High rigidity compound processing machine

A compound processing and high rigidity technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of weak rigidity, low rigidity, long distance, etc., to reduce shaking, improve overall rigidity, and improve processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

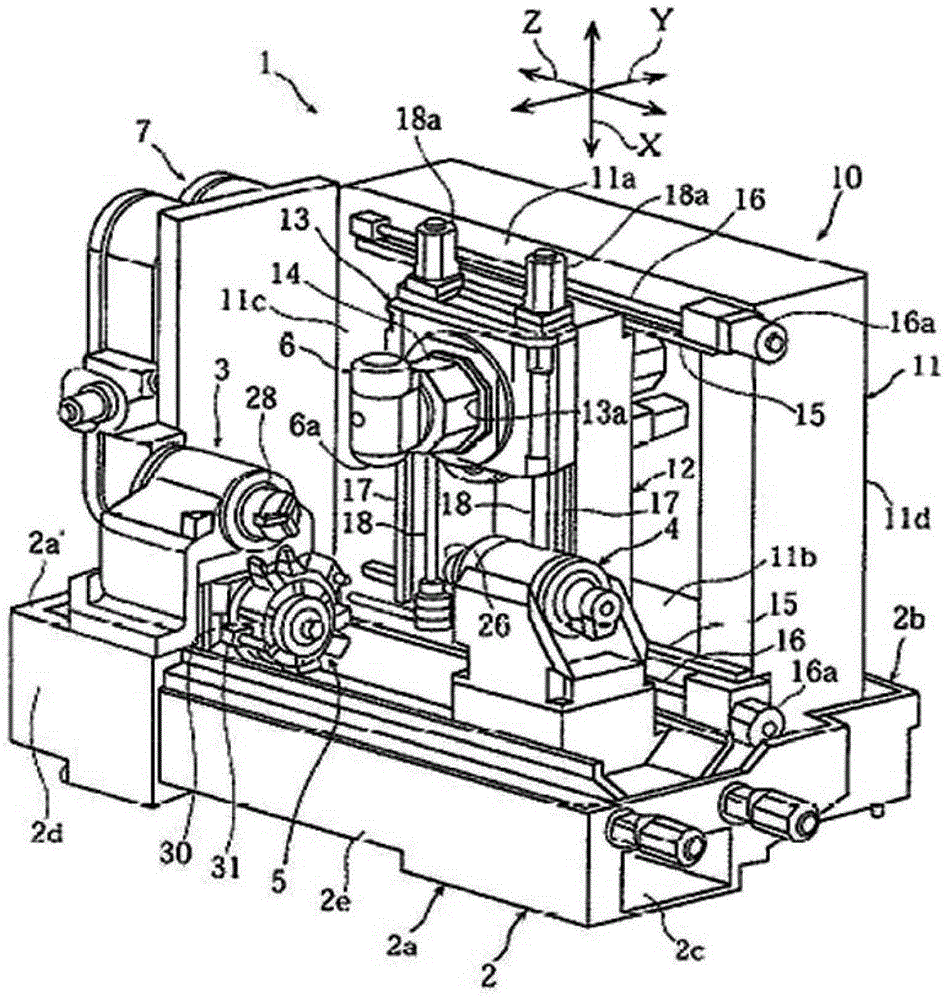

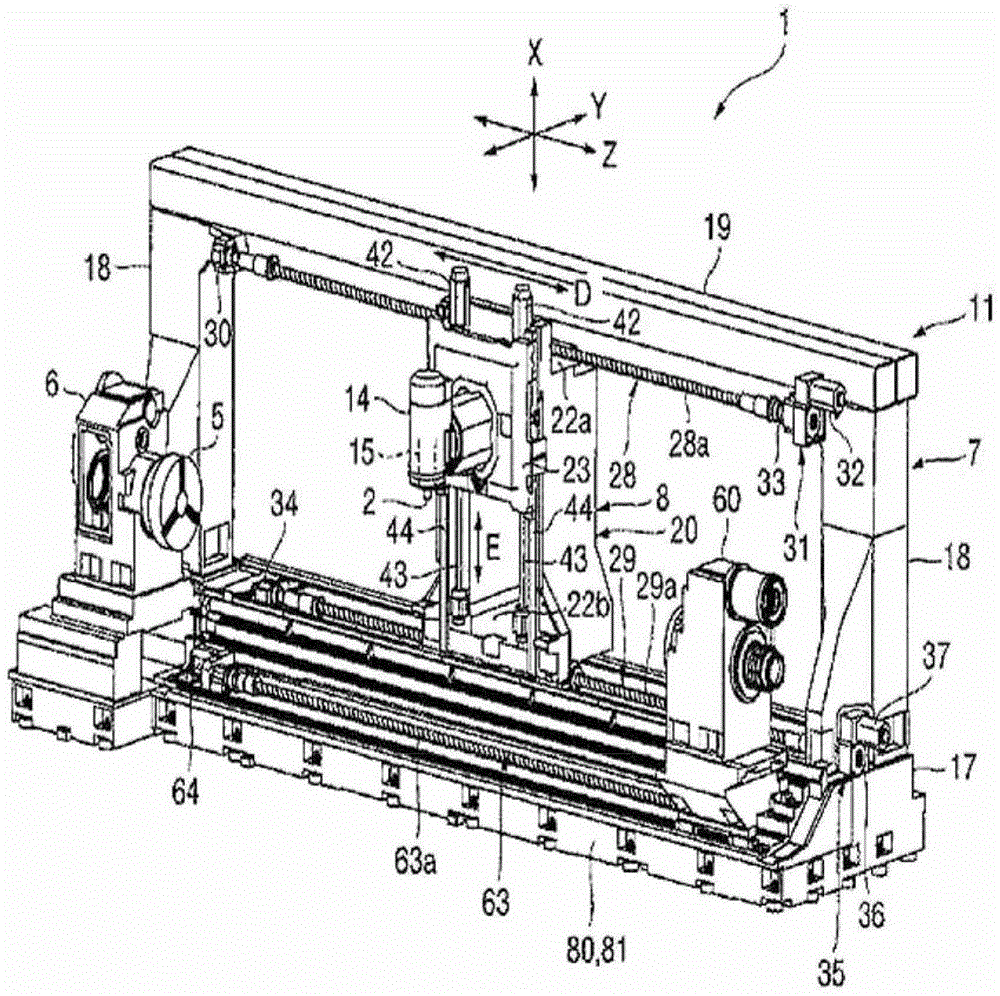

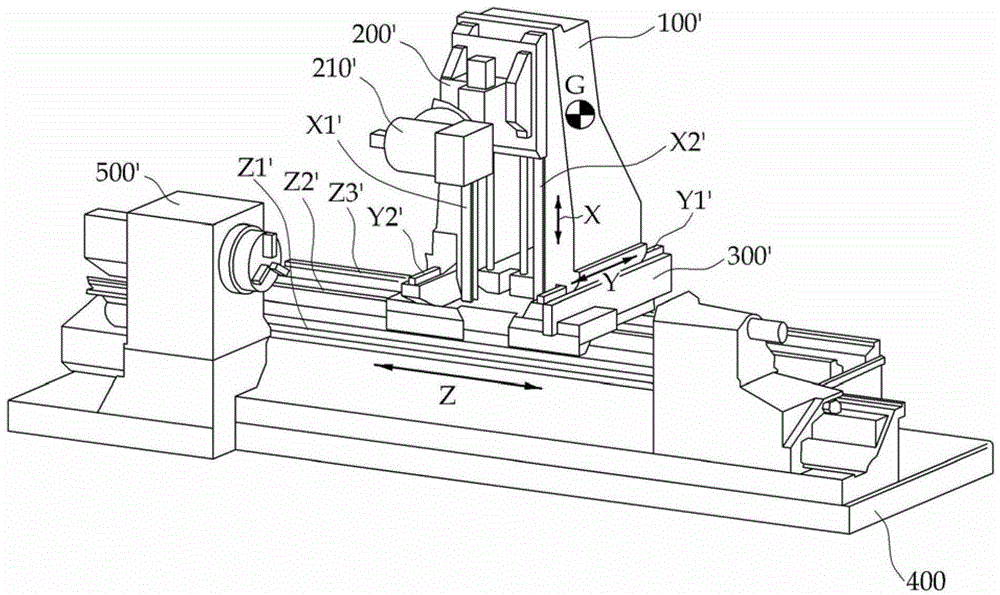

[0041] Next, a high-rigidity compound processing machine according to an embodiment of the present invention will be described with reference to the drawings.

[0042] In the following description, the "longitudinal direction" refers to the left-right direction or the Z-axis direction when the multi-function processing machine is viewed from the front. The "vertical direction" means the vertical direction or the X-axis direction perpendicular to the Z-axis of the multifunctional processing machine. The "front-rear direction" is perpendicular to the Z-axis and the X-axis of the multifunctional processing machine and refers to the depth direction or the Y-axis direction when the multifunctional processing machine is viewed from the front.

[0043] Figure 2a It is a structural diagram of the high-rigidity compound processing machine of the embodiment of the present invention.

[0044] like Figure 2a As shown, the composite processing machine according to the embodiment of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap