Method and device for the optical non-contact oscillation measurement of an oscillating object

A non-contact, vibration measurement technology, used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

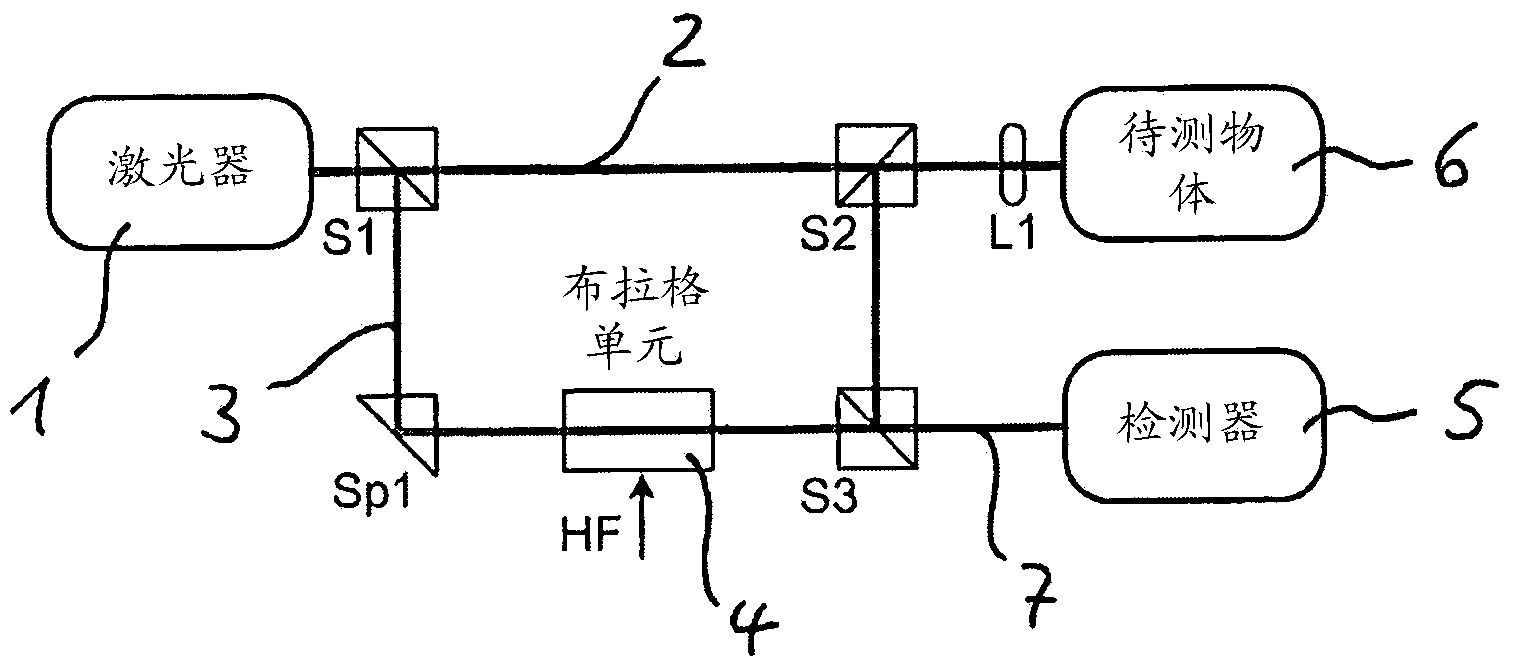

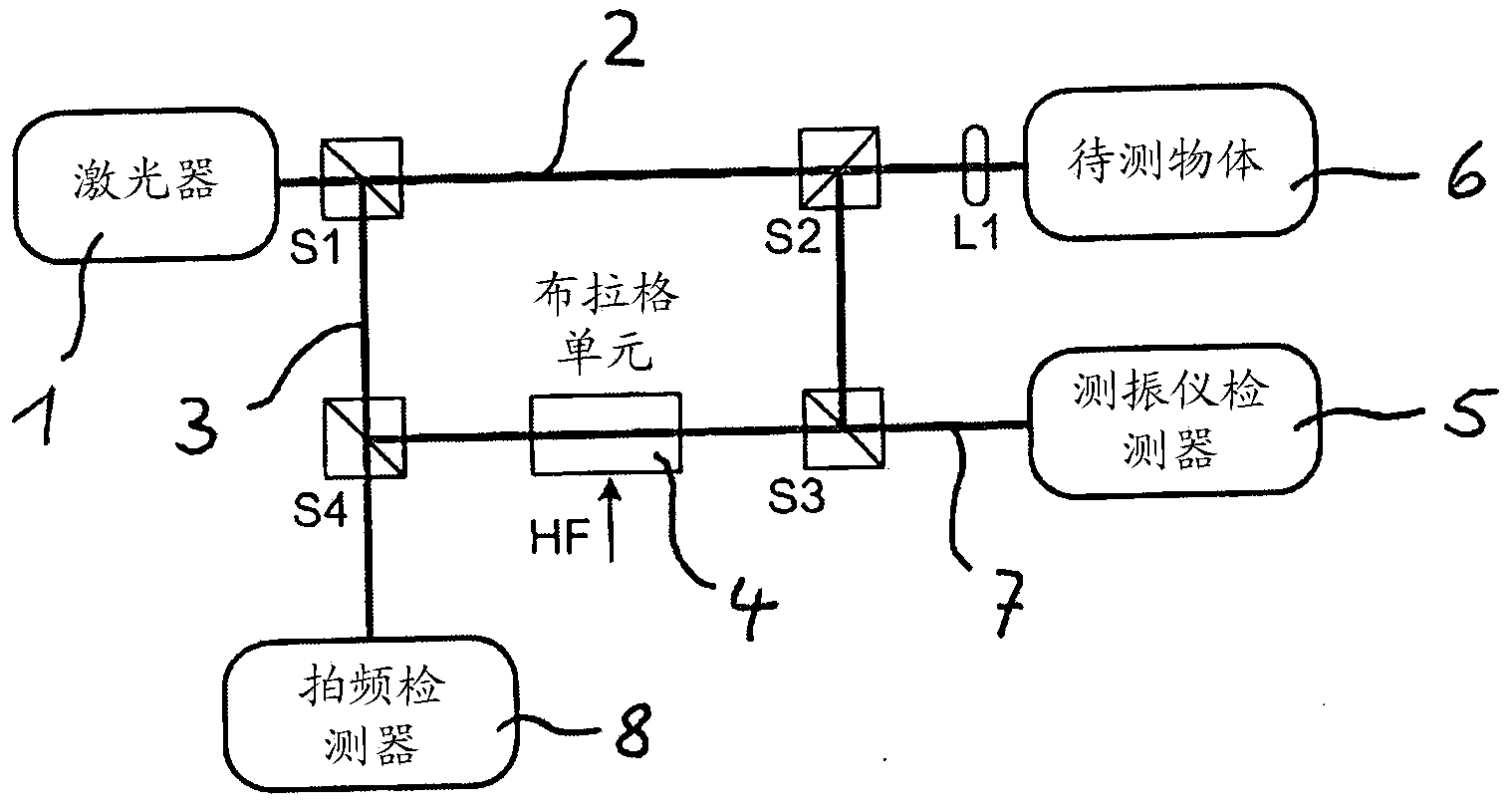

[0029] As an embodiment of the device of the present invention, a device comprising a laser Doppler vibrometer is described here, which in principle is as follows Figure 1a constituted as shown. In the present exemplary embodiment, a He-Ne laser 1 with a resonator length of 20.4 cm is used, the coherent light of which is split into a measuring beam 2 and a reference beam 3 by means of a first beam splitter S1 . The reference beam 3 is guided via the mirror Sp1 through the Bragg cell 4 , which here acts as an acousto-optic frequency instrument, and through a further beam splitter S3 to the optical detector 5 . The Bragg unit 4 then shifts the frequency of the reference signal 3 by typically 40 MHz.

[0030] Measuring beam 2 is conducted via second beam splitter S2 and λ / 4 plate L1 to vibrating test object 6 . The surface of the object 6 to be measured scatters back the measurement beam 2 . The returned measuring beam is reflected in the second (polarizing) beam splitter S2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com