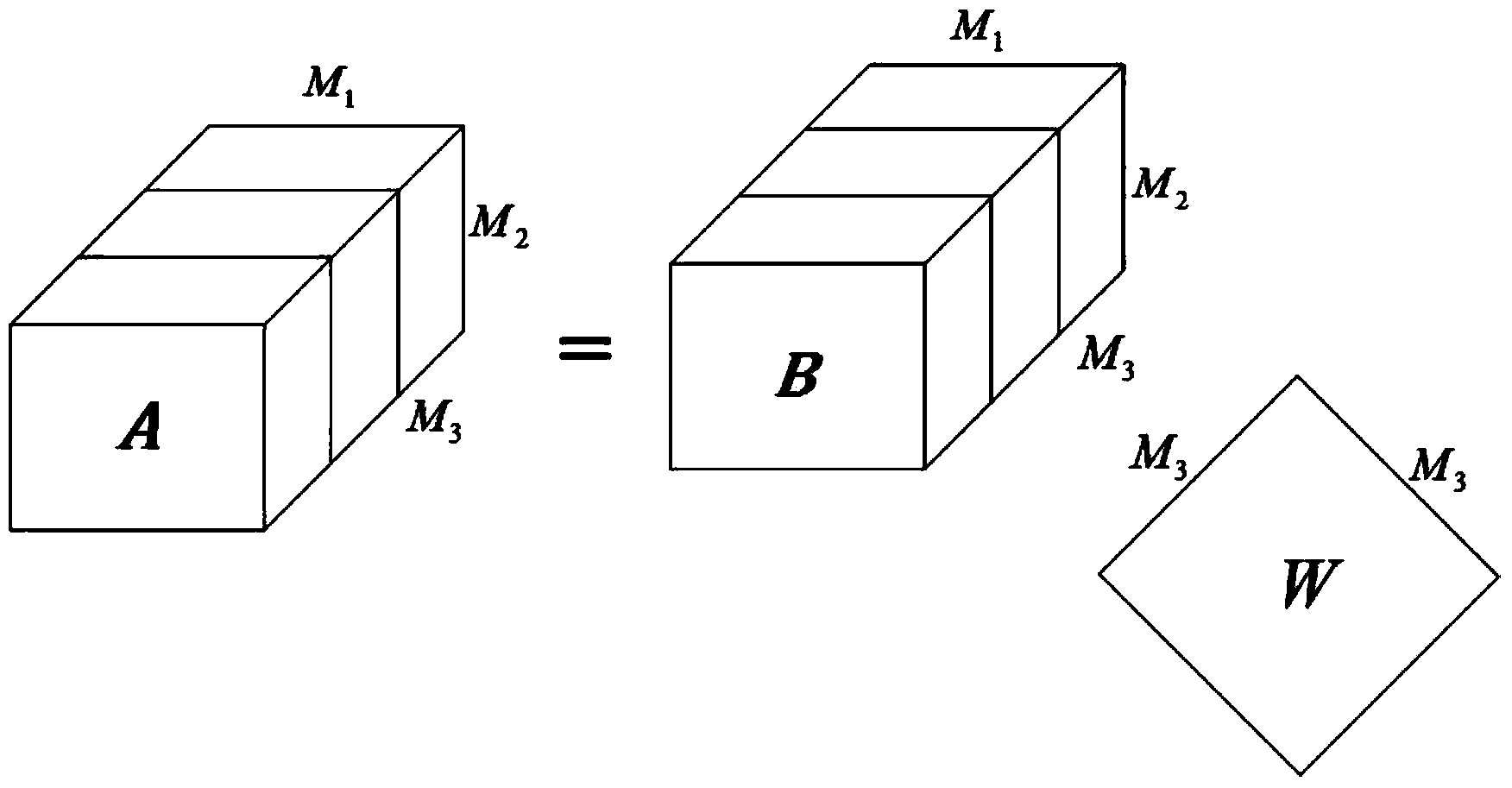

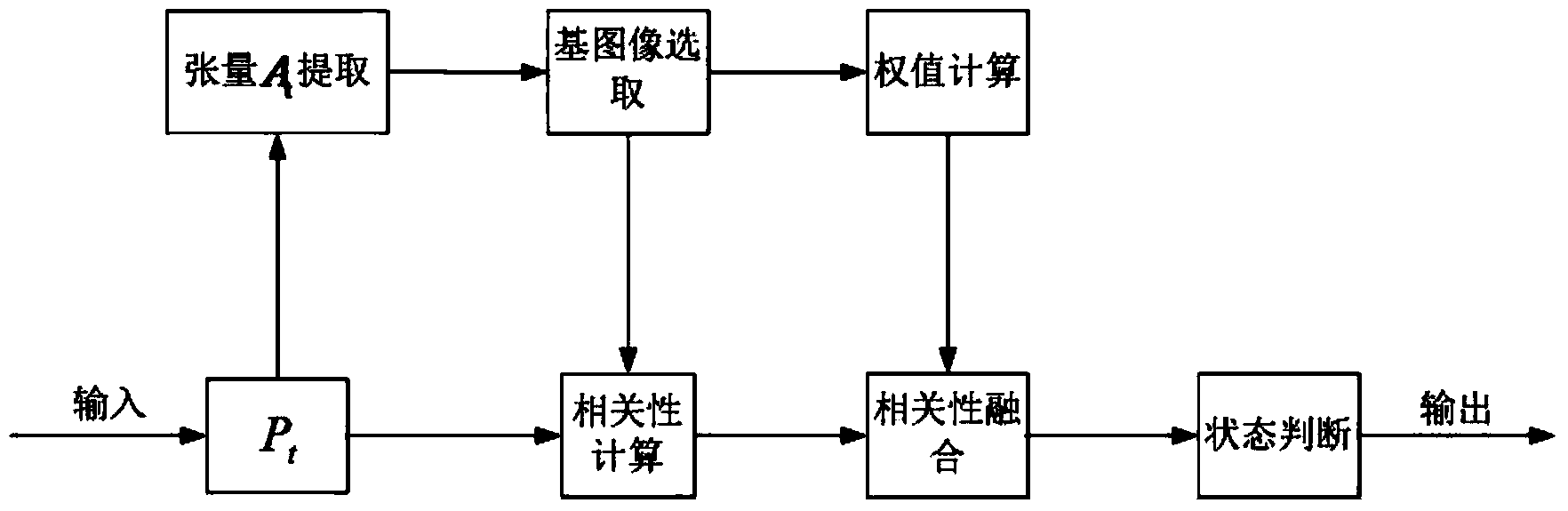

[0048] Step 2: The image P at the current moment t t and the image at the previous moment {P t-1 ,P t-2 ,...,P t-k} Calculate the dissimilarity d(P t ,P j ), and then passed with the set threshold {δ 1 ,…,δ k} to determine the image sequence at the previous moment for the detection of the melting state change of the silicon material, that is, when d(P t ,P j )≥δ j , the tensor A t Add one to the modulo-3 dimension of the image P j Put it in the corresponding position. Assuming that the size of the image is M×N, and the number of selected images is k, the third-order tensor A t The size of is M×N×k.

[0049] in, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com