Five-axis full-automatic rounding machine

A fully automatic, rolling machine technology, applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problems that it is difficult to meet workpieces with different diameters, the structure of the rolling machine is complex, and the scope of use is limited, reaching the scope of use wide, simple structure, and convenient replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

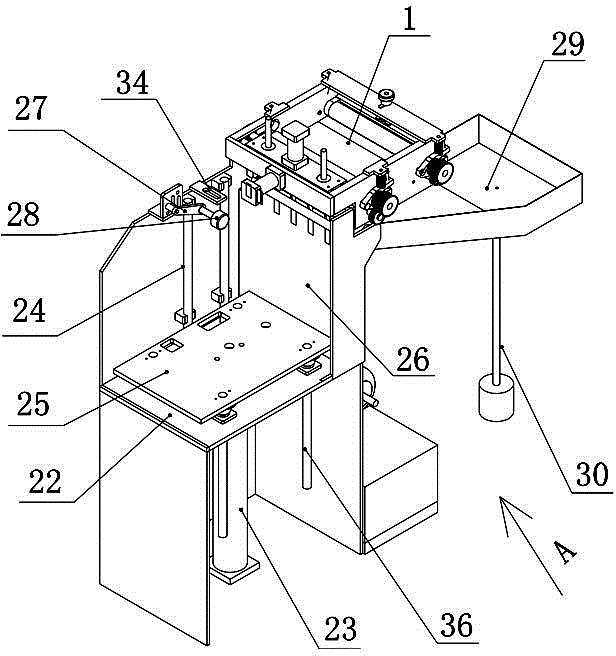

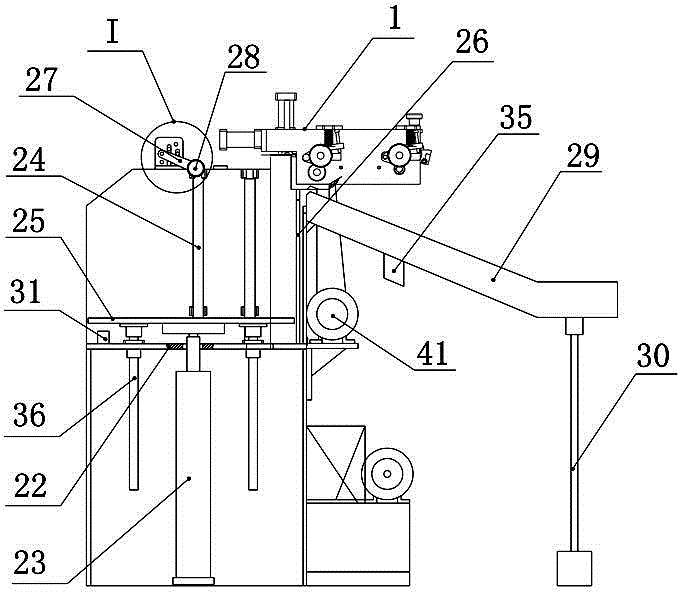

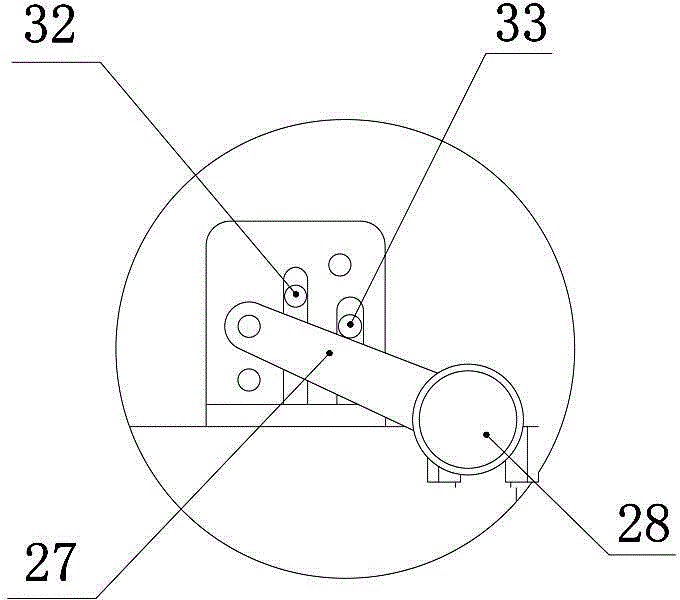

[0019] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the five-axis automatic rounding machine of the present invention includes a fuselage, a machine head 1 and a power drive system and a control system, and is located on the fuselage The feeding port and the discharging port of the head 1 are respectively provided with a feeding mechanism and a discharging mechanism, and the head 1 includes a feeding mechanism and a rolling mechanism arranged on the frame 2, and the feeding mechanism and the rolling mechanism The front and rear pair of rollers formed by the front upper roller 3, the front lower roller 4, the rear upper roller 5, and the rear lower roller 6 are arranged between the front upper roller 3 and the front lower roller 4, and the rear upper roller 5 and the The rear and lower rollers 6 are all connected by gear meshing transmission, the front and rear pair of rollers are connected by a synchronous belt and a guide plate 7 is arranged at their junction, the front lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com